Showing Spotlights 2433 - 2440 of 2779 in category All (newest first):

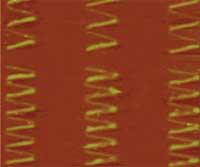

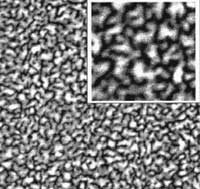

An incredible amount of research has gone, and still goes, into the understanding of the properties of nanoscale particles. In order to capitalize on that research, scientists and engineers have to take the next step, which is to turn nanoparticle laboratory results into usable materials and devices. One way to use engineered nanoparticles in the real world is in thin films. Nanoparticulate thin films are thin layers, sometimes only a few nanometers thick, of composite materials that contain nanoparticles. These new materials have a wide range of applications such as nanoelectronics, magnetic storage devices, or optical coating. However, most processes used to fabricate thin nanocomposite films with high nanoparticle fillings suffer from random nanoparticle agglomeration causing formation of irregularly shaped nanostructured features within the composite. Unfortunately, the improved mechanical, tribological and electrical properties of the nanocomposites over the host matrix materials (mostly polymers) are only attainable if the nanoparticle inclusions are of uniform size and shape with very good degree of dispersion. A newly developed technique now allows a wide range of control of including metal nanoparticle into polymer matrices in a single step process.

An incredible amount of research has gone, and still goes, into the understanding of the properties of nanoscale particles. In order to capitalize on that research, scientists and engineers have to take the next step, which is to turn nanoparticle laboratory results into usable materials and devices. One way to use engineered nanoparticles in the real world is in thin films. Nanoparticulate thin films are thin layers, sometimes only a few nanometers thick, of composite materials that contain nanoparticles. These new materials have a wide range of applications such as nanoelectronics, magnetic storage devices, or optical coating. However, most processes used to fabricate thin nanocomposite films with high nanoparticle fillings suffer from random nanoparticle agglomeration causing formation of irregularly shaped nanostructured features within the composite. Unfortunately, the improved mechanical, tribological and electrical properties of the nanocomposites over the host matrix materials (mostly polymers) are only attainable if the nanoparticle inclusions are of uniform size and shape with very good degree of dispersion. A newly developed technique now allows a wide range of control of including metal nanoparticle into polymer matrices in a single step process.

Jul 10th, 2007

New technology, whether it is a novel cancer treatment or an innovative approach to farming, almost always comes with risk. Those risks are often first - and most severely - felt by industry workers, and nanotechnology is no different. Today, workers around the world are exposed to nanoparticles on a daily basis. There is much speculation, yet so far, little definitive information about how exposure affects workers. A report released by the International Council on Nanotechnology in November 2006, offers a clear picture of the situation. "The properties for which novel nanoscale materials are designed may generate new risks to workers, consumers, the public, and the environment. While some of these risks can be anticipated from experiences with other synthetic chemicals and with existing knowledge of ambient and manufactured fine particles, novel risks associated with new properties cannot easily be anticipated based on existing data." Questions, such as how to measure toxicity and how to monitor and control exposure, remain unanswered.

New technology, whether it is a novel cancer treatment or an innovative approach to farming, almost always comes with risk. Those risks are often first - and most severely - felt by industry workers, and nanotechnology is no different. Today, workers around the world are exposed to nanoparticles on a daily basis. There is much speculation, yet so far, little definitive information about how exposure affects workers. A report released by the International Council on Nanotechnology in November 2006, offers a clear picture of the situation. "The properties for which novel nanoscale materials are designed may generate new risks to workers, consumers, the public, and the environment. While some of these risks can be anticipated from experiences with other synthetic chemicals and with existing knowledge of ambient and manufactured fine particles, novel risks associated with new properties cannot easily be anticipated based on existing data." Questions, such as how to measure toxicity and how to monitor and control exposure, remain unanswered.

Jul 9th, 2007

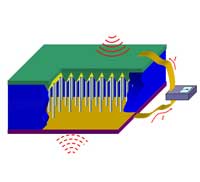

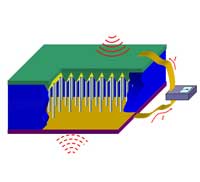

For the over 100 million people worldwide who suffer from diabetes, testing blood glucose is the only way to be sure that it is within normal range and allows them to adjust the insulin dose if it is not. The current method for monitoring blood glucose requires poking your finger to obtain a blood sample. The equipment needed to perform the blood test includes a needle device for drawing blood, a blood glucose meter, single-use test strips, and a log book. Now imagine this scenario: your doctor implants a tiny device the size of a rice grain under your skin. This device automatically and accurately measures your blood glucose levels at whatever intervals, even constantly if required. It transmits the data to an external transceiver. If any abnormality is detected, the device warns you and automatically transmits the data to your doctor's computer. This scenario is one of the many promises of nanomedicine where in-situ, real-time and implantable biosensing, biomedical monitoring and biodetection will become an everyday fact of normal healthcare. Nanosensors are already under intense development in laboratories around the world. One of the important components for implantable nanosensors is an independent power source, either a nanobattery or a nanogenerator that harvests energy from its environment, so that the sensor can operate autonomously. Not only has such a nanogenerator now been developed, but a new prototype has been demonstrated to effectively generate electricity inside biofluid, e.g. blood. This is an important step towards self-powered nanosystems.

