| Posted: Feb 23, 2009 | |

Evaluation of 'green' nanotechnology requires a full life cycle assessment |

|

| (Nanowerk Spotlight) As nanotechnology applications and nanomaterials slowly move into mainstream manufacturing, there will have to be an increasing focus on the environmental footprint that the production of various nanomaterials creates. A growing research body promises to lead to green(er) nanomanufacturing technologies (see: "Toward Greener Nanosynthesis" and the efforts of the University of Oregon's Safer Nanomaterials and Nanomanufacturing Initiative). | |

| However, as we discussed in our Nanowerk Spotlight "Nanotechnology - not that green?" last year, and to quote one of the conclusions from the paper above, "this emerging field of green nanoscience faces considerable research challenges to achieve the maximum performance and benefit from nanotechnology while minimizing the impact on human health and the environment". | |

| As it stands now, it remains to be seen what the environmental footprint of nanotechnologies will be. So far, the message is mixed. | |

| "Life cycle studies of emerging nanotechnologies are susceptible to huge uncertainties due to issues of data quality and the rapidly evolving nature of the production processes," Vikas Khanna tells Nanowerk. "With missing data about the large scale impact of nanotechnology, life cycle assessments of potential nanoproducts should form an integral part of nanotechnology research at early stages of decision making as it can help in the screening of different process alternatives." | |

| In a new study, Khanna, a Ph.D. candidate in the Process Systems Engineering Research Group in the Department of Chemical and Biomolecular Engineering Ohio State University (OSU) and Bhavik R. Bakshi, leader of the group, have compiled a life cycle inventory for carbon nanofiber (CNF) reinforced polymer nanocomposites (PNCs) based on available engineering information and published literature. | |

| Published in the February 11, 2009 online edition of Environmental Science & Technology (Carbon Nanofiber Polymer Composites: Evaluation of Life Cycle Energy Use), the two researchers evaluated and compared both thermoplastic and thermoset resin formulations with steel. They also compiled a case study involving the use of CNF-based PNCs in automotive body panels and compared this with a conventional alternative. | |

| "We focused on the life cycle energetic implications of carbon nanofiber reinforced polymer nanocomposite materials because these materials are attracting a lot of attention from the scientific community due to their multifunctional features such as mechanical strength, improved thermal and flame resistance, enhanced barrier properties, desirable level of electrical conductivity, and resistance to chemical attack," says Khanna. "Because of the combination of these properties, they are being considered as an attractive alternative to conventional materials such as steel and polypropylene". | |

|

|

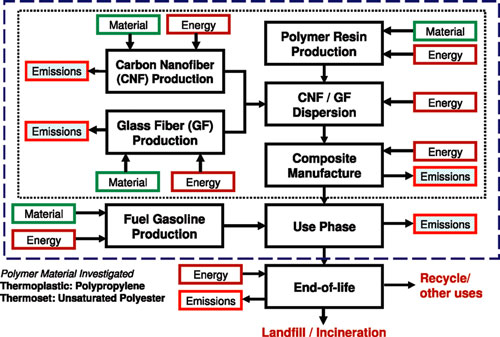

| Typical life cycle of polymer nanocomposite. Dotted lines indicate the system boundary for the cradle to gate comparison of PNCs with steel. Dashed lines represent the boundary for the automotive body panel case study. (Reprinted with permission from American Chemical Society) | |

| However, the research of the OSU team has demonstrated that on an equal strength (stiffness design) basis, CNF reinforced polymer composite materials are 1.6 - 12 times more energy intensive compared with steel for the range of CNF loading ratios investigated. | |

| While these numbers are quite worrisome, in the end the product use phase is more likely to govern whether the use of CNF reinforced PNCs will result in savings in net life cycle energy consumption. To that end, Bakshi and Khanna further evaluated the life cycle energetic implications of the use of these polymer composite materials in the body panels of automobiles as a potential replacement for steel. | |

| Khanna says that their findings indicate that the use of CNF reinforced PNCs in auto body panels has the potential for net life cycle fossil energy savings when compared with steel. These savings result from the improved fuel economy benefits during the use phase of the vehicle. | |

| This second part is crucial because, in essence, if applications of polymer nanocomposites do not save significant energy in their use phase, these nanoproducts may have a larger energy footprint than the conventional alternatives that they are supposed to replace. | |

| "There have been several international calls emphasizing the need for systems analysis of nanotechnology to understand both the potential benefits and risks posed by emerging nanotechnologies," says Bakshi. "Our work is a step in that direction and has contributed to addressing this need. It is the first life cycle energy analysis for the synthesis of CNF reinforced PNC materials. The data can be easily used to evaluate other product applications involving the use of CNF reinforced PNCs." | |

| Previous work by Bakshi and Khanna on the cradle-to-grave life cycle of CNFs ("Carbon Nanofiber Production) served as the basis for this study. They observed that, on an equal mass basis, CNFs are 13-50 times more energy intensive when compared with primary aluminum. | |

| Khanna points out that their research results highlight the hugely energy intensive nature of CNF synthesis. "Based on these findings we were further interested in comparing the environmental performance of specific nanoproducts based on CNFs as the quantity of use of engineered nanomaterials in consumer products may decide their energy and environmental impact". Which resulted in the present study. | |

| This kind of research is important as it highlights not only the benefits but also the potential risks associated with the large scale adoption of emerging nanotechnologies. Life cycle analysis of nanotechnology can also be used to identify phases in a product's life cycle with the maximum environmental impact and hence an opportunity for process or design modifications early in the product life cycle. | |

| This will be critical to ensure a safe and sustainable development of emerging nanoproducts. The huge challenge that researchers are faced with will be to compile a combined view of a nanomaterial's environmental life cycle footprint with regard to both energy use as well as its toxicological impact. So far, most of the required data does not exist or is proprietary to industrial companies. | |

| Many more efforts and resources have to go into the emerging field of green nanotechnology in order to enable a public dialog that is based on facts and serious research. Otherwise there is a chance that extreme viewpoints – "just a bunch of tree huggers trying to derail another promising technology" or "nanotechnology will kill us all" – will gain more prominence and there is no scientific basis to refute them. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|