| Jun 11, 2014 |

Lighter cars with new robotic welding method

|

|

(Nanowerk News) A vehicle typically consists of several thousands of spot joints such as rivets, clinch joints or spot welds. They are used to bond together different parts of the vehicle, for example the car bonnet. But the rivets are costly and do not have great strength. Moreover, spot joints require a certain sheet thickness to provide sufficient strength. At the same time, however, the automotive industry is keen to use thinner sheets, in order to build lighter vehicles and reduce production costs. More and more car manufacturers choose a hybrid design, where a combination of different materials such as steel and aluminium are joined.

|

|

With classic welding methods, joining of dissimilar materials has not been possible. With friction stir welding, on the other hand, high quality dissimilar joints can be obtained. The welding temperature is kept below the melting point, which means that the alloy properties are not destroyed and strong joints are achieved.

|

|

|

In FSW, a rotating non-consumable cylinder is pressed into the material. The combination of frictional heat and the mechanical “stirring” creates a high-quality welding joint, without melting the material.

|

|

One of the problems with this method has been that the temperature becomes excessively high, with the result that the metals reach the melting point and the welding tool sinks through the sheets. In order to achieve good welds with a FSW robot, both the process forces and the temperature must be properly controlled.

|

|

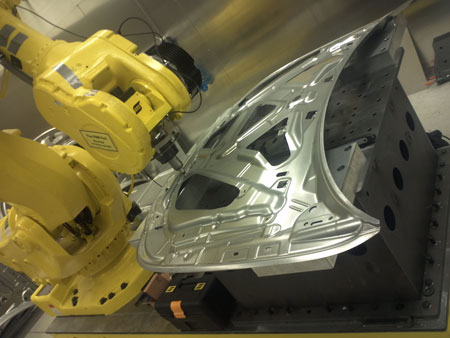

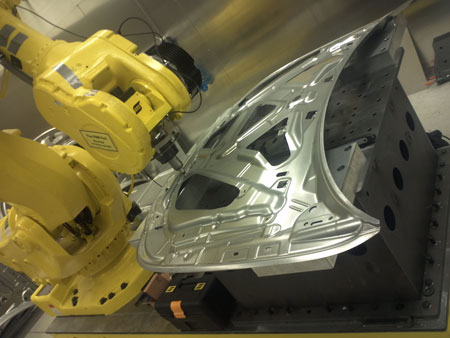

Researchers at University West in Trollhättan have now invented a welding tool that also functions as a temperature sensor. The temperature is measured continuously and, if it becomes too hot, the heat is regulated by controlling the force and tool rotation. The researchers have also made use of an industrial robot to perform the welds and achieve a constant welding quality. Jeroen De Backer has written his thesis on this new method:

|

|

“It’s thanks to this temperature controller that we’ve managed to raise both the quality and the productivity of the robot system. The robot welds with higher precision and with the temperature controller it only takes a few hours to programme 3D joints. Manual programming of a similar component took up to a week.”

|

|

With the aid of the robot, and the temperature measurement, the researchers have also been able to weld advanced three-dimensional joints. This enables the welding of small and more complex components with curved surfaces. Furthermore, the energy consumption of FSW is lower than when using conventional welding methods.

|

|

The research project at University West was initiated through a collaboration between Volvo Aero, SAAB Automobile and the welding equipment company ESAB. Jeroen De Backer explains that a possible application can be hybrid and electric vehicles: “Car manufacturers aim to reduce the weight of the electric vehicle and positioning of the heavy batteries is a key factor in this. The battery consists of different metals such as aluminium and copper. Friction stir welding provides the possibility to join those materials and allows thereby integration of the battery in the vehicle chassis so that the battery becomes a part of the bearing structure.

|