For the over 100 million people worldwide who suffer from diabetes, testing blood glucose is the only way to be sure that it is within normal range and allows them to adjust the insulin dose if it is not. The current method for monitoring blood glucose requires poking your finger to obtain a blood sample. The equipment needed to perform the blood test includes a needle device for drawing blood, a blood glucose meter, single-use test strips, and a log book. Now imagine this scenario: your doctor implants a tiny device the size of a rice grain under your skin. This device automatically and accurately measures your blood glucose levels at whatever intervals, even constantly if required. It transmits the data to an external transceiver. If any abnormality is detected, the device warns you and automatically transmits the data to your doctor's computer. This scenario is one of the many promises of nanomedicine where in-situ, real-time and implantable biosensing, biomedical monitoring and biodetection will become an everyday fact of normal healthcare. Nanosensors are already under intense development in laboratories around the world. One of the important components for implantable nanosensors is an independent power source, either a nanobattery or a nanogenerator that harvests energy from its environment, so that the sensor can operate autonomously. Not only has such a nanogenerator now been developed, but a new prototype has been demonstrated to effectively generate electricity inside biofluid, e.g. blood. This is an important step towards self-powered nanosystems.

Jul 6th, 2007

If you have seen the movie The Matrix then you are familiar with 'jacking in' - a brain-machine neural interface that connects a human brain to a computer network. For the time being, this is still a sci-fi scenario, but don't think that researchers are not heavily working on it. What is already reality today is something called neuroprosthetics, an area of neuroscience that uses artificial microdevices to replace the function of impaired nervous systems or sensory organs. Different biomedical devices implanted in the central nervous system, so-called neural interfaces, already have been developed to control motor disorders or to translate willful brain processes into specific actions by the control of external devices. These implants could help increase the independence of people with disabilities by allowing them to control various devices with their thoughts (not surprisingly, the other candidate for early adoption of this technology is the military). The potential of nanotechnology application in neuroscience is widely accepted. Especially single-walled carbon nanotubes (SWCNT) have received great attention because of their unique physical and chemical features, which allow the development of devices with outstanding electrical properties. In a crucial step towards a new generation of future neuroprosthetic devices, a group of European scientists developed a SWCNT/neuron hybrid system and demonstrated that carbon nanotubes can directly stimulate brain circuit activity.

If you have seen the movie The Matrix then you are familiar with 'jacking in' - a brain-machine neural interface that connects a human brain to a computer network. For the time being, this is still a sci-fi scenario, but don't think that researchers are not heavily working on it. What is already reality today is something called neuroprosthetics, an area of neuroscience that uses artificial microdevices to replace the function of impaired nervous systems or sensory organs. Different biomedical devices implanted in the central nervous system, so-called neural interfaces, already have been developed to control motor disorders or to translate willful brain processes into specific actions by the control of external devices. These implants could help increase the independence of people with disabilities by allowing them to control various devices with their thoughts (not surprisingly, the other candidate for early adoption of this technology is the military). The potential of nanotechnology application in neuroscience is widely accepted. Especially single-walled carbon nanotubes (SWCNT) have received great attention because of their unique physical and chemical features, which allow the development of devices with outstanding electrical properties. In a crucial step towards a new generation of future neuroprosthetic devices, a group of European scientists developed a SWCNT/neuron hybrid system and demonstrated that carbon nanotubes can directly stimulate brain circuit activity.

Jul 5th, 2007

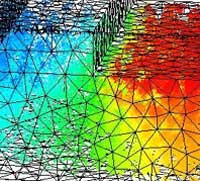

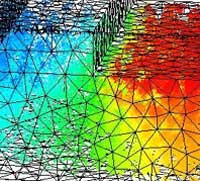

Continuing miniaturization has moved the semiconductor industry into the nano realm with leading chip manufacturers well on their way to CPUs using 32nm process technology (expected by 2009). There are some real challenges ahead for chip designers, particularly in moving deeper and deeper into the nanoscale, where at some point in the near future they will reach physical limits of the traditional logic MOSFET (metal-oxide-semiconductor field-effect transistor) structure. In addition to physical barriers, semiconductor companies will also reach economic barriers where profitability will be squeezed hard in view of the exorbitant costs of building the necessary manufacturing capabilities if present day technologies are extrapolated. Quantum and coherence effects, high electric fields creating avalanche dielectric breakdowns, heat dissipation problems in closely packed structures and the relevance of single atom defects are all roadblocks along the current road of miniaturization. Enter nanoelectronics (note that microelectronics, even if the gate size of the transistor is below 100 nm, is not an implementation of nanoelectronics, as no new qualitative physical property related to reduction in size are being exploited). Its goal is to process, transmit and store information by taking advantage of properties of matter that are distinctly different from macroscopic properties. Understanding nanoscale transport and being able to model and simulate nanodevices requires an entirely new generation of simulation tools and techniques.

