| Posted: Jun 24, 2013 | |

3D nanolithography without the expensive hardware |

|

| (Nanowerk Spotlight) Nanolithography has traditionally involved very expensive processes and the cost of advanced lithography tools, mask making, complex process and relevant materials has become a serious economic concern for the semiconductor industry. Today, the cost to build state-of-the-art facilities to manufacture computer chips runs into the billions of dollars. | |

| While researchers are working on developing more cost-effective nanolithographic tools such as for instance superlens lithography, one of the key problems with nanofabrication is how to generate ever-challenging patterns with high resolution – especially for 3D nanostructures – and at the same time substantially reduce the cost of the process. | |

| "Among the diverse emerging nanofabrication methods, colloidal-based technique has also drawn wide attention" Chih-Hao Chang, an Assistant Professor in the Department of Mechanical and Aerospace Engineering at North Carolina State University (NCSU) explains to Nanowerk. These 'bottom-up' techniques exploit colloidal particles as elementary building blocks, where the particles self-assemble to form 3D structures or act as physical masks for subsequent additive deposition or subtractive etching. These techniques can yield high-quality nanostructures, such as hemispherical metal caps, nanopores, and sculptured colloids with relatively low costs." | |

| In previous work in 2011, Chang's group demonstrated that close-packed colloidal arrays can also be used as an optical phase mask to fabricate periodic 3D nanostructures with controllable lattice parameters ("From Two-Dimensional Colloidal Self-Assembly to Three-Dimensional Nanolithography"). | |

|

|

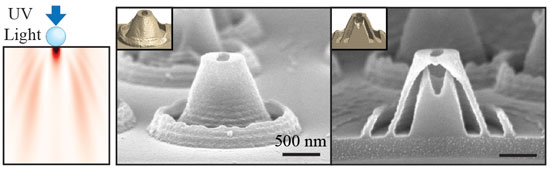

| A single colloidal sphere is illuminated to create a scattering pattern, which is captured by a photoresist in close proximity. No external optical elements are required, and the colloidal elements alone provide the modulation of the optical intensity pattern. The fabricated nanostructures can be designed to have multiple shells, confined volumes, and single top openings, resembling 'nano-volcanoes'. The geometry of such structures is dependent on the scattered light distribution and can be accurately modeled by examining the light–particle interaction. (Reprinted with permission from American Chemical Society) | |

| Now, in new work published in the June 5, 2013, online edition of ACS NANO ("Three-Dimensional Nanolithography Using Light Scattering from Colloidal Particles"), the NCSU team developed a new nanolithography method based on light scattering from nanoparticles, which can generate 3D hollow-core structures that resembles 'nano-volcanoes'. | |

| Different from traditional lithography methods that are typically based on complex systems, this process relies solely on the light interaction with a single nanoparticle. No masks and external optics are needed in this approach, and light is manipulated into the desired optical pattern solely by the colloids. The colloidal elements are assembled directly on the photoresist. And since this approach requires no system hardware, it is extremely low cost. | |

| According to Chang, the most important contribution of this work is to present a fundamentally different approach to 3D lithography. "We were wondering if it is possible to do some 'lithography' with colloidal particles, which can be batch synthesized thanks to the rapid advances made by chemists and material scientists," he says. "Our solution is to take a well-understood physical process of light scattering by particles, which is important in other areas such as describing optical phenomenon in atmospheric science, and use it for nanolithography. Through this simple framework we are able to design 'nano-volcanoes' with various geometries." | |

| In their novel nanolithographic process, the researchers create the volcano-shaped nanostructures by placing spherical, transparent polymer nanoparticles directly onto the flat surface of a thin film. They then shine ultraviolet light through the transparent sphere, which scatters the light and creates a pattern on the thin film. The thin film is made of a photoreactive material that undergoes a chemical change wherever it has been struck by the light. The researchers then submerge the thin film in a liquid solution that washes away the parts of the film that were exposed to light. The material that remains is shaped like a nanoscale volcano. | |

| "We can control the pattern of light by changing the diameter of the nanoparticle spheres, or by changing the wavelength – or color – of the light that we shine through the spheres," says Xu Zhang, a PhD student in Chang's group and lead author of the paper. "That means we can control the shape and geometry of these structures, such as how big the cavity of the nano-volcano will be." | |

|

|

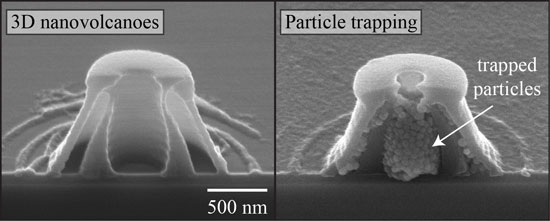

| Left: an empty double-shelled nano-volcano. Right: 50 nm diameter silica nanoparticles trapped inside a nano-volcano. (Image. Dr. Chang, North Carolina State University) | |

| One application for these 'nano-volcanoes' is to trap nanoparticles. Since the volume and opening of these nanostructures can be controlled during the fabrication process, they potentially could be used as a drug delivery system in a patch-like platform. This is one area that Chang and his team currently are working on. For instance, the team is working to improve its understanding of the release rate from the nano-volcanoes, such as how quickly nanoparticles of different sizes will 'escape' from nano-volcanoes with different-sized openings. | |

| "That’s essential information for drug-delivery applications," says Chang. | |

| Another area is the shape of the fabricated nanostructures. Since this work focused on readily available spherical nanoparticles as scattering objects, other types of colloidal elements, such as cubic, tetrahedral, and rod particles, can be incorporated into this approach to enable a wide variety of achievable 3D nanostructures. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|