| Posted: Apr 12, 2011 | |

Shooting videos in the nanoworld to observe nanoscale processes |

|

| (Nanowerk Spotlight) Life as we know it is dominated by friction, the interaction between moving objects. Friction controls our everyday lives, from letting us walk to work, to holding a cup of tea. Friction forces act wherever two solids touch. In simple terms: friction is a force that slows things down (this is one reason why you can't have a perpetuum mobile). In scientific terms: friction between two surfaces is caused by energy loss as atoms from the opposing surfaces smash against each other (and in extreme cases of course, surface damage). In the presence of an attractive/adhesive force the atoms are in intimate contact and much energy is lost in forcing the atoms to slide past each other. | |

| Although friction has been investigated for hundreds of years – in the 15th century, Leonardo da Vinci was the first to enunciate two laws of friction – it is surprisingly difficult to examine how friction works at the nanoscale level due to the sheer difficulty of bringing nanoscale objects into contact and imaging them at the same time. | |

| Researchers have now demonstrated the ability to bring nanoscale objects together, rub them repeatedly across one another and see how friction changes nanosized materials in real time. | |

| "We were able to observe how solid objects breakup into nanoparticles, and even form tiny nanoscale liquid droplets from localized frictional heating" Beverley Inkson, Professor of Nanomaterials at the University of Sheffield's NanoLAB, tells Nanowerk. | |

| This work has been carried out with Aiden Lockwood as part of the EPSRC Basic Technology programme in Nanorobotics where Inkson is project director, together with collaborators K Anantheshwara and MS Bobji as part of a British Council UKIERI exchange programme. | |

| Many everyday and industrial objects suffer damage due to friction, and understanding how damage occurs with time is fundamental to trying to design new materials that are resistant to damage, last longer and are therefore better value for us and the environment. | |

| This dynamic imaging of nanoscale friction represents a significant breakthrough for the understanding of how materials wear down and the development of friction resistant micro- and nanodevices. | |

| Most studies of friction have been on objects that can be examined with optical microscopes. But as the structure of objects we use becomes smaller, shrinking from the microscale down to nanoscale objects that can only be seen with powerful electron microscopes, it is very difficult to watch friction at work. It is very important to understand nanoscale friction because the wear of many every-day objects, such as wheels, are actually controlled by nanoscale effects at their outer surfaces. | |

| Also, the influence of friction can become much bigger for smaller things, because tiny objects have more of their atoms lying near the surface which can be pushed around by contact with another object. Squashing, heating and damaging the surface of nano objects can change their behavior completely, which could be very bad news for new nanotechnologies such as nanomachines and nanofluidics with tiny moving parts. Research on nanoscale wear ("Achieving ultralow nanoscale wear of one atom per micrometer") and on reducing friction at the nanoscale have therefore become important research areas (see "Slip sliding away in the nanoworld"). | |

| In their new work, reported in a recent edition of Nanotechnology ("Friction-formed liquid droplets"), Inkson and her collaborators were trying to observe 'friction in action' at the nanoscale, with dynamic in situ imaging of interacting surfaces, nanoparticles and nanoliquids. | |

|

|

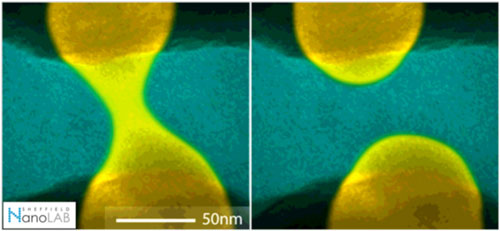

| A friction-formed liquid gallium nanobridge, stretched between diamond (top) and aluminium (bottom) surfaces. Slight movement of the diamond away, breaks the bridge forming two liquid metal droplets. (Image: Beverley Inkson and Aiden Lockwood, NanoLAB, University of Sheffield | |

| The team achieved this by building a special nanorobotic device – a TEM triboprobe – which can move and repeatedly scratch materials with nanoscale resolution inside an electron microscope fitted with a digital camera to record the friction on video. The development of the TEM triboprobe has been funded by the UK EPSRC Basic Technology Programme designed to develop fundamental new technologies for future science. | |

| "We have demonstrated the power of the technique by looking at how an automotive aluminium alloy changes with nanoscale rubbing," says Inkson. "Repeated scratching with a diamond caused tiny nanoparticles to break off. For the first time, it was observed that liquid could also be generated by atoms diffusing around in the friction hot-spot, and coalescing to form nanoscale droplets." | |

| Inkson points out that in situ TEM tribology at the nanoscale has many exciting potential applications in nanoscience and nanotechnology: "The ability to video how surfaces break-up at the nanoscale will help us understand how to improve materials for wear-resistance and develop better nanodevices, medical implants and surface coatings. Imaging how groups of nanoparticles interact in real-time with surfaces and liquids will help us understand how abrasives and lubricants work, which is critical in industrial applications such as car engines." | |

| She adds that TEM tribology also offers a new route to investigate the interaction and mechanics of nanoscale liquids droplets, which is an exciting field for nanofluidics and lubricant applications. | |

| "As our ability to manipulate matter at the nanoscale increases, it is a very big challenge for the future to understand how friction works in very complicated three-dimensional materials and devices," says Inkson. "If the pioneer of friction, Leonardo da Vinci, was alive today he would probably be amazed at the challenges and opportunities of nanoscale friction." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|