| Posted: Aug 17, 2007 | |

Nanotechnology bearings for next generation NEMS |

|

| (Nanowerk Spotlight) In the good old days, say 5,000 years ago, a bearing was simply the placement of tree trunks under the huge stone blocks that your worker army used to construct a pyramid. Since then, bearings have become a bit more sophisticated and are an essential part of much of today's machinery. Consequently, many kinds of bearings have been developed to suit particular purposes – sliding, rolling, fluid, or magnetic bearings, to name a few major categories. | |

| Bearings are now widely used for instance to reduce friction between shafts and axles or absorb the weight placed on moving parts and they are found in applications ranging from automobiles, trains and airplanes, computers, construction equipment, machine tools, to ceiling fans and roller skates. The same way that bearings have become an integral part of our modern world, they will also play an important role in the extremely miniaturized micro- and nanodevices of the future. | |

| Engineers will just have to come up with ingenuous ways to construct bearings at the nanoscale. Carbon nanotubes (CNTs) offer one possibility. Researchers have demonstrated that the relative displacements between the atomically smooth, nested shells in multiwalled carbon nanotubes (MWCNTs) can be used as a robust nanoscale motion-enabling mechanism. Even better, a group in Switzerland has demonstrated batch fabrication of such CNT bearings is possible. | |

| "Many in the field believe that one future for nanotubes will be as digital electromechanical logic elements in future computers" Dr. Bradley J. Nelson explains to Nanowerk. "There are genuine benefits over silicon, but there is a lot of work to do to get there. Our recently published work on batch fabrication of carbon nanotube bearings is one possible avenue, but there are other promising approaches, such as John Rogers' work at the University of Illinois at Urbana-Champaign on growing CNTs on quartz substrates (see our Nanowerk News article: "Linear arrays of nanotubes offer path to high-performance electronics"). | |

| Nelson is Professor of Robotics and Intelligent Systems at ETH-Zürich and is the director of IRIS, ETH's Institute of Robotics and Intelligent Systems. His group has successfully demonstrated the batch fabrication of nanoscale bearings using dielectrophoretically assembled MWNTs. | |

|

|

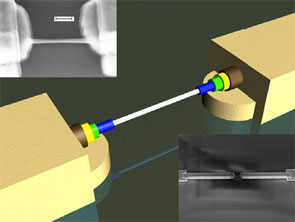

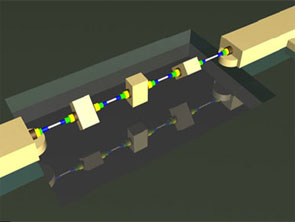

| (Left) Schematic diagram of the MWNT nanostructure. SEM images of the nanostructure at high and low magnification are provided in the top-left and bottom-right insets, respectively. The scale bar in the top-left inset represents 100 nm. (Right) Schematic illustration of high density MWNT rotary motors and independent bearings. (Reprinted with permission from IOP Publishing) | |

| The primary requirement for simultaneously engineering an array of nanotubes, while applying a common electrical bias, is that the MWNT-based nanostructures are created with nearly identical electrical circuit resistance and heat transport conditions. This causes uniform Joule heating across the array and etches all nanotubes in parallel to fabricate bearings. | |

| "The biasing approach we used results in bearing formation by electric breakdown with high-yield and low cycle-time" says Nelson. "In addition, this technique lends itself to create sophisticated MWCNT shell architectures and high density bearings. Due to its compatibility with conventional silicon micro/nanomachining steps, further processing can create more complex nanostructures." | |

| Using the nested cylinder structure of multi-walled CNTs to construct bearings has been practiced in labs for several years. A 2000 paper in Science, for instance, reports the controlled and reversible telescopic extension of MWCNTs, thus realizing ultralow-friction nanoscale linear bearings and constant-force nanosprings. | |

| Nelson explains that the most commonly used methods to create nanotube bearings include electrically controlled vaporization of shells and mechanical shell destruction, either by manipulation or electrostatically actuated metal paddles. "Of these techniques, current-driven shell engineering is more promising since it is simpler, provides better control over breakdown location and can realize fundamental architectures suited for diverse nanoscale devices" says Nelson. | |

| In this method, electrically induced Joule heating causes high nanotube temperatures – as high as 2000°K – which results in defects such as kinks and holes that are initiated at MWNT mid-lengths and result in individual shell removal in the region between contacting electrodes with associated drops in current. | |

| "Though prototype bearings and devices built using this method have recently proven concepts, the capability to modify the structure of MWNTs in parallel represents an important challenge towards their eventual manufacturability and commercialization" says Nelson. "In our group we have scaled this barrier and demonstrated that the current-driven breakdown technique, using a novel biasing approach to ensure high-yield and low cycle-time, can engineer suitably designed MWNT nanostructures in parallel to create arrays of bearings with different architectures." | |

| "It is important to note that this is the first successful fabrication of bidirectional core?shell mechanisms which have been modeled extensively, and the suitability of our technique for batch fabrication further enhances the significance of this result" says Nelson. "Another possible application of this structure is for electromechanical switches and non-volatile memories based on inter-segment gap closing by electrostatically attracted cores. We are currently investigating the performance characteristics of these structures with initial results pointing to core actuation at voltages between 1 and 6 V." | |

| Nelson expects this robust method to form fundamental electromechanical building blocks to enable the manufacturability and commercialization of next generation nano-electromechanical systems (NEMS). "We anticipate this method for constructing electromechanical building blocks to be a fundamental unit process for manufacturing future NEMS with sophisticated architectures and to drive several nanoscale transduction applications such as GHz-oscillators, shuttles, memories, syringes and actuators." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.