| Posted: Sep 01, 2011 | |

Novel hydrogel-coated mesh is promising material for oil spill clean-ups |

|

| (Nanowerk Spotlight) Earlier this year, in the follow-up to the Deepwater Horizon oil spill in the Gulf of Mexico, we published a Nanowerk Spotlight on nanotechnology-based solutions for oil spills. Although the application of nanotechnology for oil spill cleanup is still in its nascent stage, it offers great promise for the future. In the last couple of years, there has been particularly growing interest worldwide in exploring ways of finding suitable solutions to clean up oil spills and deal with industrial oily wastewater through use of nanomaterials. Key for the success of these materials is a high separation capacity, with resistance to oil fouling, and that are easily recyclable. | |

| Oil/water separation is an interfacial challenge, and novel materials designed to possess special wettability have different interaction and affinity for oil and water, thus can realize the separation. | |

| "Until now, researches in this field all focus on materials with both hydrophobic and oleophilic properties," Lin Feng, an associate professor in the Department of Chemistry at Tsinghua University in Beijing, explains to Nanowerk. "Those materials realized filtration or absorption of oils from water selectively and effectively – the so-called 'oil-removing' type of materials. However, the oil-removing type of materials is easily fouled even blocked up by oils because of their intrinsic oleophilic property. The adhered oils, especially high-viscosity oils, seriously affect the separation efficiency after using for limited number of times. In addition, oils adhered or absorbed are hard to remove, which result in secondary pollution during the post-treatment process as well as a waste of both oil and oleophilic materials." | |

| In new work, Feng and a team os scientists from Beijing National Laboratory for Molecular Sciences and Beihang University, fabricated a novel superhydrophilic and underwater superoleophobic hydrogel coated mesh. As they reported in the August 17, 2011 online edition of Advanced Materials ("A Novel Superhydrophilic and Underwater Superoleophobic Hydrogel-Coated Mesh for Oil/Water Separation"), this new material can selectively separate water from oil/water mixtures such as vegetable oil, gasoline, diesel, and even crude oil/water mixtures effectively (more than 99 %) and without any extra power. | |

|

|

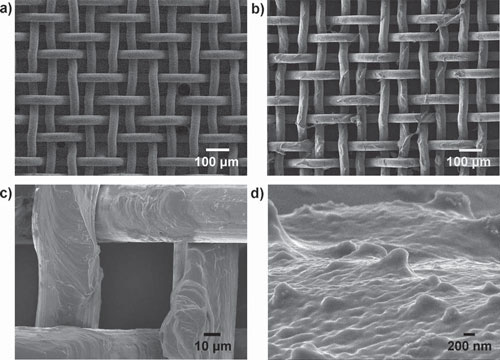

| SEM images of the PAM hydrogel-coated mesh prepared from a stainless steel mesh with an average pore diameter of about 50 µm. a) Large-area view of the uncoated stainless steel mesh. b) Large-area view of the PAM hydrogel-coated stainless steel mesh. c) Enlarged view of a single pore of the PAM hydrogel-coated stainless steel mesh. d) The higher magnifi cation image of one single wire on hydrogel-coated stainless steel mesh, in which the nanostructured papillae can be clearly observed. (Reprinted with permission from Wiley-VCH Verlag) | |

| Feng points out that during the separation process, the underwater superoleophobic interface with low affinity for oil drops prevents the coated mesh from fouling by oils, which makes the recycling of oil and materials easy. | |

| "Our novel 'water-removing' type of material has completely opposite wettability to traditional hydrophobic and oleophilic materials, thus overcomes the easy-fouling and hard-recycling limitations in essence," says Feng. "It is a new attempt to using special wettability to design next-generation materials for oil/water separation, which suggests attractive potential applications in industrial oily waste water treatments and oil-spill cleanup." | |

| Feng and her collaborators' research is focused on interfacial science, and for years they have been using their knowledge and techniques to help solve oil pollution problems. Back in 2004, their first work on this subject was published in Angewandte Chemie International Edition ("A Super-Hydrophobic and Super-Oleophilic Coating Mesh Film for the Separation of Oil and Water"). | |

| "However, during our research following this publication, we realized that oleophilic materials have limitations" says Feng. "Therefore, we tried to find a novel system to solve these problems and finally successfully developed this superhydrophilic and underwater superoleophobic system." | |

| For their novel material, the team coated a microstructured stainless steel mesh with a typical and environmentally friendly hydrogel material, nanostructured polyacrylamide (PAM) – resulting in a material that has completely opposite wettability to traditional hydrophobic and oleophilic materials. Its characteristics make it a good candidate for oil retention barriers of industrial outlet sewer pipes; oil fences in oil spill accidents; filtration devices for oil-polluted water; and separation of high-viscosity oils. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|