| Posted: Jul 14, 2006 | |

A new concept for compound nanotube fabrication |

|

| (Nanowerk Spotlight) A new method based on the nanoscale Kirkendall effect was demonstrated to fabricate compound nanotubes. Through a spinel-forming solid-state reaction, high aspect-ratio core-shell ZnO-Al2O3 nanowires transform into monocrystalline ZnAl2O4 nanotubes. | |

| Previously, compound nanotubes have been generated in various ways, for example, by rolling up layered materials, coating pores in templates, or by eliminating the core of a core–shell nanowire. In case of ternary (i.e. three element) compound nanotubes, however, most of these methods find limitations: either they need layered materials or templates (e.g., porous alumina), or the produced nanotubes have only small aspect-ratios and/or unacceptable crystallinity. | |

| In a recent article "Monocrystalline spinel nanotube fabrication based on the Kirkendall effect", published in the July 2, 2006 online edition of Nature Materials, the Zacharias group at the Max-Planck-Institute of Microstructure Physics (Germany) demonstrated a new concept for ternary compound nanotube fabrication using ZnAl2O4 spinel as an example. | |

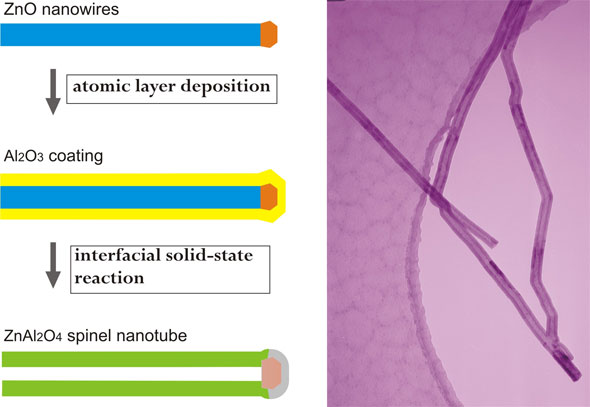

| We started with ZnO-Al2O3 core-shell nanowires. Single-crystalline ZnO nanowires (10-30 nm thick, up to 20 µm long) were first synthesized following the standard method in literature, and then coated with a 10 nm conformal layer of alumina through atomic layer deposition (ALD - see also a recent Nanowerk spotlight). The conformity and uniformity characteristics of ALD are essential to the formation of smooth nanotubes of the same lengths with the initial ZnO nanowires. | |

| Post-annealing the sample led to spinel-forming solid-state reaction between the core and shell, forming a ZnAl2O4 spinel interface. Stemming from the Kirkendall effect, the core material (ZnO) diffuses outward faster than the shell material (Al2O3) inward, effectively leaving vacancies behind. The vacancies aggregated into voids due to a spatial confinement by the shell. Finally tubular structure developed. | |

| |

| Transformation of ZnO nanowires to ZnAl2O4 spinel nanotubes through interfacial solid-state reaction involving the Kirkendall effect. Left: cartoon of the process. Right: TEM image of the spinel nanotubes. (Source: Max-Planck-Institute of Microstructure Physics) | |

| The advantage of this method over others includes: | |

| 1) it needs no porous templates like anodic alumina or layered materials, so that more complex and even 3-D nanostructures can be fabricated without extra effort; | |

| 2) the tubes have large aspect-ratios compared with tubes by other equally simple methods like etching core of core-shell nanowires; | |

| 3) it can be scaled up to produce volume quantities of nanotubes for applications, since a high-yield production of single-crystalline ZnO nanowires has become available world wide. | |

| The conceptual simplicity of this method might imply its generality and applicability to many other material systems based on the wealth information of their different reaction and diffusion properties known from well-studied thin film diffusion couples. Of course, such method is certainly not limited to ternary system, but workable to suitable binary systems like WSi2 and CdS through either solid-solid or solid-vapor reactions. Coming to limitation, in order to produce compound nanotubes, one must be able to fabricate first the core nanowires composed of the slower diffusion species. For example, Si nanowires for WSi2 nanotubes while Ni nanowires for Ni2Si silicide nanotubes. This may not be always an easy job. | |

| As a classical phenomenon in metallurgy, the Kirkendall effect had been also recently adopted to explain the formation of hollow spherical nanocrystals, first demonstrated by the Alivisatos group ("Formation of Hollow Nanocrystals Through the Nanoscale Kirkendall Effect"). It is believed that such effect should be generic and, given appropriate material selection, applicable to multi-dimensional systems. In this view, our result gives a strong proof-of-principle. | |

| Aside from the new concept for compound nanotube fabrication, our result simultaneously opens a window to produce spinel 1-D nanostructures. We also obtained volume quantity of MgAl2O4 spinel nanowires and nanotubes following a similar route. Prospectively, it becomes straightforward to fabricate many other types of ZnO and MgO-based spinel nanostructures according to the application necessity. From a fundamental research point of view, one question arises: how will the solid-state reactions on a curved nanoscale interface differ from those classical phenomena on planer interfaces or in powder forms? Same story or completely new? One difference we noticed is that necessary reaction temperatures are much lower, probably because of shorter diffusion path. We foresee it will be the time for the spinel community to shift their attentions. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.