| Posted: Oct 06, 2017 |

Segregation-induced ordered superstructures at general grain boundaries in a Ni-Bi alloy

(Nanowerk News) A team of researchers found that randomly selected, high-angle, general grain boundaries in a nickel-bismuth (Ni-Bi) polycrystalline alloy can undergo interfacial reconstruction to form ordered superstructures, a discovery that enriches the theories and fundamental understandings of both grain boundary segregation and liquid metal embrittlement in physical metallurgy.

|

|

This discovery shows that segregation-induced ordered superstructures are not limited to special grain boundaries that are inherently periodic, but may exist at a variety of general grain boundaries that were thought to be lacking any long-range order; hence, they can affect the performance of polycrystalline engineering alloys.

|

|

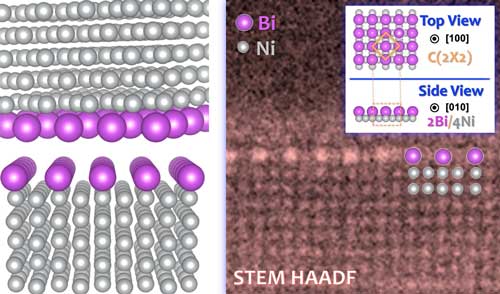

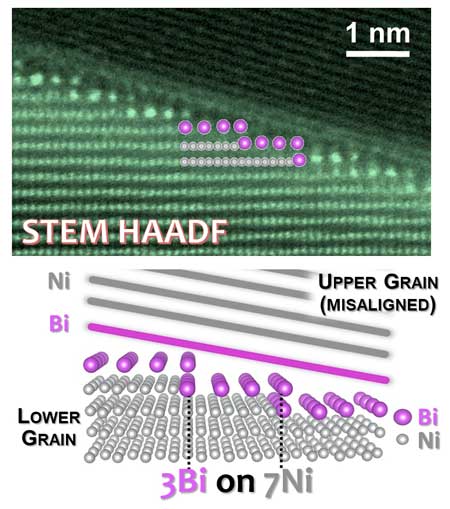

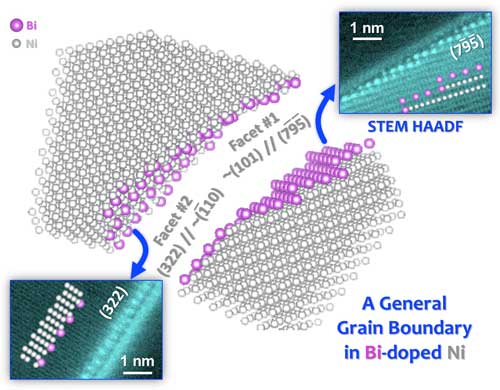

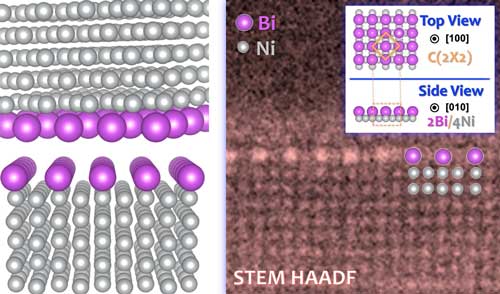

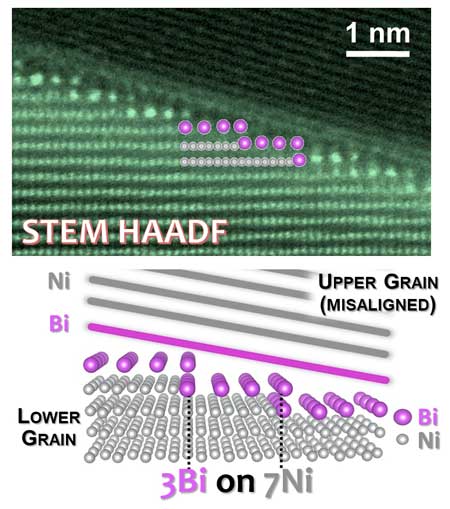

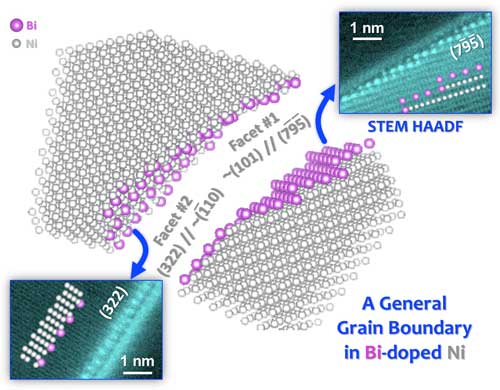

| Atomistic models and atomic-resolution STEM HAADF (scanning transmission electron microscopic high-angle annular dark-field) images showing three examples of segregation-induced superstructures observed at randomly-selected general grain boundaries of a nickel-bismuth (Ni-Bi) polycrystalline alloy. The formation of such ordered superstructures and the associated interfacial reconstructions that change the 2-D translational symmetries at both terminating grain planes, which had been thought impossible to be realized at general grain boundaries that should be lacking a long-range translational symmetry according to the classical theories in physical metallurgy, are enabled by faceting, as well as the formation of atomic-level steps at the grain boundaries. This somewhat surprising discovery enriches our fundamental knowledge of the atomic-level segregation structures at general grain boundaries, which are important in controlling a broad range of mechanical and physical properties of polycrystalline alloys. Specific to this nickel-bismuth system, such interfacial superstructures are the root cause of a mysterious phenomenon called “liquid metal embrittlement,” wherein a normally ductile nickel metal or nickel-based alloy can fail catastrophically in an extremely brittle manner in contact with a bismuth-based liquid metal. (Image: University of California San Diego)

|

|

The team, including nanoengineering professor Jian Luo here at the University of California San Diego as a co-corresponding author together with Professor Martin Harmer at Lehigh University, lays out their findings in Science ("Segregation-induced ordered superstructures at general grain boundaries in a nickel-bismuth alloy").

|

|

Researchers observed and investigated segregation-induced superstructures at randomly-selected general grain boundaries of a Ni-Bi polycrystalline alloy via aberration-corrected scanning transmission electron microscopy (AC STEM), in conjunction with first-principles density functional theory calculations.

|

|

Grain boundaries are internal interfaces in polycrystalline materials that often control the materials’ properties. The segregation of alloying elements or impurities at grain boundaries can significantly alter, often severely degrade, the mechanical and physical properties of engineered alloys.

|

|

Prior studies of atomic-level grain boundary and segregation structures have been mostly focused on small-angle or special symmetrical tilt and twist boundaries with high symmetries and well-defined periodicities in artificial bicrystals. However, most grain boundaries in polycrystalline materials are so-called “general” grain boundaries of mixed tilt and twist character, which are not well understood due to the difficulties in characterizing and modeling them. Yet, such general grain boundaries are often significantly weaker mechanically and chemically than the well-studied special grain boundaries, thereby limiting properties and performance of engineered materials. Here, a traditional view is that these high-angle general grain boundaries may not undergo interfacial reconstructions to form ordered superstructures because a lattice match between the two abutting grains is lacking. This traditional belief is challenged by this new report in Science.

|

|

| Atomistic models and atomic-resolution STEM HAADF (scanning transmission electron microscopic high-angle annular dark-field) images showing three examples of segregation-induced superstructures observed at randomly-selected general grain boundaries of a nickel-bismuth (Ni-Bi) polycrystalline alloy. The formation of such ordered superstructures and the associated interfacial reconstructions that change the 2-D translational symmetries at both terminating grain planes, which had been thought impossible to be realized at general grain boundaries that should be lacking a long-range translational symmetry according to the classical theories in physical metallurgy, are enabled by faceting, as well as the formation of atomic-level steps at the grain boundaries. This somewhat surprising discovery enriches our fundamental knowledge of the atomic-level segregation structures at general grain boundaries, which are important in controlling a broad range of mechanical and physical properties of polycrystalline alloys. Specific to this nickel-bismuth system, such interfacial superstructures are the root cause of a mysterious phenomenon called “liquid metal embrittlement,” wherein a normally ductile nickel metal or nickel-based alloy can fail catastrophically in an extremely brittle manner in contact with a bismuth-based liquid metal. (Image: University of California San Diego)

|

|

More specifically, interfacial reconstructions that change the 2-D translational symmetries, which are known to occur frequently at crystalline surfaces, were thought impossible to be realized at general grain boundaries that should be lacking long-range translational symmetries. But researchers showed that it is enabled by faceting, as well as the formation of atomic-level steps at the grain boundaries, which allows separate interfacial reconstructions to occur at both terminating grain surface planes in a unique “bilayer” interfacial phase (wherein an “interfacial phase” refers to a thermodynamically 2-D phase spontaneously-formed at an interface, which is also called a “complexion”).

|

|

Specific to this nickel-bismuth system, such interfacial superstructures are the root cause of a mysterious phenomenon called “liquid metal embrittlement,” wherein a normally ductile nickel metal or nickel-based alloy can fail catastrophically in an extremely brittle manner in contact with a bismuth-based liquid metal.

|

|

This work is a further, significant advancement of Luo’s earlier collaborative research with Lehigh University published six years ago (Science, "The Role of a Bilayer Interfacial Phase on Liquid Metal Embrittlement").

|

|

| Atomistic models and atomic-resolution STEM HAADF (scanning transmission electron microscopic high-angle annular dark-field) images showing three examples of segregation-induced superstructures observed at randomly-selected general grain boundaries of a nickel-bismuth (Ni-Bi) polycrystalline alloy. The formation of such ordered superstructures and the associated interfacial reconstructions that change the 2-D translational symmetries at both terminating grain planes, which had been thought impossible to be realized at general grain boundaries that should be lacking a long-range translational symmetry according to the classical theories in physical metallurgy, are enabled by faceting, as well as the formation of atomic-level steps at the grain boundaries. This somewhat surprising discovery enriches our fundamental knowledge of the atomic-level segregation structures at general grain boundaries, which are important in controlling a broad range of mechanical and physical properties of polycrystalline alloys. Specific to this nickel-bismuth system, such interfacial superstructures are the root cause of a mysterious phenomenon called “liquid metal embrittlement,” wherein a normally ductile nickel metal or nickel-based alloy can fail catastrophically in an extremely brittle manner in contact with a bismuth-based liquid metal. (Image: University of California San Diego)

|

|

In that earlier work, researchers discovered this bilayer interfacial phase that is responsible for the mysterious liquid metal embrittlement in nickel-bismuth, but the exact atomic structures of the bilayers had not been determined at that time. Specifically, it was unclear whether the segregated bismuth atoms can form reconstructed superstructures, the existence of which was not expected at the general grain boundaries, but have been revealed in this new study. Another scientifically interesting observation of the current study is that the interfacial reconstruction is driven and dictated by the orientation of the terminating grain surface, rather than by lattice mis-orientation between the two abutting grains as commonly believed in classical physical metallurgy.

|

|

Researchers believe that these new and somewhat surprising discoveries are scientifically important and enrich our fundamental understanding of the general grain boundaries that often control the performance properties of various polycrystalline engineered materials.

|