| Posted: Jul 19, 2012 | |

The first printable magnetic sensor that relies on the giant magnetoresistive effect |

|

| (Nanowerk Spotlight) Printed electronics has emerged as a key research field to meet the requirements of large area and cost-efficient production. The field of modern electronics is very general and includes not only printable interconnects, but also optoelectronics and magnetoelectronics. In this respect, cost-efficient versatile electronic building blocks, such as transistors, diodes and resistors, are already available as printed counterparts of conventional semiconductor elements. However, the element responding to a magnetic field, which is highly demanded for printable electronics, has not yet been realized and printable electronic sensors and contactless switches operating in combination with magnetic fields have not been reported so far. | |

| By adding a magnetic sensor to printable electronic circuitry, active intelligent packaging, post cards, books or promotional materials that communicate with their surroundings could be envisioned. The printable magnetic sensor would act as a contactless switch in a complex electronic circuit consisting of, e.g. transistors, capacitors and batteries. Combined with RFID tag and printed antenna, integrated functions of the printed electronic circuit like data exchange can be externally triggered by a magnetic field. | |

| The fabrication of printable magnetoelectronics is challenging, mainly due to the lack of appropriate sensing compounds working at ambient conditions. In order to be in line with the concept of printable electronics, magnetic sensors should satisfy the following basic requirements: low-cost, high-volume production on large areas of standard printing materials, disposability and processability. | |

| In new work, researchers in Germany have successfully overcome most of these issues. Reporting their work in the July 3, 2012 online edition of Advanced Materials ("Printable Giant Magnetoresistive Devices"), a team led by Professor Oliver G. Schmidt at IFW Dresden, fabricated the first printable magnetic sensor that relies on the giant magnetoresistance (GMR) effect. The developed magneto-sensitive ink can be painted on any substrate – such as paper, polymers, ceramics, and glass – and retains a GMR ratio of up to 8% at ambient conditions. This value is beyond the state of the art. | |

|

|

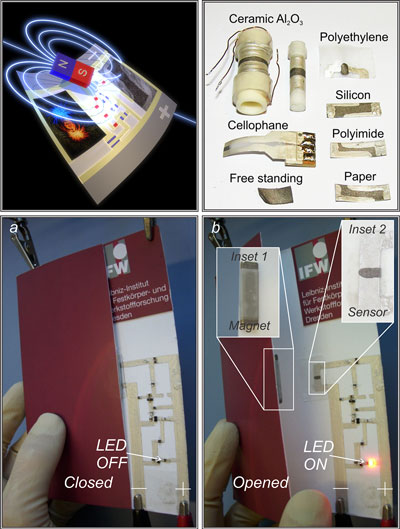

| Top left: A printable magnetic sensor would act as a contactless switch in a complex electronic circuit. Top right: The developed magneto-sensitive ink can be painted on any substrate, such as paper, polymers, ceramics, and glass. Bottom left and right: The LED ON/OFF state is triggered by a permanent magnet that modifies the resistance of the printable magnetic sensor and alters the current flow through the LED. (Image: D. Karnaushenko, IFW Dresden) | |

| "Our preparation process uses standard sputter deposition, milling and mixing machines for high yield production, demonstrating the suitability of the printable devices for large scale industrial production," Daniil Karnaushenko, PhD student working on the project, tells Nanowerk. "We realized the transfer of the magnetic sensor to different substrates by regular painting, although there are no limitations to use other methods, such as conventional and modern digital printing including roll-to-roll, flexography, spray coating and screen printing. The separated ink preparation from the printing process avoids special conditioning regarding substrates and photolithography, which renders the production cost-efficient and reliable." | |

| The team demonstrated the performance of a printable GMR sensor by integrating it into a hybrid electronic circuit, in this case an amplifier with a light emitting diode (LED), fabricated on the paper of a postcard. The LED on/off state is triggered by a permanent magnet that modifies the resistance of the printable magnetic sensor and alters the current flow through the LED. | |

| "Our demonstrator with a magnetic switch printed on a postcard suggests that the vision of interactive fully printable electronics can become reality," says Dr. Denys Makarov, leader of the group "Magnetic Nanomembranes" at the IFW Dresden. | |

| He cautions that there are several issues which still need to be solved. Among them the most crucial are high-volume production of magneto-sensitive ink and demonstration of large-scale printing of the ink. | |

| "There are strategies that will help us to overcome these aspects" says Makarov. "To increase the produced amount of the ink it is instructive to choose different support materials. The best would be to switch from the silicon-based substrates to large-area polymer sheets. We already demonstrated that magnetic sensors with good GMR response can be prepared even on regular transparency [1] or rubber [2,3]." | |

| Regarding large-scale printing capabilities, Makarov notes that, at the moment, they apply regular painting process to bring the magneto-sensitive ink to the surface; but that other methods such as roll-to-roll, flexography, spray coating and screen printing can be applied. "However, the size of the GMR flakes in the ink as well as the viscosity of the ink has to be optimized separately for each of these printing processes. In this respect, more investigations are required to understand the influence of the size of GMR flakes on the resulting GMR response of the magneto-sensitive ink. Furthermore, different binder solutions have to be tested to adjust the viscosity and conductivity of the ink." | |

| References | |

| [1] Y.-F. Chen, Y. F. Mei, R. Kaltofen, J. I. M?nch, J. Schumann, J. Freudenberger, H. J. Klau?, O. G. Schmidt: ?Towards flexible magnetoelectronics: Buffer-enhanced and mechanically tunable GMR of Co/Cu multilayers on plastic substrates?, Adv. Mater. 20, 3224 (2008). | |

| [2] M. Melzer, D. Makarov, A. Calvimontes, D. Karnaushenko, S. Baunack, R. Kaltofen, Y. Mei, and O. G. Schmidt: ?Stretchable magnetoelectronics?, Nano Letters 11, 2522 (2011). | |

| [3] M. Melzer, D. Karnaushenko, D. Makarov, L. Baraban, A. Calvimontes, I. M?nch, R. Kaltofen, Y. Mei, and O. G. Schmidt: ?Elastic magnetic sensor with isotropic sensitivity for in-flow detection of magnetic objects?, RSC Advances 2, 2284 (2012). | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|