| Posted: Jun 20, 2008 | |

Plastic motors driven by light only |

|

| (Nanowerk Spotlight) A fast-growing body of nanotechnology research is dedicated to nanoscale motors and molecular machinery. The results of these studies are spectacular: well-designed molecules or supramolecules show various movements upon exposure to various stimuli, such as molecular shuttles, molecular elevators and molecular motors. There are numerous Spotlights here on Nanowerk that cover this fascinating area, for example, just take a look at Nanotechnology reinvents the wheel or Catalytic nanotransporters for nanotechnology applications outside biological systems. | |

| So far, however, nobody has been able to directly observe the movements of these molecular machines and utilize the mechanical work done by them. Now, an international group of researchers have succeeded in amplifying the minuscule change in structures at a molecular level caused by an external stimulus (light) to a macroscopic change through a cooperative effect of liquid crystals. Using liquid-crystalline elastomers (LCEs) – unique materials having both properties of liquid crystals (LCs) and elastomers – the scientists have successfully developed new photomechanical devices, including the first light-driven plastic motor. In other words, with this novel material the energy from light can be directly converted into mechanical work without the aid of batteries, electric wires, or gears. | |

| "A motor device is one of the most useful energy conversion systems that can convert input energy directly into a continuous rotation" Dr. Tomiki Ikeda explains to Nanowerk. "Although chemomechanical motors and light-switchable molecular machines that can move objects by light have been demonstrated, light-driven plastic motors converting light energy directly into a rotation have not yet been realized." | |

| Ikeda, a Professor of Polymer Chemistry in the Chemical Resources Laboratory at Tokyo Institute of Technology, and his group focus on the fundamental understanding of the interaction between light and polymer materials from the viewpoint of innovative photonic applications, and create photofunctional polymer materials with precisely controlled molecular alignment. | |

| In their recent work, Ikeda's team in collaboration with Prof. Yanlei Yu's group at Fudan University in Shanghai and Prof. Christopher J. Barrett's group at McGill University in Montreal, have demonstrated new sophisticated motions of LCEs and their composite materials, which resulted in a plastic motor driven only by light. | |

| The team's findings have been published in the June 3, 2008 online edition of Angewandte Chemie International ("Photomobile Polymer Materials: Towards Light-Driven Plastic Motors"). | |

|

|

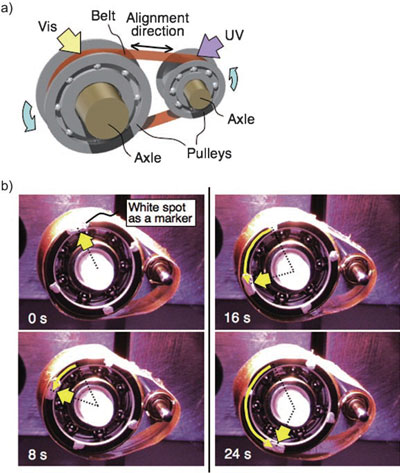

| A light-driven plastic motor with the LCE laminated film. a) Schematic illustration of a light-driven plastic motor system used in this study, showing the relationship between light irradiation positions and a rotation direction. b) Series of photographs showing time profiles of the rotation of the light-driven plastic motor with the LCE laminated film induced by simultaneous irradiation with UV (366 nm, 240 mWcm-2) and visible light (>500 nm, 120 mWcm-2) at room temperature. Diameter of pulleys: 10 mm (left), 3 mm (right). Size of the belt: 36 mm x 5.5 mm. Thickness of the layers of the belt: PE, 50 µm; LCE, 18 µm. (Reprinted with permission from Wiley-VCH Verlag) | |

| The researchers prepared a continuous ring of the LCE film (containing an azobenzene moiety) by connecting both ends of the film. Upon exposure to UV light from the downside right and visible light from the upside right simultaneously, the ring rolled intermittently toward the actinic light source, resulting almost in a 360 degree roll at room temperature. | |

| "This is the first example of this kind of photoinduced motion in a single layer film, although the rolling of the LCE ring used herein was slow, and stopped when the ring was broken by irradiation" says Ikeda. | |

| He describes a plausible mechanism of the rotation is as follows: "Upon exposure to UV light, a local contraction force is generated at the irradiated part of the belt near the right pulley along the alignment direction of the azobenzene mesogens, which is parallel to the long axis of the belt. This contraction force acts on the right pulley, leading it to rotate in the counterclockwise direction. At the same time, the irradiation with visible light produces a local expansion force at the irradiated part of the belt near the left pulley, causing a counterclockwise rotation of the left pulley. These contraction and expansion forces produced simultaneously at the different parts along the long axis of the belt give rise to the rotation of the pulleys and the belt with the same direction. The rotation then brings new parts of the belt to be exposed to UV and to visible light, which enables the motor system to rotate continuously." | |

| The size of the samples used in the experiments is in the range of millimeters, but is not in principle material-limited, so numerous applications even on the nanoscale are possible, especially where efficient power supply to mechanical system is battery-free and non-contact. These photomobile polymers function with a minimum of moving parts which minimizes the friction and surface contact difficulties that exist on a very small scale. | |

| Ikeda points out that various complex three-dimensional movements such as rolling and rotation of cross-linked liquid-crystalline polymers with azobenzene dyes can be induced upon irradiation with light. Light can be handled remotely, instantly and precisely, especially with lasers, and these plastic materials (photomobile materials) can work as main driving parts of light-driven actuators without the aid of any other external power source. | |

| "Few scientists believe that one could build mechanical systems only with organic materials like the ones that make up the human body" Ikeda says. "I believe that our work has demonstrated one possible way of building mechanical systems with organic materials. Ultimately, all-plastic cars driven solely by exposure to sunlight might be possible. They will have two sets of wheels covered with belts of photomobile polymer materials. By filtering the sunlight with plastic sheets, one can irradiate specific parts of the plastic belts with either UV or visible light to enable the plastic car to move. Today, this is just a dream. But one day it might become reality." | |

| Apart from the fact that photomobile materials don't require batteries, electric wires, or gears, another intriguing aspect of these polymers is that they can be controlled remotely just by manipulating the irradiation conditions. By controlling the area of irradiation, wavelength and the intensity of the light, one can drive a film or fiber made of these materials in a manner of choice, which enables them to be used as a wide range of photo actuators. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.