| Posted: Sep 15, 2006 | |

Manufacturing multifunctional materials by surface design at the nanoscale |

|

| (Nanowerk Spotlight) New research coming out of France opens the route for the processing of numerous multifunctional materials with specific properties. So far, the design of new multifunctional devices based on the combination of different materials has been a real challenge in materials science. One way to develop multifunctional materials is the design of a surface at the nanometer scale. However, modifying the surface of materials by organizing nanoparticles of controlled size, morphology and amount of coverage into a uniform shell has proven to be a considerable hurdle. Numerous approaches are being developed for the synthesis of these materials using organic or inorganic coatings. French researchers used a coating process called supercritical fluid chemical deposition for nanomaterial surface design. | |

| Conventional methods for surface modifications such as chemical vapor deposition, atomic layer deposition or various solution-based approaches are not convenient for modifying surfaces of particles with different materials at the nanoscale. Rather, processes using supercritical fluids are an interesting alternative here. | |

| Dr. Cyril Aymonier from the Bordeaux Institute of Condensed Matter Chemistry explained the process to Nanowerk: "Supercritical fluid deposition (SFCD) is the most convenient of the supercritical fluid processes for the design of surfaces with inorganic nanoparticles. It consists of dissolving metallic precursors in a supercritical medium, generally CO2 (environmentally friendly, cheap, low critical coordinates ...), in which the particles to be coated are suspended. Metallic precursors with fluorous ligands such as hexafluoroacetylacetonates (M(hfac)x ) are mostly used owing to their high solubility in scCO2. These metallic precursors are chemically transformed to give the subsequent metal that deposits onto the surface of particles." | |

| As a way to obtain multifunctional nanomaterials, Aymonier and his colleagues report the controlled surface design of silica spheres, used as a model substrate, with copper nanoparticles (5–17 nm) with a tuneable amount of coverage (40–80%) at low temperatures without a catalyst (the presence of catalyst can be a problem regarding the final material properties). The findings are published in a paper, titled "Design at the nanometer scale of multifunctional materials using supercritical fluid chemical deposition", which appeared in the August 29, 2006 online edition of Nanotechnology. | |

|

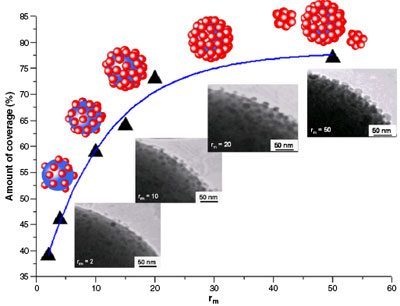

Evolution of the amount of coverage as a function of rm (the mass ratio of Cu(hfac)2·H2O/silica spheres) for copper nanoparticles of about 11 nm (Reprinted with permission from Institute of Physics Publishing) |

| "In our experiments, a homogeneous nucleation (one of the characteristics of the synthesis of nanomaterials in supercritical fluids) seems to be followed by heterogeneous growth of the copper nanoparticles at the surface of the silica spheres" says Aymonier. "Playing with nucleation and growth phenomena is a key point to control the formation of nanoparticles." | |

| This study demonstrates that the most important parameter for controlling the size of the copper nanoparticles is the temperature, due to kinetics aspects. Another key point for nanostructuring of the surface is the amount of coverage. The researchers have shown that the main parameter for tuning the amount of coverage of silica particles with copper nanoparticles is rm, the mass ratio Cu(hfac)2·H2O/silica spheres. | |

| Aymonier points out that, in addition to control of the size and amount of coverage, the reduction of copper precursor was performed at 100°C without any metal catalyst, what is very interesting for multifunctional material properties. 100°C is a low temperature when compared to results found in the literature of between 200 and 250°C for copper. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.