| Posted: Jan 27, 2015 | |

Nanowaste - Nanomaterial-containing products at the end of their life cycle (page 2 of 4) |

|

| Nanomaterials in waste streams | |

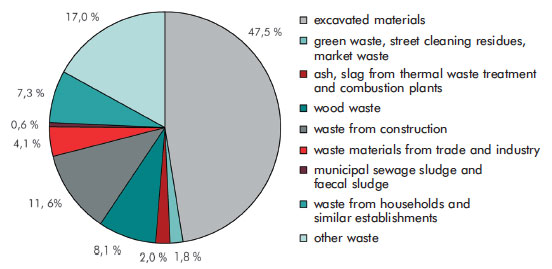

| Austria generates more than 50 million tons of waste per year. Materials that arise from digging or excavating the soil or subsoil make up the largest proportion (Fig. 2). Such excavated material could be contaminated with nanomaterials via several pathways, for example through nanomaterial-containing building materials. No studies are available on this issue. Ash and slag from thermal waste treatment plants can also contain nanomaterials, as can construction wastes (see further below) or household wastes. In principle, nanomaterials can be present in all waste categories. | |

|

|

| Figure 2: Percentages of selected waste categories in 2010 (Basis: 51.72 million tons).9 | |

| “Nanowaste” can already arise in ENM production and use by industry and trade, for example in the form of faulty batches, production wastes, filter residues, of wiping cloths or solvents contaminated with nanoparticles, but also as residues produced by research and development facilities. | |

| According to a working group commissioned by the Swiss Bundesamt für Umwelt (BAFU; Federal Department of the Environment), companies that produce or process synthetic nanomaterials should in particular take the following measures in dealing with “nano-wastes”:10 | |

|

|

|

| Currently, too little is known about the behavior of ENMs in waste incineration plants. This leads to the recommendation not to dispose large quantities of nanowastes from indus try and trade in such facilities.10 This, however, raises the question of viable alternatives, such as chemo-physical treatment methods. | |

| The special application of ENMs in industrial processes (e.g. filter or catalyst technologies) enables ENMs to be collected in unmixed form. Their use in consumer products such as cosmetics, textiles, paints and varnishes, etc., however, leads to a diffuse distribution. This considerably complicates separate collection.3 | |

| Waste treatment in Austria | |

| The European Waste Framework Directive11, which has been implemented in the Austrian Waste Management Act (AWG 2002)12, is based on the following hierarchy: | |

|

|

|

| In Austria the targeted recycling of separately collected waste fractions (paper, metals, plastics, glass) from municipal wastes is well established.13 In 2009, 63% of the wastes were collected for processing and recycling. | |

| The residual waste (from households and similar institutions) undergoes either mechanical-biological waste treatment (24.4%; basis 2009) or thermal waste treatment in incineration plants (70.5%; basis 2009).14 | |

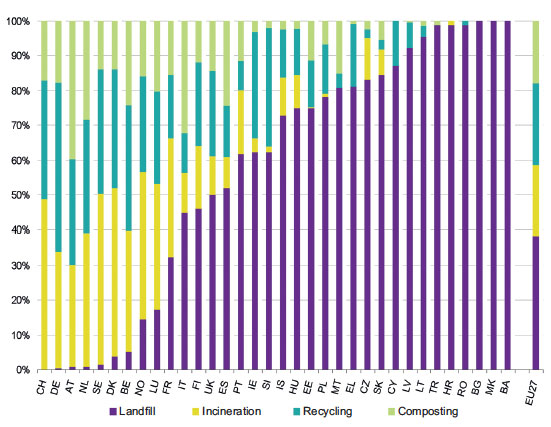

| In Austria the wastes must be pre-treated or recycled, and only very small amounts are directly disposed. The residues from the waste treatment plants (e.g. slag after incineration) as well as construction and demolition waste are dumped. In many other EU countries, however, municipal wastes are largely or entirely disposed in landfills without pre-treatment (Fig. 3.). | |

|

|

| Figure 3: Municipal wastes according to treatment categories – inner-EU comparison.15 | |

| Many products that are re-used in recycling processes (for example electrical and electronic equipment, metals, plastics, paper, cloth ing, etc.) can contain nanomaterials and these can potentially be released. At least four different processes could lead to releases during recycling:16 | |

|

|

|

| Experts from the “Hans Böckler Stiftung” of the Deutschen Gewerkschaftsbundes (German Trade Union Federation) therefore made an important recommendation in their working paper on the significance of nanomaterials in waste recycling16: future research efforts on the risk potentials of nanomaterials should be devoted to treatment processes for potentially nanomaterial-containing consumer products. The individual material streams in the recycling chains should be examined in detail regarding the types and amounts of nanomaterials being used. This would help estimate the degree of potential risks. | |

| Continue to next page (3 of 4) | |

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|