| Posted: Oct 29, 2012 | |

High-tech band-aids |

|

| (Nanowerk Spotlight) In order to fabricate stimuli-responsive materials, researchers have shown a lot of interest in asymmetric materials such as modulated gels which consist of a controlled layer that is responsive to an environmental stimuli and a nonresponsive substrate layer. And while much effort has gone into creating free-standing films through layer-by-layer (LbL) assembly, relatively little attention has been paid to the asymmetric properties or functionalization of the two surfaces of such free-standing layer-by-layer films. | |

| In new work, researchers have now reported the fabrication of asymmetric free-standing layer-by-layer film with asymmetric wettability – one surface is superhydrophobic and the other one is hydrophilic. The superhydrophobic side is water-repellent while the hydrophilic side can absorb/desorb water easily. | |

| As the researchers report in a recent edition of Applied Materials & Interfaces ("Asymmetric Free-Standing Film with Multifunctional Anti-Bacterial and Self-Cleaning Properties"), the superhydrophobic surface was proved to to be self-cleaning, anti-wetting and to limit bacterial adhesion, while the hydrophilic surface could extensively deliver bactericidal silver ions. | |

|

|

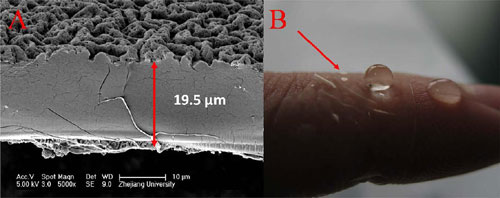

| (A) SEM image of the cross-section of free-standing (PEI-Ag/PAA)20 film. (B) Digital photo of a free-standing (PEI-Ag/PAA)20 film deposited on skin of finger. The top surface is superhydrophobic and the film is transparent. (Reprinted with permission from American Chemical Society) | |

| The team, led by Catherine Picart, a professor at Grenoble INP in France, and Jian Ji, a professor in the Department of Polymer Science Engineering at Zhejiang University in China, used an amplified LbL method to prepare a film of up to 20 micron thickness. When released from its substrate, this free-standing asymmetric membrane had one surface rough and superhydrophobic and the other surface flat and hydrophilic. | |

| In previous work, the team already reported the stimuli responsiveness of their asymmetric free-standing film ("Humidity Responsive Asymmetric Free-Standing Multilayered Film"). In this new work, they have now added additional functionality to the superhydrophobic/hydrophilic asymmetric film. | |

| They loaded the film with silver nanoparticles which resulted in the hydrophilic surface becoming bactericidal by extensively releasing silver ions. Importantly, the film can be transferred to another interface, such as human skin. | |

| "The superhydrophobic/hydrophilic asymmetric film may find application in wound healing" Ji tells Nanowerk. "Imagine a medical dressing where the superhydrophobic surface on top protects the wound from dust and bacteria while the hydrophilic surface at the bottom delivers drugs that can accelerate wound healing or help avoid infections." | |

| He adds that the excellent anti-adhesion ability of the top surface stems from a combination of micro-nano hierarchical structure and superhydrophobicity – which leads to anti bacteria adhesion. "Of note" he says, "the size of microstructure on the film here was about 2-5 µm, close to the size of E. coli." | |

| One issue the scientists note is that this film is flexible in wet environments but brittle in a dry state. One solution would be to reinforce the film by introducing nanoparticles, such as nano clay, into the multilayer film. | |

| Overall, this concept of asymmetrically functionalizing multilayer free-standing films may open a new avenue for the layer-by-layer technique. Apart from wound dressings, asymmetric, multifunctional films may be of great potential for use in the area of barrier, separation, transportation or drug delivery. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|