| Posted: Jun 10, 2011 | |

Fabricating polymer tandem solar cells with a graphene-based conductive glue |

|

| (Nanowerk Spotlight) Graphene oxide (formerly known as graphite oxide but now riding the sexy coattails of graphene) is a compound of carbon, oxygen, and hydrogen obtained by treating graphite with strong oxidizers. The material has attracted substantial interest as a possible intermediate for the manufacture of graphene. But apart from making graphene, graphene oxide itself itself is a fascinating material that has many intriguing properties. | |

| In a Nanowerk Spotlight last year, we reported on work by Jiaxing Huang's research group at Northwestern that showed that graphene oxide can act like a surfactant. Huang and his team have been interested in graphene oxide from a soft material angle, studying it as polymer, colloid, liquid crystal, and membrane. | |

| In a new paper, the Northwestern team discovered that adding graphene oxide (GO) can greatly increase the solution viscosity and solid state conductivity of conductive polymer poly(3,4-ethylenedioxythiophene): poly(styrenesulfonate) (PEDOT:PSS), essentially resulting in a graphene-based conductive glue. | |

| "Graphene oxide can be viewed as a two-dimensional, random diblock copolymer with distributed nano graphitic patches and highly oxidized domains," Huang explains to Nanowerk. "Therefore, it should be capable of guiding the assembly of other materials through both π-π stacking and hydrogen bonding. Since PEDOT:PSS is the most widely used conducting polymer, we chose it as a model system. And indeed we see strong interaction between graphene oxide and the PEDOT polymer that significantly alter the polymer properties." | |

| Surprisingly, as the researchers report in their paper in the May 26, 2011 online edition of Journal of the American Chemical Society ("Sticky Interconnect for Solution-Processed Tandem Solar Cells"), the insulating graphene oxide makes PEDOT much more conductive by altering its chain conformation and morphology. | |

|

|

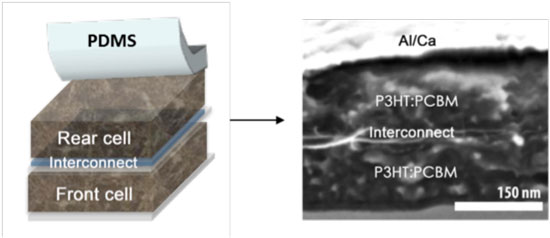

| The sticky GO/PEDOT interconnect makes it possible to directly glue a PDMS supported rear cell onto a prefabricated front cell. The PDMS substrate can be peeled off to deposit metal electrodes for completing the device. The cross-sectional view of the device is shown in the SEM image. (Image: Huang Group, Northwestern University) | |

| Huang and his team demonstrated that the GO/PEDOT gel can function as a metal-free solder for creating mechanical and electrical connections in organic optoelectronic devices. As a proof-of-concept, they fabricated polymer tandem solar cells by a direct "gluing" process enabled by the sticky GO/PEDOT film. | |

| Tandem solar cells are multi-junction photovoltaic devices, in which two sub-cells are stacked to achieve higher overall solar absorption (see for instance: "Tandem organic solar cells offer a path to higher efficiencies"). In parallel to the rapid progress in the material design and engineering of the light absorbing layer, tandem device architectures have attracted great interest for organic solar cells. | |

| A major challenge of making organic tandem solar cells, especially solution-processed ones, is the interconnect layer that electrically connects but physically separates the two sub-cells. For example, it needs to be made with sufficient conductivity, high transparency, low surface roughness, dense coverage, and high mechanical and chemical stability. More importantly, the interlayer material needs to have orthogonal processability to maintain the stacking integrity and avoid intermixing between the different layers in the device. It should be processed in a solvent that will not affect the underlying sub-cell, and at the same time it should withstand the solvent used to deposit the top sub-cell. These material processing challenges have placed a major roadblock towards the widespread study of of solution-processed tandem solar cells. | |

| Huang says that the water-processable GO/PEDOT gel associated with the direct gluing process that his group has developed can potentially eliminate the constraint imposed by orthogonal processability. | |

| "The glue could make it a lot easier to construct tandem solar cells with different combinations of solution processable materials to achieve high efficiency" he points out. "The water-based sticky interconnect and the associated adhesive lamination process could transform the serial layer-by-layer fabrication of tandem devices into a parallel mode, in which the subcells can be independently fabricated and adjusted to balance their photocurrents for achieving high efficiency. This serial-to parallel transition can reduce the number of sequential fabrication steps, thus significantly improving the yield of devices." | |

| More generally, the glue is well suited for mechanically and electrically connecting parts in organic electronic devices. Tandem solar cells turn out to be a very suitable system to demonstrate this application. The graphene oxide based glue should integrate well with solar cells using other polymers, small organic molecules, or even inorganic nanoparticles. | |

| "This is another example from the Huang group of creating new possibilities from a simple and ingenious material innovation," comments Professor Kian Ping Loh of National Univeristy of Singapore. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|