| Posted: Jun 27, 2011 | |

Using a simple pen, you can literally write electronics on paper |

|

| (Nanowerk Spotlight) The silicon chip took over forty years to approach a $300 billion business today. A new form of electronics – printed electronics – will hit that figure in half the time because, unlike the silicon chip, it subsumes electrics such as lighting, batteries, solar cells and heaters, not just electronics. It is usually achieved by printing and its most vital characteristic is physical flexibility. Printed electronics is one of the most important new enabling technologies. It will have a major impact on most business activities from publishing and security printing to healthcare, automotive, military and consumer packaged goods sectors. | |

| One enabling technology for printed and flexible electronics devices is the use of a special silver nanoparticle ink that allow the patterning of silver microelectrodes by omnidirectional printing. In a previous Nanotechnology Spotlight, we reported on an example of how researchers at the University of Illinois at Urbana-Champaign (UI) used this ink for the conformal printing of 3D electrically small antennas. | |

| Taking an important step towards enabling desktop manufacturing – or personal fabrication – using very low cost, ubiquitous printing tools, the UI team now demonstrated a pen-on-paper approach as a low-cost, portable fabrication route for printed electronic and optoelectronic devices. | |

| Paper has emerged as a focus area for researchers developing innovative techniques for printed basic electronics components (see for instance: "Paper-based metamaterial biosensor"). Paper is widely available and cheap, it is lightweight, biodegradable, and you can roll and fold it like you want. Putting a pen to paper is one of the first things every child learns at school. Imagine combining this basic tool with modern electronics... | |

|

|

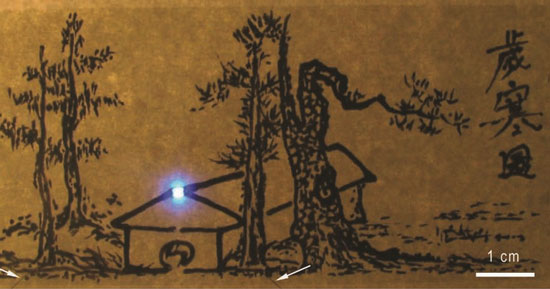

| Optical image of conductive electronic art. An electronic sketch of the famous painting "Sae-Han-Do" by Jung Hee Kim is drawn using a silver ink-filled rollerball pen. The yellow-grey background is first printed on Xerox paper using a desktop printer, and then the trees, house, and Chinese characters are hand-drawn. The printed silver features that overlap form a conductive network upon drying under ambient conditions. A surface-mount LED is placed in a gap that is left in the rooftop of the house. To form contacts, a drop of concentrated silver ink is used as a conductive adhesive. The LED is illuminated by using a 5 V battery as a power source and electrical leads located at the indicating arrows. (Reprinted with permission from Wiley-VCH Verlag) | |

| Reporting their findings in the June 20, 2011 online edition of Advanced Materials (Pen-on-Paper Flexible Electronics), the team demonstrates the fabrication of electronic art, flexible displays, conductive text, and radio frequency antennas with their technique. The printed features can withstand repeated bending and folding while maintaining high conductivity. The work was led by Jennifer Lewis, the Hans Thurnauer Professor of Materials Science and Engineering, Willett Faculty Scholar of Engineering, and Director, F. Seitz Materials Research Laboratory at the University of Illinois at Urbana-Champaign (UI), and Jennifer Bernhard, a professor in the Department of Electrical and Computer Engineering at UI. | |

| "Inks developed for pen-on-paper printing exhibit a lower conductivity than a bulk silver – however, our method allows one to conformally pattern conductive features onto rough substrates, such as paper, under ambient conditions," Lewis tells Nanowerk. "A key advantage is that the costly printers and printheads typically required for inkjet or other printing approaches are replaced with an inexpensive, hand held writing tool. Pen-based printing allows one to construct electronic devices 'on-the-fly'." | |

|

|

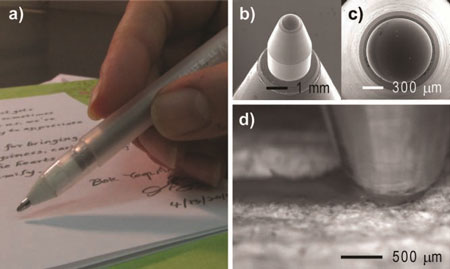

| a) Optical image of a rollerball pen loaded with a conductive silver ink. The background shows conductive text written on Xerox paper. b and c) SEM images of the side and top views of the rollerball pen. d) Optical image of the rollerball pen tip, captured during writing a conductive silver track on a Xerox paper. (Reprinted with permission from Wiley-VCH Verlag) | |

| "The pen-on-paper paradigm offers a unique approach to fabricating flexible devices by using a patterning instrument that is itself as ubiquitous and portable as the paper substrate," says Bernhard. "Rollerball pens are especially well suited for dispensing conductive inks due to their compatibility with liquids and gels." | |

| Central to the flexible electronics pen-on-paper approach – as with conventional writing on paper – is a silver ink that readily flows through the rollerball pen tip during writing, does not leak from, dry out, or coagulate within the pen, and is conductive upon printing under ambient conditions. The nanosilver ink synthesized by the UI team meets these attributes. | |

|

|

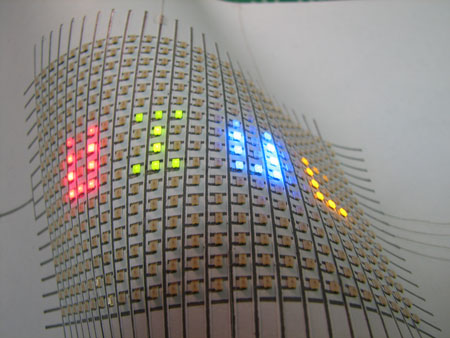

| Optical image of a flexible paper display containing a LED array (25 ? 16) on a Xerox paper. (Reprinted with permission from Wiley-VCH Verlag) | |

| The ink design strategy described above is quite general. Lewis says that, with little effort, it can be extended to other particle-based inks, including those based on oxide, semiconductor, and carbon building blocks. | |

| "We therefore envision that our pen-on-paper approach could be implemented for paper-based batteries, medical diagnostics and other functional devices." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|