Continuing miniaturization has moved the semiconductor industry into the nano realm with leading chip manufacturers well on their way to CPUs using 32nm process technology (expected by 2009). There are some real challenges ahead for chip designers, particularly in moving deeper and deeper into the nanoscale, where at some point in the near future they will reach physical limits of the traditional logic MOSFET (metal-oxide-semiconductor field-effect transistor) structure. In addition to physical barriers, semiconductor companies will also reach economic barriers where profitability will be squeezed hard in view of the exorbitant costs of building the necessary manufacturing capabilities if present day technologies are extrapolated. Quantum and coherence effects, high electric fields creating avalanche dielectric breakdowns, heat dissipation problems in closely packed structures and the relevance of single atom defects are all roadblocks along the current road of miniaturization. Enter nanoelectronics (note that microelectronics, even if the gate size of the transistor is below 100 nm, is not an implementation of nanoelectronics, as no new qualitative physical property related to reduction in size are being exploited). Its goal is to process, transmit and store information by taking advantage of properties of matter that are distinctly different from macroscopic properties. Understanding nanoscale transport and being able to model and simulate nanodevices requires an entirely new generation of simulation tools and techniques.

Jul 3rd, 2007

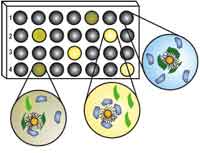

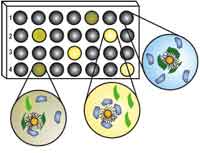

Biomarkers are of increasing importance in modern medicine for the purpose of early detection and diagnosis of a disease, for instance cancer. Biomarkers are mostly protein molecules that can be measured in blood, other body fluids, and tissues to assess the presence or state of a disease. For example, the presence of an antibody may indicate an infection or an antigen, such as PSA, might indicate the presence of prostate-specific cancer cells. Although protein-based approaches to early detection and diagnosis of cancer have a clear advantage over other, more invasive, methods, protein detection is a challenging problem owing to the structural diversity and complexity of the target analytes. State-of-the-art detection methods have limited application due to their high production cost and instability. Another limitation of current proteomic diagnostics is the limitation of arrays to one or a few markers only; in other words, you can only test for the specific markers that you are looking for and not generally measure levels of proteins in your blood in order to detect anomalies. A novel nanotechnology based protein detector array could change that.

Biomarkers are of increasing importance in modern medicine for the purpose of early detection and diagnosis of a disease, for instance cancer. Biomarkers are mostly protein molecules that can be measured in blood, other body fluids, and tissues to assess the presence or state of a disease. For example, the presence of an antibody may indicate an infection or an antigen, such as PSA, might indicate the presence of prostate-specific cancer cells. Although protein-based approaches to early detection and diagnosis of cancer have a clear advantage over other, more invasive, methods, protein detection is a challenging problem owing to the structural diversity and complexity of the target analytes. State-of-the-art detection methods have limited application due to their high production cost and instability. Another limitation of current proteomic diagnostics is the limitation of arrays to one or a few markers only; in other words, you can only test for the specific markers that you are looking for and not generally measure levels of proteins in your blood in order to detect anomalies. A novel nanotechnology based protein detector array could change that.

Jul 2nd, 2007

Nanotechnology will play an important role in future space missions. Nanosensors, dramatically improved high-performance materials, or highly efficient propulsion systems are but a few examples. In previous Nanowerk Spotlights we reported about nanotechnology propulsion technology, such as nano field emission thrusters, and the use of carbon nanotubes to harden electronic components in space. This last aspect, radiation shielding, is also where nanotechnology could make a major contribution to human space flight. NASA says that the risks of exposure to space radiation are the most significant factor limiting humans�?? ability to participate in long-duration space missions. A lot of research therefore focuses on developing countermeasures to protect astronauts from those risks. To meet the needs for radiation protection as well as other requirements such as low weight and structural stability, spacecraft designers are looking for materials that help them develop multifunctional spacecraft hulls. Advanced nanomaterials such as the newly developed, isotopically enriched boron nanotubes could pave the path to future spacecraft with nanosensor-integrated hulls that provide effective radiation shielding as well as energy storage.

