| Posted: Apr 23, 2007 | |

High performance electronics and sensors on flexible plastic chips |

|

| (Nanowerk Spotlight) The fabrication of electronic devices on plastic substrates has attracted considerable recent attention owing to the proliferation of handheld, portable consumer electronics. Plastic substrates possess many attractive properties including biocompatibility, flexibility, light weight, shock resistance, softness and transparency. Achieving high performance electronics or sensors on plastic substrates is difficult, because plastics melt at temperatures above 120 degrees C. Central to continued advances in high-performance plastic electronics is the development of robust methods for overcoming this temperature restriction. Unfortunately, high quality semiconductors (such as silicon) require high growth temperatures, so their application to flexible plastics is prohibited. A group of researchers at the California Institute of Technology now showed that highly ordered films of silicon nanowires can be literally glued onto pieces of plastic to make flexible sensors with state-of-the-art sensitivity to a range of toxic chemicals. These nanowires are crystalline wires made out of doped silicon – the mainstay of the computer industry. By etching nanowires into a wafer of silicon, and then peeling them off and transferring them to plastic, they developed a general, parallel, and scalable strategy for achieving high performance electronics on low cost plastic substrates. | |

| "Our recent paper combines a number of 'firsts' into one piece of work" Dr. Michael McAlpine explains to Nanowerk. "For example, while highly aligned nanowires have been assembled on rigid substrates using a variety of methods, this is the first time that such well-ordered, densely packed films have been assembled on pieces of flexible plastic. This achievement opened the door to accomplishing another first: an 'electronic nose' composed of nanowire device arrays on flexible plastic, with state-of-the-art sensitivity. Our work was thus motivated by the challenge of overcoming the scientific hurdles to these achievements, the commercial possibilities of these advances, and concerns for health and safety of the general public." | |

| McAlpine, a post-doc in the Heath Research Group at Caltech, is first author of a recent paper in Nature Materials titled "Highly ordered nanowire arrays on plastic substrates for ultrasensitive flexible chemical sensors" | |

|

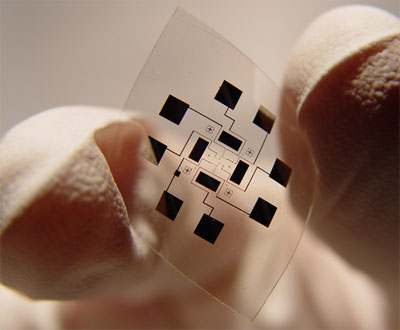

Photograph of the flexible sensor chip (Image: Heath Group, Caltech) |

| The Caltech researchers' approach to fabricate electronic devices on plastic substrates is based on dry-transfer methods involving the relocation of semiconductor materials or fully fabricated devices from inorganic substrates to plastic using poly(dimethylsiloxane) (PDMS) stamps or soluble glues. Dry transfer has been used to print a variety of photolithographically defined semiconductor microwires onto plastic. | |

| The dry-transfer method is particularly interesting where highly ordered structures are involved because, in principle, morphology is preserved by the transfer procedure. Yet, to date, achieving highly ordered, high-performance nanowire electronic circuits on plastic substrates has not been demonstrated. | |

| "We previously reported ("Ultrahigh-Density Nanowire Lattices and Circuits") on the superlattice nanowire pattern transfer (SNAP) approach for achieving highly regular arrays of metal and semiconductor nanowires" says Professor James R. Heath. "Here, we show that SNAP nanowire arrays can be transferred onto plastic substrates using a simple, parallel and scalable transfer process under ambient conditions. Nanowire organization is retained over large areas, and the printed nanowires yield excellent performance as both field-effect transistors (FETs) and as vapor sensors." | |

| FETs fabricated from the transferred wires using standard microprocessing techniques yield large on/off ratios and low-power operation. Sensor arrays on bendable plastic exhibited sensitivities comparable to the best nanotube and metal-oxide nanowire devices on Si substrates. | |

| "When we exposed these films to vapors of the hazardous pollutant NO2 (car exhaust), the plastic sensors detected concentrations as low as 20 parts-per-billion (ppb) in air" says McAlpine. "This performance is competitive with the very best sensors on rigid substrates, and is less than half the EPA?s health exposure metric (53 ppb). These results should be appealing to both scientists and average consumers alike, by providing a new platform for lightweight and portable sensors." | |

| The researchers believe that the results presented in their paper could have far-reaching impact on a host of sensing and medical applications. | |

| "Obtaining such high sensitivity sensors on plastic substrates is truly a niche area for nanowires, and unprecedented in the literature" says McAlpine. "Immediate applications include highly portable chemical and biological threat detectors, and real-time pollution regulators. More intriguingly, since plastic is biocompatible, the possibility exists for fully implantable or wearable continuous health monitoring systems." | |

| Furthermore, the low power/heat dissipation and high sensitivity of these devices coupled with the inherent biocompability of the plastic substrates may have applications in continuous in vivo biomolecular monitoring. | |

| The most significant challenge the Caltech scientists are facing in this area is developing the ability to detect chemicals with high specificity. Indeed, preliminary results since submission of this work suggest that selectivity towards small molecules in the gas phase is dramatically increased simply by chemically modifying the nanowire surfaces with recognition agents. | |

| "We envision that such high specificity / high sensitivity sensors can be used for continuous monitoring of human breath for specific biomarkers of diseases ranging from lung cancer to heart disease" says McAlpine. "Diagnosing such diseases normally requires highly invasive procedures, but evidence suggests that key biomarkers of oxidative stress (such as can arise from cancer) can be sensed in the breath, but they present in sub-parts-per-million quantities. Other than using cumbersome gas chromatography/mass spectography, there may not be another way to electrically detect such small, relatively unreactive molecules in the breath than our nanowire sensors." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.