| Posted: Mar 08, 2013 | |

We can grow graphene. But graphene oxide? |

|

| (Nanowerk Spotlight) Unlike silicon, graphene lacks an electronic band gap – the gap being an energy range that cannot be occupied by electrons – and therefore has no switching capability; which is essential for electronics applications. Opening an energy gap in graphene's electron energy spectrum is therefore a critical prerequisite for instance for creating graphene transistors. | |

| Researchers have developed various post-processing approaches of graphene to open the band-gap – strain engineering (read more: "New approach to strain engineering graphene circumvents current methods' limitations"), lateral confinement, breaking inversion symmetry in bilayer graphene, and oxidation. | |

| Another method of obtaining a bandgap is to use reduced graphene oxide (RGO). Despite its advantages – inexpensive material with an industrial-scalable production route – the main problem that prevents the use of graphene oxide in electronics is the high electrical conductivity deviation between fabricated chips. | |

| Researchers from Nanyang Technological University (NTU) in Singapore, led by Alfred Tok, Associate Professor and Deputy Director of the Institute for Sports Research, and Dr. Christoph Nowak, Biosensors Technologies business unit of the Austrian Institute of Technology (AIT) & Centre for Biomimetic Sensor Science in NTU (CBSS); partnering Dr. Melanie Larisika, Biosensors Technologies (AIT) & (CBSS); and in collaboration with Prof. Myra A. Nimmo, School of Sport, Exercise and Health Sciences (SSEHS) of Loughborough University (LU), have now managed to grow and extend graphene oxide out of graphene oxide flake templates. This growth helps to reduce the electrical conductivity standard deviation by an impressive 80%. | |

| The study, recently reported in Nanoscale ("The extended growth of graphene oxide flakes using ethanol CVD"), uses atmospheric-pressure ethanol chemical vapor deposition (CVD) with hydrogen and argon gas. With a treatment of just 2 hours, the silicon dioxide substrate was fully covered with few-layer reduced graphene oxide from an initial coverage of 65%. | |

| This is the first example of successful growth of reduced graphene oxide using graphene oxide template. | |

|

|

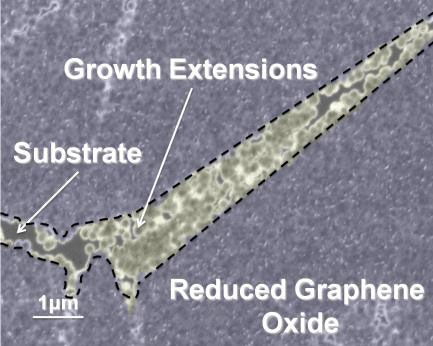

| High Resolution Scanning Electron Microscopy Image (HR-SEM) showing the reduced graphene oxide growth extensions bridging between two existing Reduced Graphene Oxide flakes. (Image: Jingfeng Huang) | |

| "Inspired by the growth process of carbon nanotubes, the growth of graphene oxide follows the use of hydrogen gas to remove any amorphous carbon and to help etch away the oxygen groups at the edges of the graphene oxide, therefore facilitating the deposition of new carbon atoms," Jingfeng Huang, a researcher at the School of Materials Science and Engineering, and the paper's first author, tells Nanowerk. "By using graphene oxide as the template, the observed new growth is also found to be graphene oxide." | |

| The researchers say that, in principle, the size of the reduced graphene oxide sheet that can be grown is only limited by the size of the tube furnace and base substrate. | |

| "We managed to solve a teething problem with existing graphene oxide based bio-sensors and electronics: the poor homogeneity of electrical resistance between fabricated chips," says Qiyuan He, a research fellow at University of California, Los Angeles, and a co-author of the paper. "Our preliminary results help pave a way for increasing the usage of the aqueous-processable and low-cost graphene oxide in these areas." | |

| A new, unpublished study by Tok and his team reveals that the CVD-grown graphene oxide chips can be used for ultra-sensitive molecular sensing. | |

| "In future, we can use this growth technique to create mass-producible practical graphene oxide based bio-sensors and electronics," says Tok. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|