| Posted: Sep 01, 2006 | |

Low temperature fabrication of CNTs for field emission displays |

|

| (Nanowerk Spotlight) Carbon nanotubes (CNTs) are considered the most promising material for field emitters and a practical example are CNTs as electron emitters for field emission displays (FED). | |

| CNT emitters are generally fabricated by indirect growth methods such as screen-printing and electrophoresis. These methods show advantages in lowering the coating temperature and scale-up of the substrate size, but the direction of CNTs cannot be well controlled and a post-treatment process is generally necessary to enhance the performance of CNT emitters. | |

| In contrast to the indirect method, chemical vapor deposition (CVD) is a common technique for growing nanotubes directly on the substrate with the assistance of metallic catalysts. With the CVD method, CNTs can be grown at desired locations with a specified direction. | |

| However,most synthesis technologies such as conventional thermal CVD or plasma enhanced CVD are performed at temperatures over 500°C, which may restrict the application of CNTs on plastic substrates. Therefore, lowering the growth temperature for CNTs is one of the important directions for facilitating CNT applications. | |

| Researchers in Taiwan demonstrated that CNTs can be synthesized on a cobalt coated silicon substrate using electron cyclotron chemical vapor deposition (ECR-CVD) and without intentionally heating the substrate. They fabricated vertical CNTs with microwave power as low as 300 W. | |

| The ability to grow CNTs at low temperatures allows CNT emitters to be synthesized on glass and plastic substrates. Direct fabrication of well aligned CNT emitters on normal glass is cost effective for manufacturing CNT-FED, while growth of CNTs on plastics makes flexible CNT-FED possible. Short CNTs on the other hand can be applied to nanoscale electronic devices such as nanowire field effect transistors (FET) and are suitable candidates for nano composite materials. | |

| Dr. Wen-Tuan Wu, Assistant Professor at the Department of Electro-Optical Engineering at Southern Taiwan University of Technology, explained the recent work: "We showed that the formation of CNTs on a cobalt-coated silicon wafer without intentional heating is possible using ECR-CVD in mixed gases of C3H8/N2. The morphologies of the carbon nanotubes are found to be mainly dependent on the microwave power and the C3H8/N2 flow rate ratio. The amount of nitrogen incorporated in the CNT films also considerably influences the structures of the CNTs." | |

| While the growth of carbon nanofibers and CNTs at a temperature as low as 120°C using plasma enhanced CVD has been reported already, these nanostructures are found to be defect rich. Further reducing the defects of CNTs in a low temperature process to enhance the field emission characteristics therefore has become a topic of interest for the application of CNTs in FED. | |

| A recent paper describing these findings ("Growth of carbon nanotubes on cobalt catalyst film using electron cyclotron resonance chemical vapor deposition without thermal heating"), first-authored by Wu, was published in the August 22, 2006 online edition of Nanotechnology. | |

| |

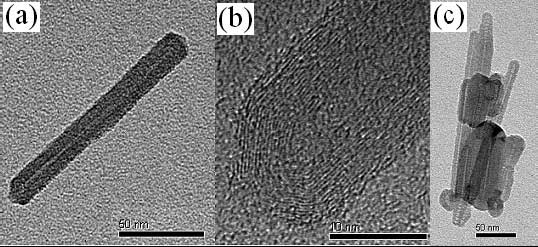

| FEG-TEM images of CNTs deposited on 3 nm thick Co catalyst film with C3H8/N2 = 20 sccm/20 sccm: at the ECR power of 300 W for 5 min. (a) The full CNT, (b) the closed-end tip, and (c) the bundle of CNTs. (reprinted with permission from the Institute of Physics Publishing) | |

| Wu and her colleagues observed three remarkable features of the CNTs they produced: (1) The length of the CNTs is only several hundred nm, which is much shorter than that (∼1.4 µm) for CNTs synthesized under the same process conditions except that the substrate temperature was set at 500°C. (2) It seems that the formation of N-doped CNTs without bamboo-like structure is possible at low temperatures although ECR-CVD is generally favorable for the formation of such a structure via the tip growth mode. (3) The bundle of CNTs exhibits both closed-end structures, and there are no catalytic particles found either at the tip or at the base of the CNTs. | |

| Wu notes that there are two issues that still need to be addressed: "The density of the short CNTs is still low and only multi-wall CNTs are obtainable. The density may be increased by elevating the substrate temperature, whereas single-wall CNTs may be fabricated using the other carbon gas sources." | |

| It has been well known that the catalyst metals provide a driving force to grow CNTs and they generally are left in the nanotubes. | |

| "In our findings" says Wu, "the catalyst metals do not appear in the tubes. This suggests that from a science point of view the formation of CNTs may be possible at low temperatures in the absence of catalyst metals. For our future work we might consider employing various ECR-CVD parameters, gas sources and substrate surface conditions to realize such an idea." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.