| Posted: Mar 12, 2008 | |

Protecting nanotechnology workers |

|

| (Nanowerk Spotlight) Notwithstanding the mixed news (to put it mildly) that individual investors have been getting from their nanotechnology stock portfolios, industry as a whole is pressing ahead with incorporating nanotechnologies in their products and processes. Unlike many other areas of science, nanosciences are capable of influencing a wide sweep of industrial and medical processes, from cleaner energy applications, to smart materials and revolutionary medical applications. It is increasingly difficult to know which products use nanotechnology or incorporate nanomaterials; nanotechnology consumer product directories give an idea where nanomaterials are used but are increasingly useless in helping to understand the full extent of nanotechnologies penetrating industrial manufacturing processes. | |

| Some consumer companies embrace 'nano' wholeheartedly and advertise their 'revolutionary' face creams, tennis rackets and car waxes; some, after increased scrutiny, have become very quiet about their nanotechnology activities (especially the large cosmetics and food companies); and some even change their company name to something that doesn't include 'nano' ('cleantech' or 'greentech' has become the new nanotech). Combine this technological shift that is taking place in industries across the board with the still existing lack of conclusive answers about the toxicity of nanomaterials, and you get a worrisome mix of industry pushing ahead unconstrained, a regulatory environment where key constituencies are ill prepared and underfunded to address the issues with the speed required, and public opinion that covers the whole range from activists calling for a complete moratorium on all things nano to snake-oil salesmen who promise nanotechnology stock tips that will make you a gazillionaire. Oh, and apparently now you can also add to this mix certain religious types in the U.S. who find nanotechnology is morally not acceptable. | |

| This leaves industry workers who potentially are exposed to nanoparticles in their workplace between a rock and a hard place: their companies are at the leading edge of industry, shifting to nanotechnologies in their manufacturing processes to gain competitiveness and create tomorrow's high-tech jobs. On the other hand, even with the best intentions from their employers, there are no sufficient guidelines, regulations or best practices that ensure sufficient worker protection. The problem is that it is very hard to protect against a risk that is neither clearly defined nor understood. | |

| Many companies that want to take active steps in implementing safety protocols to assure their workers' safety have almost nowhere to turn. We wrote about this problem, and what companies pro-actively are doing about it, in a previous Spotlight (Collaboration is key to protecting nanotechnology workers) where we highlight the specific steps that three proactive companies (Altairnano, QuantumSphere, QD Vision) are undertaking to assure their employees' safety. | |

| Some government agencies, like for instance NIOSH (National Institute for Occupational Safety and Health) in the U.S. are taking an active stance in helping industry to address potential safety concerns by exchanging information among companies about best practices and safety guidelines for nanomaterials. Other countries that are very active in nanotechnology have similar initiatives, but many countries don't. | |

| A recent survey that was published in Environmental Science & Technology exemplifies the issue: The authors, Kaspar Schmid and Michael Riediker from the Institute for Work and Health at the University of Lausanne in Switzerland, evaluated the use of nanoparticles, the currently implemented safety measures, and the number of potentially exposed workers in all types of industry in Switzerland (Use of Nanoparticles in Swiss Industry: A Targeted Survey). | |

| Although this study was limited to Switzerland, and it is not entirely representative as it was targeted to certain sectors, it stands to reason that its findings are indicative of the current state of nanoparticle use and safety 'best practices' across industries and countries. | |

| The survey showed that nanoparticles are already used in many industrial sectors; not only in companies in the field of nanotechnology, but also in more traditional sectors, such as paints. Schmid and Riediker write that "Forty-three companies declared to use or produce nanoparticles, and 11 imported and traded with prepackaged goods that contain nanoparticles. The median reported quantity of handled nanoparticles was 100 kg/year but the distribution ranged from 'several grams' to 1000 tons. The production of cosmetics, food, paints, powders,and the treatment of surfaces used the largest quantities of these nanoparticles. Generally, the safety measures were found to be higher in powder-based than in liquid-based applications." | |

| The key finding in this study was that the respondents had many open questions about best practices, which shows that regulators and industry bodies are badly lagging behind, and points to the need for rapid development of guidelines and protection strategies. | |

| The study identified 15 different types of nanoparticles in use in Swiss industry. Silicon dioxide and titanium dioxide were the two predominant nanoparticle-types. Eight other types of nanoparticles were used by only one company. Large-scale usages (several tons per year) were found for iron oxides, titanium dioxide, silver, aluminum oxide, zinc oxide, and carbon black nanoparticles. | |

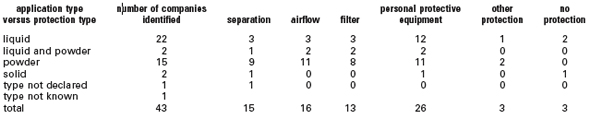

| The table below shows the protection measures used by the interviewed companies (the sum of the lines does not equal the number of the identified companies because several companies applied more than one protection type). | |

|

|

| Protection measures used for different application types as reported by interviewed companies (Reprinted with permission from American Chemical Society) | |

| The study notes that "most of the companies working with nanopowder used several types of protection-measures and many of those working with nanoliquids used only personal protective equipment. The following protection types were found: separation (the application of closed environments like closed machines or separated rooms); airflow (the use of a fume cupboard or a suction device); filter (the use of some form of air filtering system); and personal protective equipment (the use of masks, gloves, eyeglasses, etc.)." | |

| Few other protection types were indicated. All companies with nanoparticle-powders used protection measures, most of them used several types of protection. Seven of the 22 companies with liquid-only applications provided only respiratory personal protective equipment. Two companies with a liquid and a solid application type did not use any protection at all. | |

| Another finding was that most of the protection measures seemed to have been conceived to be adapted to the perceived risk of the application type. For liquid or solid applications, most persons in charge assumed that nanoparticles would not become airborne. Consequently, they did not apply airways protection measures. | |

| Schmid and Riediker write that "almost all contacted safety managers answered our questions about nanoparticle applications and protection measures. Many of them gave detailed information about their EHS [Environmental Health and Safety] approach even though the predominant message was 'I am very interested in the topic of nanoparticles and EHS, but I don?t know enough'." | |

| What this study shows is that large-scale use of nanoparticles is already a reality in many industrial sectors. It also reaffirms the fact that there is not enough information available to corporate personnel dealing with nanotechnology EHS issues and what is available is not easily accessible, especially for smaller and mid-size companies. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.