| Posted: Apr 04, 2006 | |

Carbon/copper nanocomposites as novel, low-cost sensor materials |

|

| (Nanowerk News) Researchers in Switzerland succeeded in the large-scale production of carbon-coated copper nanoparticles. These carbon/copper nanocomposites could be used as novel, low-cost sensor materials and offer a metal-based alternative to the currently used brittle oxidic spinels or perovskites. | |

| Their optical, catalytic, mechanical and electrical properties make copper nanoparticles a promising subject for research leading to new applications and devices such as lubricants, sensors, or catalysts. If the application requires the copper nanoparticles to be protected from oxidation, the copper nanostructures are usually encapsulated in organic or inorganic material such as carbon, silica or polyethylene. | |

| For any application to be commercially viable low-cost and large-scale production methods have to be developed. The Swiss researchers decided to investigate the use of a flame spray-based process for the synthesis of carbon-protected copper nanoparticles since this method already is in use for the large-scale industrial production of oxides nanoparticles. | |

| "The use of reducing flame spray synthesis proved very effective for the large scale, one step preparation of carbon coated copper nanoparticles" Wendelin Stark from the Swiss Federal Institute of Technology (ETH) in Zurich told Nanowerk. | |

| Stark is Assistant Professor of Catalysis at the Institute for Chemical and Bioengineering at ETH. Together with Evagelos Athanassiou and Robert Grass he published his recent findings, titled "Large-scale production of carbon-coated copper nanoparticles for sensor applications" in the March 28, 2006 edition of Nanotechnology. | |

|

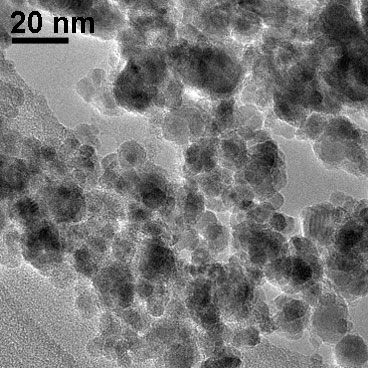

Electron microscope image of carbon-coated copper nanoparticles produced by flame spray synthesis under highly reducing conditions. (Source: ETH Zurich) |

| The researchers were able to use their experimental set-up for the continuous large-scale production (10–100 g samples) of carbon-coated copper nanoparticles. Instead of forming copper oxide as in conventional flame spray synthesis, the highly reducing conditions resulted in the formation of zero-valent copper particles. | |

| "In contrast to earlier studies that provided materials consisting predominantly of carbon, the use of reducing flame spray synthesis allowed the preparation of only 1 nm thin carbon layers on copper nanoparticles" Stark says. The so encapsulated copper nanoparticles were stable in air. | |

| "The specific geometry of the C/Cu nanoparticles provided highly temperature and pressure sensitive conductivity which was at least comparable or superior to currently used, oxide-based spinels or perovskites" Stark concluded. These nanoparticles may therefore offer an alternative sensor material for temperature and pressure sensing. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.