Nanotechnology will play an important role in future space missions. Nanosensors, dramatically improved high-performance materials, or highly efficient propulsion systems are but a few examples. In previous Nanowerk Spotlights we reported about nanotechnology propulsion technology, such as nano field emission thrusters, and the use of carbon nanotubes to harden electronic components in space. This last aspect, radiation shielding, is also where nanotechnology could make a major contribution to human space flight. NASA says that the risks of exposure to space radiation are the most significant factor limiting humans�?? ability to participate in long-duration space missions. A lot of research therefore focuses on developing countermeasures to protect astronauts from those risks. To meet the needs for radiation protection as well as other requirements such as low weight and structural stability, spacecraft designers are looking for materials that help them develop multifunctional spacecraft hulls. Advanced nanomaterials such as the newly developed, isotopically enriched boron nanotubes could pave the path to future spacecraft with nanosensor-integrated hulls that provide effective radiation shielding as well as energy storage.

Jun 29th, 2007

Nanoimprinting lithography (NIL) is a simple pattern transfer process that is emerging as an alternative nanopatterning technology to traditional photolithography. NIL allows the fabrication of two-dimensional or three-dimensional structures with submicrometer resolution and the patterning and modification of functional materials. A key benefit of nanoimprint lithography is its sheer simplicity. There is no need for complex optics or high-energy radiation sources with a nanoimprint tool. There is no need for finely tailored photoresists designed for both resolution and sensitivity at a given wavelength. The simplified requirements of the technology allow low-cost, high-throughput production processes of various nanostructures with operational ease. NIL already has been applied in various fields such as biological nanodevices, nanophotonic devices, organic electronics, and the patterning of magnetic materials. Researchers at Berkeley have taken this process one step further by demonstrating that direct nanoimprinting of metal nanoparticles enables low temperature metal deposition as well as high-resolution patterning. This approach has substantial potential to take advantage of nanoimprinting for the application in ultralow cost, large area printed electronics.

Nanoimprinting lithography (NIL) is a simple pattern transfer process that is emerging as an alternative nanopatterning technology to traditional photolithography. NIL allows the fabrication of two-dimensional or three-dimensional structures with submicrometer resolution and the patterning and modification of functional materials. A key benefit of nanoimprint lithography is its sheer simplicity. There is no need for complex optics or high-energy radiation sources with a nanoimprint tool. There is no need for finely tailored photoresists designed for both resolution and sensitivity at a given wavelength. The simplified requirements of the technology allow low-cost, high-throughput production processes of various nanostructures with operational ease. NIL already has been applied in various fields such as biological nanodevices, nanophotonic devices, organic electronics, and the patterning of magnetic materials. Researchers at Berkeley have taken this process one step further by demonstrating that direct nanoimprinting of metal nanoparticles enables low temperature metal deposition as well as high-resolution patterning. This approach has substantial potential to take advantage of nanoimprinting for the application in ultralow cost, large area printed electronics.

Jun 27th, 2007

An incredible amount of research has gone, and still goes, into the understanding of the properties of nanoscale particles. In order to capitalize on that research, scientists and engineers have to take the next step, which is to turn nanoparticle laboratory results into usable materials and devices. One way to use engineered nanoparticles in the real world is in thin films. Nanoparticulate thin films are thin layers, sometimes only a few nanometers thick, of composite materials that contain nanoparticles. These new materials have a wide range of applications such as nanoelectronics, magnetic storage devices, or optical coating. However, most processes used to fabricate thin nanocomposite films with high nanoparticle fillings suffer from random nanoparticle agglomeration causing formation of irregularly shaped nanostructured features within the composite. Unfortunately, the improved mechanical, tribological and electrical properties of the nanocomposites over the host matrix materials (mostly polymers) are only attainable if the nanoparticle inclusions are of uniform size and shape with very good degree of dispersion. A newly developed technique now allows a wide range of control of including metal nanoparticle into polymer matrices in a single step process.

An incredible amount of research has gone, and still goes, into the understanding of the properties of nanoscale particles. In order to capitalize on that research, scientists and engineers have to take the next step, which is to turn nanoparticle laboratory results into usable materials and devices. One way to use engineered nanoparticles in the real world is in thin films. Nanoparticulate thin films are thin layers, sometimes only a few nanometers thick, of composite materials that contain nanoparticles. These new materials have a wide range of applications such as nanoelectronics, magnetic storage devices, or optical coating. However, most processes used to fabricate thin nanocomposite films with high nanoparticle fillings suffer from random nanoparticle agglomeration causing formation of irregularly shaped nanostructured features within the composite. Unfortunately, the improved mechanical, tribological and electrical properties of the nanocomposites over the host matrix materials (mostly polymers) are only attainable if the nanoparticle inclusions are of uniform size and shape with very good degree of dispersion. A newly developed technique now allows a wide range of control of including metal nanoparticle into polymer matrices in a single step process.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed