Showing Spotlights 2033 - 2040 of 2783 in category All (newest first):

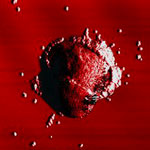

There is a slowly growing body of work that investigates the toxicity of synthesized nanoparticles to plants, aquatic invertebrates, algae, bacteria and different cell lines and we have been covering this topic in previous Spotlights as well as our nanoRISK newsletter. Although the potential negative effects of nanoparticles on organisms and the environment have raised concerns, limited studies so far have examined the difference between nanoparticles and bulk particles with the same chemical composition and mineral phase, or addressed the toxicity of dissolved metal ions from the nanoparticles. In new work by scientists at the University of Massachusetts, the toxicity of bulk oxide particles and the released ions were assessed along with four oxide nanoparticles, which clearly showed that size matters.

There is a slowly growing body of work that investigates the toxicity of synthesized nanoparticles to plants, aquatic invertebrates, algae, bacteria and different cell lines and we have been covering this topic in previous Spotlights as well as our nanoRISK newsletter. Although the potential negative effects of nanoparticles on organisms and the environment have raised concerns, limited studies so far have examined the difference between nanoparticles and bulk particles with the same chemical composition and mineral phase, or addressed the toxicity of dissolved metal ions from the nanoparticles. In new work by scientists at the University of Massachusetts, the toxicity of bulk oxide particles and the released ions were assessed along with four oxide nanoparticles, which clearly showed that size matters.

Apr 16th, 2009

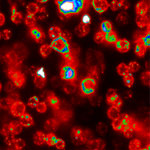

Cancer researchers are therefore experimenting with nanoparticles as both contrast agent and drug carrier capable of pinpointing and destroying individual cancer cells. Targeted nanoparticles consist of a metallic or organic core conjugated with a biomolecule of interest. To be able to navigate nanoparticles to a desired target (i.e. a specific cancer cell), they need the property of specific target recognition. Depending on the type of cancer that is to be targeted, researchers choose biomolecules that show high affinity toward these specific tumor cells. Think of these biomolecules as a navigation aid to transport nanoparticles to the cancerous site or organ of interest. As part of their overall goal of developing target-specific gold nanoparticles for treatment of cancers, scientists at the University of Missouri have carried out a systematic investigation on the design and development of targeted gold nanorods.

Cancer researchers are therefore experimenting with nanoparticles as both contrast agent and drug carrier capable of pinpointing and destroying individual cancer cells. Targeted nanoparticles consist of a metallic or organic core conjugated with a biomolecule of interest. To be able to navigate nanoparticles to a desired target (i.e. a specific cancer cell), they need the property of specific target recognition. Depending on the type of cancer that is to be targeted, researchers choose biomolecules that show high affinity toward these specific tumor cells. Think of these biomolecules as a navigation aid to transport nanoparticles to the cancerous site or organ of interest. As part of their overall goal of developing target-specific gold nanoparticles for treatment of cancers, scientists at the University of Missouri have carried out a systematic investigation on the design and development of targeted gold nanorods.

Apr 15th, 2009

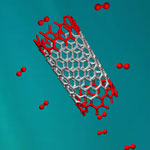

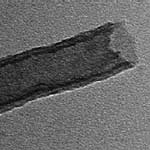

Researchers in Korea have developed a novel platform for intracellular delivery of genetic material and nanoparticles, based on vertically aligned carbon nanosyringe arrays of controllable height. Stem cell research is being pursued in laboratories all over the world in the hope of achieving major medical breakthroughs. Scientists are striving to create therapies that rebuild or replace damaged cells with tissues grown from stem cells and offer hope to people suffering from cancer, diabetes, cardiovascular disease, spinal-cord injuries, and many other disorders. Nanotechnology is increasingly playing a role in how researchers think about delivering stem cell therapies into cells. Cell plasma membranes are a formidable barrier to the delivery of exogenous macromolecules in cellular engineering and labeling and cell therapy. Attempts have been made to breach this barrier, particularly using mechanical means such as microinjectors that deliver genetic material into the cell. However, there is concern about damage to the cell membrane caused by intrinsic invasiveness of the micro- or submicrosized needle used in these procedures.

Researchers in Korea have developed a novel platform for intracellular delivery of genetic material and nanoparticles, based on vertically aligned carbon nanosyringe arrays of controllable height. Stem cell research is being pursued in laboratories all over the world in the hope of achieving major medical breakthroughs. Scientists are striving to create therapies that rebuild or replace damaged cells with tissues grown from stem cells and offer hope to people suffering from cancer, diabetes, cardiovascular disease, spinal-cord injuries, and many other disorders. Nanotechnology is increasingly playing a role in how researchers think about delivering stem cell therapies into cells. Cell plasma membranes are a formidable barrier to the delivery of exogenous macromolecules in cellular engineering and labeling and cell therapy. Attempts have been made to breach this barrier, particularly using mechanical means such as microinjectors that deliver genetic material into the cell. However, there is concern about damage to the cell membrane caused by intrinsic invasiveness of the micro- or submicrosized needle used in these procedures.

Apr 14th, 2009

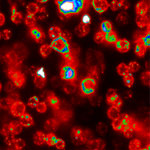

DNA nanomachines - synthetic DNA assemblies that switch between defined molecular shapes upon stimulation by external triggers - can be controlled by a variety of methods; these include pH changes and the addition of other molecular components, such as small molecule effectors, proteins and DNA strands. A team of Indian researchers has now taken structural DNA nanotechnology, where so far only in vitro applications have been demonstrated, across a new boundary and into living systems. They describe the successful operation of an artificially designed DNA nanomachine inside living cells, and show that these nanomachines work as efficiently inside cells as in vitro. The device is externally triggered by protons and functions as a pH sensor based on fluorescence resonance energy transfer (FRET) inside living cells.

DNA nanomachines - synthetic DNA assemblies that switch between defined molecular shapes upon stimulation by external triggers - can be controlled by a variety of methods; these include pH changes and the addition of other molecular components, such as small molecule effectors, proteins and DNA strands. A team of Indian researchers has now taken structural DNA nanotechnology, where so far only in vitro applications have been demonstrated, across a new boundary and into living systems. They describe the successful operation of an artificially designed DNA nanomachine inside living cells, and show that these nanomachines work as efficiently inside cells as in vitro. The device is externally triggered by protons and functions as a pH sensor based on fluorescence resonance energy transfer (FRET) inside living cells.

Apr 9th, 2009

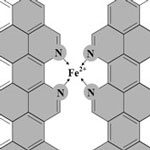

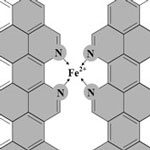

New work by this Canadian research team has now demonstrated that it is possible to significantly increase the catalytic site density of iron-based non-precious metal catalysts (NPMCs) to levels that were not thought possible before. The problem that this work resolves is that of the low activity of NPMCs compared to platinum-based catalysts. The best of these new NPMCs is more than 30 times more active compared to the previous best reported activity for NPMCs, and about 100 times more active than the majority of other NPMCs. Furthermore, their activity has reached about 1/10th the volumetric activity of state-of-the-art platinum-based catalysts (about 50 wt% platinum on carbon), which is the 2010 NPMC activity target set by the U.S. Department of Energy.

New work by this Canadian research team has now demonstrated that it is possible to significantly increase the catalytic site density of iron-based non-precious metal catalysts (NPMCs) to levels that were not thought possible before. The problem that this work resolves is that of the low activity of NPMCs compared to platinum-based catalysts. The best of these new NPMCs is more than 30 times more active compared to the previous best reported activity for NPMCs, and about 100 times more active than the majority of other NPMCs. Furthermore, their activity has reached about 1/10th the volumetric activity of state-of-the-art platinum-based catalysts (about 50 wt% platinum on carbon), which is the 2010 NPMC activity target set by the U.S. Department of Energy.

Apr 8th, 2009

NIOSH, the National Institute for Occupational Safety and Health in the United States, has published the final version of its report 'Approaches to Safe Nanotechnology'. This document reviews what is currently known about nanoparticle toxicity, process emissions and exposure assessment, engineering controls, and personal protective equipment. This updated version of the document incorporates some of the latest results of NIOSH research, but it is only a starting point. The document serves a dual purpose: it is a summary of NIOSH's current thinking and interim recommendations; and it is a request from NIOSH to occupational safety and health practitioners, researchers, product innovators and manufacturers, employers, workers, interest group members, and the general public to exchange information that will ensure that no worker suffers material impairment of safety or health as nanotechnology develops.

