| Posted: May 08, 2014 | |

New method to evaluate the exfoliation and fragmentation results of 2D materials |

|

| (Nanowerk Spotlight) Scientific journals are inundated with graphene-related papers from research groups around the world. Every week, dozens of new publications claim new findings relating to graphene applications or fabrication techniques. | |

| There are already several technologies that potentially allow mass production of graphene sheets (read more: "Mass production of high quality graphene: An analysis of worldwide patents") – by chemical vapor deposition growth; by epitaxial growth of graphene on top of a metal surface; and various wet chemical processes of processing graphene in solution by exfoliating graphite. | |

| However, as Konstantinos Kouroupis-Agalou, a PhD/Marie Curie Fellow at the Istituto per la Sintesi Organica e la Fotoreattività-Consiglio Nazionale delle Ricerche (ISOF-CNR), in Bologna, Italy, tells Nanowerk, the way these 2D sheets are produced in solution, by exfoliation, is an original process, still not completely understood. | |

| "The exfoliation of a 2D object from a 3D bulk material is a process spanning from the nano- to meso-scale due to bubble cavitation, intercalation and disruptive fragmentation," he explains. "Exfoliation always yields a polydispersed range of nanosheet thickness and lateral size. When characterizing these 2D sheet solutions, their average size and size standard deviation are commonly reported, often assuming that their size follows a 'Gaussian' – i.e. 'normal' – distribution. Conversely, the experimental data show that the size distribution of these materials is highly asymmetric and non-Gaussian." | |

| This situation creates a strong need for methods to evaluate the exfoliation of 2D materials, and to better understand how these materials are produced at nanoscale level. A new paper published in Nanoscale ("Fragmentation and exfoliation of 2-dimensional materials: a statistical approach"), first-authored by Kouroupis-Agalou, touches upon an interesting fundamental question: what is the intrinsic shape and size distribution of 2D nanomaterials? | |

| The core of this work, led by Palermo Vincenzo, head of research unit 'Functional Organic Materials for High-Tech applications' and group leader of the Nanochemistry Lab at ISOF, and Nicola Pugno, Professor of Solid and Structural Mechanics at the University of Trento, is based on the need to evaluate and quantify the quality of processed 2D nanomaterials with a characterization technique that is commonly used in science and industry – Atomic Force Microscopy (AFM). | |

|

|

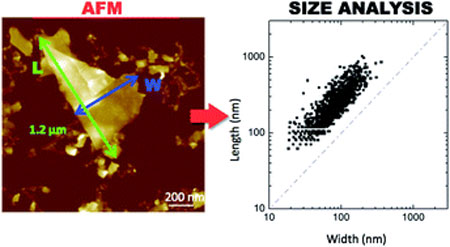

| Left: Zoom-in of a single nanosheet, showing the typical way to define and thus estimate its length and width. Right: Length/width plots of BN sheets measured in the case of high power sonication. (Image: Konstantinos Kouroupis-Agalou, ISOF-CNR) | |

| Using automatized image processing of AFM data to measure, one by one, the exact shape and size of more than 6000 nanosheets obtained by exfoliation of an important 2D-material, boron nitride, the team employed different statistical functions to model the asymmetric distribution of nanosheet sizes typically obtained. They found that the exfoliation of 2D nanomaterials, like the distributions recognized in the fields of biology, astronomy and mineralogy, follows Poisson statistics, rather than the symmetric Gaussian distribution. | |

| "The size distribution of the sheets at a given time follows a log-normal distribution, indicating that the exfoliation process has a 'typical' scale length that changes with time and that exfoliation proceeds through the formation of a distribution of random cracks that follow Poisson statistics," says Kouroupis-Agalou. "The validity of our model implies that the size distribution does not depend on the different preparation methods used, but is a common feature in the exfoliation of this material and thus for other 2D materials." | |

| The results presented in this work provides materials scientists working with graphene and other 2D materials an analytical method with which to control, quantify and evaluate the exfoliation results of nanomaterials that are produced through the most well-known methods of liquid phase exfoliation and ball milling. | |

| This method – correlating the size distribution of the exfoliated materials with the physical aspects of the fragmentation mechanism – allows for a better understanding of how these materials are produced at a nanoscale level, paving the way to the process control of composite materials production. | |

| The fragmentation and exfoliation mechanism effect on 2D materials is still a new area to be explored. As the researchers point out, there is still a need for an in-depth understanding of this mechanism by studying the physics and the engineering of the exfoliation process and correlating it with the improvement of the exfoliation results for 2D materials beyond graphene. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|