| Posted: Oct 21, 2008 | |

Rolling up nanomembranes to build self-propelled microjets |

|

| (Nanowerk Spotlight) Nanoscale membranes are of great interest to researchers not only for nanofiltration applications but also in areas such as flexible electronics, extremely sensitive sensors, nanomedical applications and biomolecular research. Many of these applications would require the nanomembranes to be arranged in three-dimensional structures such as tubes, helices, rings, or wrinkles. | |

| So far, the roll-up of ultra-thin layers was heavily limited in materials choice, in most cases involving epitaxial semiconductor layers. The fabrication often requires a selective underetching procedure to release the nanomembranes from their substrate, a process which not only removes the underlying sacrificial layer but also in many cases dissolves the nanomembrane material itself. | |

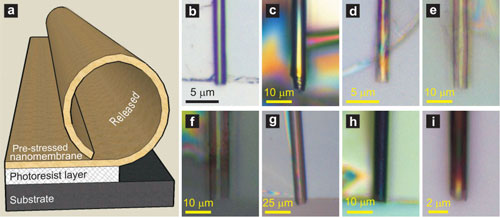

| A new approach developed by scientists in Germany and Hong Kong now allows controlled fabrication of pure metal and oxide tubes as well as many other material combinations. They describe a general method to produce well-defined micro- and nanotubes from thin solid films deposited by mass production tools. | |

| "We found that a huge variety of strained thin solid films, deposited on polymer sacrificial layers, can be released from a substrate as nanomembranes, spontaneously forming into micro-/nanotubes on basically any kind of substrate such as for instance glass or silicon" Dr. Yongfeng Mei tells Nanowerk. "Our approach provides a cheap way to engineer micro- and nanotubes out of many different materials and material combinations for easy integration on a single chip." | |

|

|

| a) Schematic diagram illustrating the roll-up process of a nanomembrane into a tube on photoresist; optical images of rolled-up nanomembranes made out of b) Pt, c) Pd/Fe/Pd, d) TiO2, e) ZnO, f) Al2O3, g) SixNy, h) SixNy/Ag, and i) DLC. (Reprinted with permission from Wiley) | |

| Mei, a researcher at the Institute for Integrative Nanosciences at the IFW Dresden, is the first author of a recent paper in Advanced Materials that describes this generic approach to engineer tubular micro- and nanostructures out of many different materials with tunable diameters and lengths by precisely releasing and rolling up functional nanomembranes on polymers ("Versatile Approach for Integrative and Functionalized Tubes by Strain Engineering of Nanomembranes on Polymers"). | |

| The team, which included scientists from the Max Planck Institute for Solid State Research and the Department of Physics and Materials Science at the City University of Hong Kong, points out that they can now fabricate pure metal and oxide micro- and nanotubes as well as almost any other solid state material. | |

| "Our technology spans across different scientific fields ranging from photonics to biophysics and we demonstrate optical ring resonators, magneto-fluidic sensors, remotely controlled microjets and two-dimensional confined channels for cell growth guiding" says Dr. Oliver G. Schmidt, who led the team. | |

| The novel approach works by depositing a pre-stressed inorganic nanomembrane at low temperatures onto a polymer sacrificial layer and then releasing it from the substrate surface by removing the sacrificial layer with a solvent, resulting in the membrane rolling up into a tube. | |

| Mei explains that choosing the right parameters for this process allows full control over tube diameters. He notes that the parameters are not fully decoupled from each other, and advanced strain engineering is required for every new material and material combination in non-epitaxial films. | |

| "First we exploit the difference in thermal expansion controlled by choosing appropriate deposition temperatures" he says. "It is well known that thermal stresses are caused by the difference in thermal expansion coefficients of deposited films and substrates. In order to enhance the stress gradient by the thermal expansion effect, we increase the substrate temperature for the initial part of the layer deposition." | |

| Mei explains that the second important deposition parameter, especially for evaporation or sputtering, is the deposition rate: " Different deposition rates may lead to different grain sizes in the layers, which in turn exert different stress levels in the nanomembrane. The tube diameter as a function of the film thickness agrees with the curve for a strain difference, which implies that the stress state is well-controllable by tuning the growth rate." | |

| "Finally, the relaxation and build-up of strain during deposition itself can lead to sufficiently large strain gradients to cause the roll-up process" says Mei. | |

| The researchers believe that the unique choice in materials and material combinations together with biocompatibility and accurate size, shape and geometry control might open additional objectives towards novel metamaterials and advanced bioanalytic microsystem. | |

| Mei and his colleagues are currently exploring their technology towards fast self-propelled microjet engines, possibly to deliver drugs at predefined locations. They point out that such synthetic micromachines can work autonomously, similar to biological micro-organisms converting chemical energy of a local environment into kinetic energy of their motions. | |

|

|

| Self-propelled microjet (Image: Dr. Mei/IFW Dresden) | |

| The team has fabricated a catalytic tubular microjet using a rolled-up titanium/iron/gold/silver multilayer nanomembrane. "Inside this microjet, hydrogen peroxide is decomposed into oxygen bubbles and water by a catalytic reaction of hydrogen peroxide with the inner silver tube wall" explains Mei. "The generation of bubbles, which are thrusted out at one of the openings, causes a highly directional and fast movement of the microjet." | |

| For nano objects, water becomes an extremely gooey substance. These microjets would be ideal vehicles to explore and ultimately copy the movements, acceleration and directional control of bacteria and viruses in fluids as well as the spatial and temporal investigation and control of individual cells on a chip. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.