NIOSH, the National Institute for Occupational Safety and Health in the United States, has published the final version of its report 'Approaches to Safe Nanotechnology'. This document reviews what is currently known about nanoparticle toxicity, process emissions and exposure assessment, engineering controls, and personal protective equipment. This updated version of the document incorporates some of the latest results of NIOSH research, but it is only a starting point. The document serves a dual purpose: it is a summary of NIOSH's current thinking and interim recommendations; and it is a request from NIOSH to occupational safety and health practitioners, researchers, product innovators and manufacturers, employers, workers, interest group members, and the general public to exchange information that will ensure that no worker suffers material impairment of safety or health as nanotechnology develops.

Apr 7th, 2009

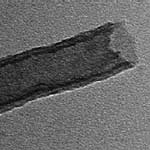

Notwithstanding the tremendous amount of research that has gone into the field of carbon nanotubes, the synthesis of single-walled carbon nanotubes (SWCNTs) with controlled chirality still has not been achieved. Current production methods for carbon nanotubes result in units with different diameter, length, chirality and electronic properties, all packed together in bundles, and often blended with some amount of amorphous carbon. The separation of nanotubes according to desired properties remains a technical challenge. Especially SWCNT sorting is a challenge because the composition and chemical properties of SWCNTs of different types are very similar, making conventional separation techniques inefficient. Using the concept of cloning, scientists in China have discovered an effective method to synthesize any special indices SWCNTs.

Notwithstanding the tremendous amount of research that has gone into the field of carbon nanotubes, the synthesis of single-walled carbon nanotubes (SWCNTs) with controlled chirality still has not been achieved. Current production methods for carbon nanotubes result in units with different diameter, length, chirality and electronic properties, all packed together in bundles, and often blended with some amount of amorphous carbon. The separation of nanotubes according to desired properties remains a technical challenge. Especially SWCNT sorting is a challenge because the composition and chemical properties of SWCNTs of different types are very similar, making conventional separation techniques inefficient. Using the concept of cloning, scientists in China have discovered an effective method to synthesize any special indices SWCNTs.

Apr 3rd, 2009

Not surprisingly, it has been scientists in The Netherlands - a country that has long been conducting large-scale and long-term field studies on the benefits of certain plants to mental and physical health (scientists refer to this effort as the 'great coffee house smoke screen studies') - that have come up with a nanotechnology discovery that could well revolutionize many consumer products from food to toys. In a report released today, April 1, the Dutch scientists report that a nanoparticulate substance found in Cannabis sativa, also know as marijuana, has an amazing ability to kill fat cells in the human body. Hoping to ride an early wave of commercialization, the Dutch research group has already filed for patent protection and registered the trademark 'Royal Spliffmeister Edition' for a range of planned products.

Not surprisingly, it has been scientists in The Netherlands - a country that has long been conducting large-scale and long-term field studies on the benefits of certain plants to mental and physical health (scientists refer to this effort as the 'great coffee house smoke screen studies') - that have come up with a nanotechnology discovery that could well revolutionize many consumer products from food to toys. In a report released today, April 1, the Dutch scientists report that a nanoparticulate substance found in Cannabis sativa, also know as marijuana, has an amazing ability to kill fat cells in the human body. Hoping to ride an early wave of commercialization, the Dutch research group has already filed for patent protection and registered the trademark 'Royal Spliffmeister Edition' for a range of planned products.

Apr 1st, 2009

There is a slowly growing body of work that investigates the toxicity of synthesized nanoparticles to plants, aquatic invertebrates, algae, bacteria and different cell lines and we have been covering this topic in previous Spotlights as well as our nanoRISK newsletter. Although the potential negative effects of nanoparticles on organisms and the environment have raised concerns, limited studies so far have examined the difference between nanoparticles and bulk particles with the same chemical composition and mineral phase, or addressed the toxicity of dissolved metal ions from the nanoparticles. In new work by scientists at the University of Massachusetts, the toxicity of bulk oxide particles and the released ions were assessed along with four oxide nanoparticles, which clearly showed that size matters.

There is a slowly growing body of work that investigates the toxicity of synthesized nanoparticles to plants, aquatic invertebrates, algae, bacteria and different cell lines and we have been covering this topic in previous Spotlights as well as our nanoRISK newsletter. Although the potential negative effects of nanoparticles on organisms and the environment have raised concerns, limited studies so far have examined the difference between nanoparticles and bulk particles with the same chemical composition and mineral phase, or addressed the toxicity of dissolved metal ions from the nanoparticles. In new work by scientists at the University of Massachusetts, the toxicity of bulk oxide particles and the released ions were assessed along with four oxide nanoparticles, which clearly showed that size matters.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed