| Posted: Sep 06, 2012 | |

A lithography technique for fabricating complex, free-floating protein structures |

|

| (Nanowerk Spotlight) Multiphoton lithography (MPL) is a microfabrication technique used to create three-dimensional (3D) microscale objects with complex geometrical arrangements. Of the various chemistries used to produce solid forms in MPL, protein photocrosslinking has been of particular value in biological applications. | |

| In new work reported in the August 24, 2012 online edition of Advanced Functional Materials ("Multiphoton Lithography of Unconstrained Three-Dimensional Protein Microstructures"), researchers at the University of Texas at Austin (UT), led by Jason B. Shear, a professor in the Dept. of Chemistry & Biochemistry, have now described a strategy for creating a nearly unlimited range of microforms from crosslinked protein, including structures composed of multiple proteins. They also describe MPL microfabrication of complex unconstrained objects using high-viscosity protein-based reagents. | |

| "Protogels are prepared from a range of proteins and can be used to fabricate crosslinked microstructures with the capacity to retain native protein activity," Eric Spivey, a graduate student in Shear's group and the paper's first author, tells Nanowerk. "The use of protogels as a reagent for MPL greatly extends the geometric possibilities for biological microstructures, and as such, opens opportunities for a range of innovative biomedical tools." | |

| In previous uses of MPL with liquid precursor reagents, the potential for object drift – and consequent distortion – during the MPL process has required that microforms be constructed in integral contact with an immobile surface. | |

| To avoid drift during fabrication of microforms that are not in integral contact with a surface, the UT team developed a methodology for producing high-viscosity protein-based reagents, or "protogels". These materials allow the fabrication of protein-based objects that retain rotational and translational degrees of freedom. | |

|

|

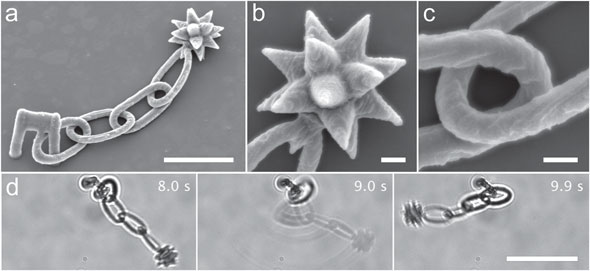

| Multiphoton lithography (MPL) of a partially-constrained microstructure fabricated from a BSA protogel. a) Scanning electron microscopy (SEM) image of a BSA morningstar that contains four chain links and an 18-point spiked star. The morningstar is connected to the coverglass using a microfabricated clip. All elements (star, chain and clip) of the structure are fabricated using a single mask sequence. Scale bar, 20 µm. b) SEM image showing detail of the star. The radius of curvature of the points is ∼ 0.5 µm. Scale bar, 3 µm. c) SEM image showing detail of two interlocked morningstar chain links. Scale bar, 2 µm. d) Time-lapse bright-fi eld sequence of the morningstar subjected to oscillatory fl ow. The chain freely responds to buffer convection, demonstrating that interlocked links are not fused. Images were extracted from Supporting Information Video 1; time stamp values correspond to the video. Scale bar, 30 µm. (Reprinted with permission from Wiley-VCH Verlag) | |

| In their paper, the team describes the development of a high-viscosity protein-based reagent that can be used to fabricate complex 3D microstructures that are not adhered to a surface. Shapes include chains of Möbius strips, paddle wheels, and unconstrained (free-floating) probes for bacterial motility. | |

| "Our technique offers a strategy for not only creating microscopic structures of essentially any imaginable shape, but for harnessing the attributes and functionality of biological materials within these objects," explains Shear. "The versatility of protein-based micromaterials provides opportunities for fabricating micromachines with tunable and spatially heterogeneous mechanical properties and environmental sensitivity, offering greater flexibility, for example, in designing devices such as micro-pumps and rotors. | |

| He adds that protein-based microparticles could prove useful in drug delivery, where recent studies have indicated that macrophage clearing of microscale particles via phagocytosis may be critically dependent on the object’s size and shape. | |

| "Currently, micro- and nanoscale hydrogels are limited to spheroids or simple geometric shapes including disks and pyramids," he says. "By systematically assessing cellular interactions with a much broader range of microparticle shapes, it may be feasible to tune drug-delivery vehicles to either minimize removal of drugs by macrophages, or, alternately, to target delivery to these cells." | |

| A complication using protogel to fabricate unconstrained microstructures arises from potential nonspecific adhesion of the microstructures to other objects in the environment. The researchers' current proof-of-concept studies did not investigate in detail the variables influencing attachment of protein-based materials. These factors may include molecular interactions, microstructure geometry, and local buffer flow. | |

| Spivey says that the team is confident that a systematic evaluation of attachment will identify approaches to mitigate unwanted interaction of micro-objects, e.g. addition of passivating agents or adjustment of pH. | |

| "We are now building on this work by exploring methods for “scaling up” our hydrogel microstructures, both in terms of microstructure size and in terms of time required for fabrication," he describes the team's current efforts. "Our goal in increasing the size of the objects is to achieve this without sacrificing feature resolution. This would allow MPL to be more potentially useful in areas such as tissue engineering and microfluidic devices. In our efforts to decrease the amount of time per object fabricated, we are exploring methods for using MPL-fabricated microstructures as master structures for PDMS molds, which could allow mass production of hydrogel microstructures for use in high-throughput bacterial and cancer cell studies." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|