Showing Spotlights 1249 - 1256 of 2779 in category All (newest first):

One item that so far has been missing from graphene's impressive list of physical properties is magnetism. In its pristine state, graphene exhibits no signs of the conventional magnetism usually associated with such materials as iron or nickel. So far, no reports that provide comprehensive evidence for either macro- or nanoscale magnetic phenomena for the ferromagnetism of carbon nanostructures in chemically functionalized graphene structures have appeared in the literature. Researchers have now filled this gap.

One item that so far has been missing from graphene's impressive list of physical properties is magnetism. In its pristine state, graphene exhibits no signs of the conventional magnetism usually associated with such materials as iron or nickel. So far, no reports that provide comprehensive evidence for either macro- or nanoscale magnetic phenomena for the ferromagnetism of carbon nanostructures in chemically functionalized graphene structures have appeared in the literature. Researchers have now filled this gap.

Nov 5th, 2013

Steerable nanodevices are envisioned for a multitude of applications. For example, magnetic nanodevices can be controlled via external magnetic fields. So far, scientist mainly have used costly synthetic routes to design and synthesize such devices. Now, though, a team of scientists has shown that a very simple route based on solution chemistry can also lead to such steerable machines. So far, most nano-and microscale propeller designs have been based on a biomimetic approach. The new approach is based on random aggregates.

Steerable nanodevices are envisioned for a multitude of applications. For example, magnetic nanodevices can be controlled via external magnetic fields. So far, scientist mainly have used costly synthetic routes to design and synthesize such devices. Now, though, a team of scientists has shown that a very simple route based on solution chemistry can also lead to such steerable machines. So far, most nano-and microscale propeller designs have been based on a biomimetic approach. The new approach is based on random aggregates.

Nov 4th, 2013

Material science is having a renewed influence on bioelectronics design beyond the incorporation of new functional nanomaterials. This newly established cooperation opens new windows for bioelectronics research, especially for fabricating flexible and smart devices. Recent advances in graphene research provide various possibilities to enhance performance characteristics and current approaches to design new bio-devices. Especially, smart and flexible bioelectronics on graphene has emerged as a new frontier in this area.

Material science is having a renewed influence on bioelectronics design beyond the incorporation of new functional nanomaterials. This newly established cooperation opens new windows for bioelectronics research, especially for fabricating flexible and smart devices. Recent advances in graphene research provide various possibilities to enhance performance characteristics and current approaches to design new bio-devices. Especially, smart and flexible bioelectronics on graphene has emerged as a new frontier in this area.

Oct 31st, 2013

Catalysis is one of the most important routines for the production of nanomaterials. The catalysts that are used in these processes play a vital role for the controllable fabrication of nanomaterials with anticipated structures. However, carbon nanotubes grown through routine catalytic chemical vapor deposition have always shown non-carbon impurities. Effective purification of SWCNTs has therefore attracted significant attention from researchers around the world in order to improve the performance of carbon nanotubes, especially in energy storage systems.

Catalysis is one of the most important routines for the production of nanomaterials. The catalysts that are used in these processes play a vital role for the controllable fabrication of nanomaterials with anticipated structures. However, carbon nanotubes grown through routine catalytic chemical vapor deposition have always shown non-carbon impurities. Effective purification of SWCNTs has therefore attracted significant attention from researchers around the world in order to improve the performance of carbon nanotubes, especially in energy storage systems.

Oct 30th, 2013

The future of your clothes will be electronic. Not only will electronic devices be embedded on textile substrates, but an electronics device or system could become the fabric itself. These electronic textiles will have the revolutionary ability to sense, compute, store, emit, and move - think biomedical monitoring functions or new man-machine interfaces, not to mention game controllers - while leveraging an existing low-cost textile manufacturing infrastructure. In new work, a group of scientists from Korea have now reported novel method for the fabrication of conductive, flexible, and durable graphene textiles wrapped with reduced graphene oxide.

The future of your clothes will be electronic. Not only will electronic devices be embedded on textile substrates, but an electronics device or system could become the fabric itself. These electronic textiles will have the revolutionary ability to sense, compute, store, emit, and move - think biomedical monitoring functions or new man-machine interfaces, not to mention game controllers - while leveraging an existing low-cost textile manufacturing infrastructure. In new work, a group of scientists from Korea have now reported novel method for the fabrication of conductive, flexible, and durable graphene textiles wrapped with reduced graphene oxide.

Oct 29th, 2013

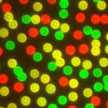

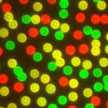

Colloidal quantum dot nanocrystals are attractive materials for optoelectronics, sensing devices and third generation photovoltaics. Researchers have now developed an automated, scalable, in-line synthesis methodology of high-quality colloidal quantum dots based on a flow-reactor with two temperature-stages of narrow channel coils. The flow-reactor methodology not only enables easy scalability and cheap production, but also affords rapid screening of parameters, automation, and low reagent consumption during optimization.

Colloidal quantum dot nanocrystals are attractive materials for optoelectronics, sensing devices and third generation photovoltaics. Researchers have now developed an automated, scalable, in-line synthesis methodology of high-quality colloidal quantum dots based on a flow-reactor with two temperature-stages of narrow channel coils. The flow-reactor methodology not only enables easy scalability and cheap production, but also affords rapid screening of parameters, automation, and low reagent consumption during optimization.

Oct 28th, 2013

Future electronics will look nothing like today's rigid boxes, be they the latest smartphones, tablets, or computers. Instead, they will be extremely light, soft, flexible, transparent, and integrated into everyday objects like paper or fabrics. These advanced electronic systems will be fabricated on soft substrates by integrating multiple crucial components such as logic and memory devices as well as their power supply. Researchers have now successfully demonstrated a rewritable, transferable, and flexible sticker-type organic memory on arbitrary nonconventional substrates through a simple, low-temperature and cost-effective one-step methodology.

Future electronics will look nothing like today's rigid boxes, be they the latest smartphones, tablets, or computers. Instead, they will be extremely light, soft, flexible, transparent, and integrated into everyday objects like paper or fabrics. These advanced electronic systems will be fabricated on soft substrates by integrating multiple crucial components such as logic and memory devices as well as their power supply. Researchers have now successfully demonstrated a rewritable, transferable, and flexible sticker-type organic memory on arbitrary nonconventional substrates through a simple, low-temperature and cost-effective one-step methodology.

Oct 25th, 2013

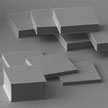

For microprobes, both the pick-up and placement are challenging due to the adherent forces. For microgrippers, the pick-up is easier and secure due to the gripping motion, but the placement is still difficult. When a microgripper opens its gripping fingers, the microobject still adheres to one of the fingers by strong adhesion forces. Owing to force scaling laws, the adhesion forces at the microscale - capillary forces, van der Waals forces, and electrostatic forces - dominate gravity. To overcome these challenges, researchers have developed a manufacturing route to three dimensional silicon microsystems, which they termed 'micro-masonry', based on individual manipulation.

For microprobes, both the pick-up and placement are challenging due to the adherent forces. For microgrippers, the pick-up is easier and secure due to the gripping motion, but the placement is still difficult. When a microgripper opens its gripping fingers, the microobject still adheres to one of the fingers by strong adhesion forces. Owing to force scaling laws, the adhesion forces at the microscale - capillary forces, van der Waals forces, and electrostatic forces - dominate gravity. To overcome these challenges, researchers have developed a manufacturing route to three dimensional silicon microsystems, which they termed 'micro-masonry', based on individual manipulation.

Oct 24th, 2013

One item that so far has been missing from graphene's impressive list of physical properties is magnetism. In its pristine state, graphene exhibits no signs of the conventional magnetism usually associated with such materials as iron or nickel. So far, no reports that provide comprehensive evidence for either macro- or nanoscale magnetic phenomena for the ferromagnetism of carbon nanostructures in chemically functionalized graphene structures have appeared in the literature. Researchers have now filled this gap.

One item that so far has been missing from graphene's impressive list of physical properties is magnetism. In its pristine state, graphene exhibits no signs of the conventional magnetism usually associated with such materials as iron or nickel. So far, no reports that provide comprehensive evidence for either macro- or nanoscale magnetic phenomena for the ferromagnetism of carbon nanostructures in chemically functionalized graphene structures have appeared in the literature. Researchers have now filled this gap.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed