| Posted: Oct 27, 2008 | |

Brushing up on nanogenerators |

|

| (Nanowerk Spotlight) A major issue for using self-contained nanodevices, for instance as implantable nanosensors or environmental monitoring devices, is the question of how to power these tiny machines with an independent power source. Options include nanobatteries and nanogenerators that harvest energy from their environment. By converting mechanical energy from body movement, engine vibrations, or water or air flow into electricity, these nanoscale power plants could make possible a new class of self-powered medical devices, sensors and portable electronics. | |

| Probably the leading team that is driving forward the work on nanogenerators for converting mechanical energy into electricity is Zhong Lin Wang's group at Georgia Tech. We have covered their work before in articles about nanoscale power plants and nanopiezotronics. | |

| Wang's team has now designed and demonstrated an innovative approach to fabricating a nanogenerator by integrating nanowires and pyramid-shaped nanobrushes into a multilayer power generator. By demonstrating an effective way for raising the output current, voltage and power, this work provides the technological platform for scaling up the performance of nanogenerators to a level that some day might be able to independently power devices like pacemakers or iPods. | |

| "Our novel approach to building a nanogenerator is composed of integrated, paired nanobrushes made of pyramid-shaped metal-coated zinc oxide nanotip arrays and hexagonalprism-shaped zinc oxide nanowire arrays, which were synthesized using a chemical approach on the two surfaces of a common substrate, respectively" Wang explains to Nanowerk. "When one piece of this structure is stacked in close proximity over another to form a layer-by-layer matched brush architecture, direct current is generated by exciting the architecture using ultrasonic waves. A four-layer integrated nanogenerator is demonstrated to generate an output power density of 0.11 µW per square centimeter at a voltage of 62 mV." | |

| Wang points out that this design approach has several unique advantages: | |

| 1) One of the outstanding benefits of this approach is that the nanowires and nanotips do not have to be patterned on substrates in order to raise the output current/voltage, which greatly simplifies the fabrication process and cost. | |

| 2) The design does not demand that all of the nanowires and nanotips have a very uniform height and/or shape, thereby greatly reducing the complexity for sample growth. | |

| 3) The operation of the nanogenerator relies on mechanical deflection or bending of the nanowires, in which resonance of nanowires is not required to activate the generator. This largely expands their application from low frequency (in the hertz range) to a relatively high frequency (in the megahertz range) for effectively harvesting mechanical energies in our living environment. | |

| 4) The nanotips and nanowires were synthesized using a chemical approach at below 100°C. This simple and low-cost technology has an outstanding potential for large-scale application. | |

| 5) The layer-by-layer assembly technique that the scientists used provides a feasible technology for building multilayered nanogenerators for applications where force or pressure variation are available, such as a shoe pad, under skin layer for airplanes, and next to a vibration source such as car engine or tire. | |

| "Achieving an output voltage in the microwatt range, as we did, is good enough for powering nanodevices," says Wang. "In order to power larger devices such as MP3 music players we would need to be able to generate output in the 10-100 milliwatt range. Our novel nanogenerators demonstrate a scaleable platform for increased power output that would make this possible." | |

|

|

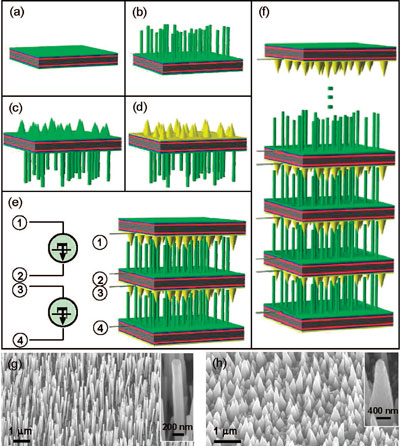

| Design and fabrication procedures of the multilayered nanogenerators and rational growth of zinc oxide nanowire and nanotip arrays. (a) The as fabricated substrate after coating with the zinc oxide seed layer. (b) Growth of hexagonal-prism-shaped nanowire arrays by wet chemical method on one side. (c) Growth of pyramid-shaped nanotip arrays on the other side. (d) Coating the nanotip arrays with an Au layer by magnetron plasma sputter. (e) Two-layered nanogenerator made by stacking three layers of the wafer structures shown in (d), with the Au-coated nanotip arrays facing and interpenetrating the bare nanowire arrays. The right-hand side is the designed symbol for representing the nanogenerators. (f) A multilayered three-dimensional nanogenerator integrated by stacking multiple layers of wafer structures. (g) 60° tilt view scanning electron microscopy (SEM) image of the hexagonal-prism-shaped zinc oxide nanowire arrays grown by chemical approach. (h) 60° tilted view SEM image of the pyramid-shaped zinc oxide nanotip arrays grown by chemical approach. Inset SEM images are high magnification views of a single nanowire and nanotip. (Reprinted with permission from American Chemical Society) | |

| To build their nanogenerators, Wang and his team fabricated zinc oxide arrays of controlled orientation and shape on a double-sided silicon wafer. By modifying the time and temperature parameters, they could control the morphology of the zinc oxide arrays. This way they grew nanowires on one side of the wafer and pyramid-shaped nanotips on the other. In a final step they coated the nanotips with a 100 nm thin gold layer in order to form a Schottky contact with the zinc oxide (here, the gold coating could be replaced with other metals to further reduce the cost of the process). | |

| "We then built our multi-layer nanogenerators by stacking together the pieces of the grown wafer structures where the gold-coated nanotips partially interpenetrate into the nanowires, much like an array of AFM tips" says Wang. " A great advantage of this design is that neither does it put a strict requirement on the height uniformity of the nanowires nor do we need to maintain a specific gap distance between the layers, thereby rendering it much easier to control the packaging of the layers." | |

| According to Wang, the energy conversion process can be understood from the change in local band structure induced by the piezoelectric potential, which is asymmetric across the nanowire with the stretched side positive and the compressed side negative. "When a nanotip slowly pushes a nanowire, a strain field is created across the nanowire width, with its outer surface in tensile and its inner surface in compressive strain. This asymmetric strain produces an asymmetric piezoelectric potential across its width. If the raise in local potential energy is large enough as determined by the degree of nanowire bending, the accumulated local n-type carriers in the nanowire can quickly flow through the contact into the nanotip, which creates a circular flow of the electrons in the external circuit, e.g., the output current." | |

| While in terms of a single nanotip/nanowire pair this process is transient, if you look at the statistical contributions from thousands of nanotip/nanowire pairs, this process is in a steady state, with a stable and continuous current output. | |

| An important role in this design is played by the Schottky barrier, which prevents the flow of electrons from the nanotip into the nanowire. This is a key structure for preserving the piezoelectric potential and releasing the free electrons from the nanowire into the nanotip. A working nanogenerator is required to have such a diode effect. | |

| Wang and his team are now working on improving the output voltage and energy storage after the generation. They believe that by increasing the size and number of layers they can further increase the output voltage. Once that voltage is high enough to operate an electronic device, such as a diode, the outputting electric energy from the nanogenerators can be stored for future use. | |

| This work has been published in the October 22, 2008 online edition of Nano Letters ("Integrated Multilayer Nanogenerator Fabricated Using Paired Nanotip-to-Nanowire Brushes"). | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.