| Posted: Aug 06, 2013 | |

Novel CNT-copper nanocomposite delivers a 100-fold increase in current density |

|

| (Nanowerk Spotlight) With the semiconductor industry still on the path of Moore's law, researchers have already been toying with single-molecule electronics (read more: "Single-molecule nanoelectronics is getting closer to reality") and molecular memory (see: "Storing data in individual molecules") to push miniaturization of electronics to its limit. | |

| However, with electrical gadgets and devices getting increasingly smaller and functionally more powerful, the current density flowing through the copper and gold conductors in these devices – which supply power to transistors, switches and memory – has been exponentially increasing. | |

| "Currently, technologically, we are at the limits of what copper and gold can deliver in terms of current density and electrical conductivity," Chandramouli Subramaniam, a researcher at the Super Growth CNT - Nanotube Research Center at AIST in Japan, tells Nanowerk. "Therefore, electrical conductors with higher current density tolerance (or current carrying capacity) are in huge demand. Our recent research was motivated to address this demand." | |

| Subramaniam and his colleagues, together with collaborators from the Technology Research Association for Single Wall Carbon Nanotubes, have now developed a carbon nanotube-copper (CNT-Cu) nanocomposite material that overcomes the mutual exclusivity of high ampacity and high conductivity – the former requires a strongly bonded system, whereas the latter requires the free electrons from a weakly bonded system – by effectively combining the strengths of copper (high electrical conductivity) and CNTs (high current density tolerance) into one integrated composite material. | |

| Reporting their findings in the July 23, 2013 online edition of Nature Communications ("One hundred fold increase in current carrying capacity in a carbon nanotube–copper composite"), the team demonstrated that the ampacity of their CNT-Cu composite (at 630 x 106 A cm-2) is 100 times higher than common electrical conductors, such as copper and gold, approaching the theoretical limit for CNTs (1000 x 106 A cm-2). | |

|

|

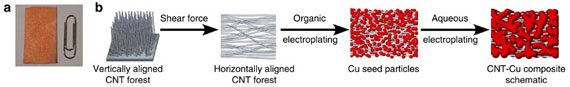

| (a) Picture of CNT–Cu composite alongside a paperclip for size reference. (b) Schematic representation of various steps for CNT–Cu composite fabrication. Cu seeds nucleate on the CNT surface during the organic electrodeposition and subsequently grow during the aqueous electrodeposition to yield the CNT–Cu composite. (© Nature Publishing Group) (click image to enlarge) | |

| "We discovered that the presence of carbon nanotubes leads to the suppression of atomic electromigration of copper," explains Subramaniam. "Suppressing the mass-diffusion of copper – under the influence of electric field – provides our CNT-Cu composite material with a high degree of tolerance to current density. Thus, CNT-Cu is able to withstand and transport over 100 times higher current density compared to metals such as copper, gold and silver." | |

| Importantly, the researchers were able to achieve this high current density tolerance without sacrificing the electrical conductivity of the material, which is similar to that of pure copper. | |

| "This is the first such material, to the best of my knowledge, that can have high electrical conductivity and high current density tolerance," Subramaniam points out. "I consider this to be a huge advancement in the field of electrical power transmission, ranging from interconnects and vias – in integrated chips and microelectronic devices – to high power transmission." | |

| To fabricate their CNT–Cu composite, the team developed a unique fabrication process. In contrast to conventional approaches that use CNT–Cu ion dispersions, they electrodeposited copper into the pores of premade, macroscopic CNT structures such as buckypaper and closely packed CNT forests. The result is a composite where the CNT cover the surfaces and grain boundaries of polycrystalline copper. | |

| This CNT-Cu material with high current carrying capacity is likely to find applications in all areas where high ampacity, low density electrical conductors are required. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|