MEMS Explained – A Comprehensive Guide to Microelectromechanical Systems

Content

MEMS is an acronym that stands for microelectromechanical systems – exceptionally small devices that incorporate mechanical, electrical, and frequently optical components on a single microchip. These devices, despite their micro scale, perform a wide array of functions, from sensing and actuating to data processing and communication. MEMS technology has redefined modern technology, leading to improved performance and innovative applications across diverse industries. Take for example an airbag, where the (microscale) accelerometer in the airbag’s control unit can trigger the rapid inflation of the (macroscale) airbag when it senses a sudden change in velocity.

What is MEMS technology?

MEMS are mechanical sensors and actuators that are fabricated using micromachining batch technologies similar to those used for integrated circuits. This translates into highly scalable production processes and low per-device production costs.

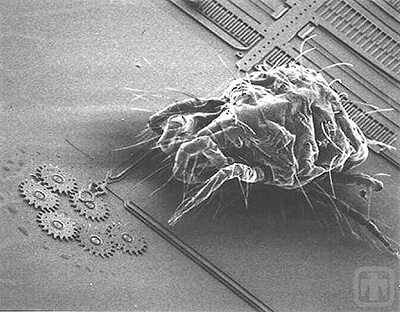

MEMS have feature sizes ranging from micrometers to millimeters. To see how small that is, consider that a regular sheet of paper is between 70 and 180 micrometers thick.

The one main criterion of MEMS is that there are at least some elements having some sort of mechanical functionality whether or not these elements can move. MEMS devices can vary from simple structures with no moving elements, to extremely complex electromechanical microsystems with several moving elements under the control of integrated microelectronics.

The evolution of MEMS technology

Starting in the 1960s, MEMS began to make their way out of research laboratories and into everyday products. In 1964, Harvey Nathanson from Westinghouse developed the first batch fabricated surface micromachined MEMS device, called the resonant gate transistor

In the mid-1990's, MEMS emerged in industrial manufacturing in a major way and MEMS components began appearing in numerous commercial products and applications including force sensors used to control brake deployment in vehicles, blood pressure sensors, inkjet printer heads, miniature analytical instruments, fiber-optic network components, air- and spacecraft control and of course military applications like surveillance and munitions guidance.

Nowadays, every modern automobile and smartphone is equipped with dozens of MEMS sensors and actuators – accelerometers, gyroscopes, compass, motion sensor, pressure sensors, proximity sensor, image sensors, micro-mirrors...

Key components of MEMS devices

MEMS consist of any combination of mechanical (levers, springs, membranes, combs, channels) and electrical (resistors, capacitors, inductors, etc.) components to work as sensors or actuators.

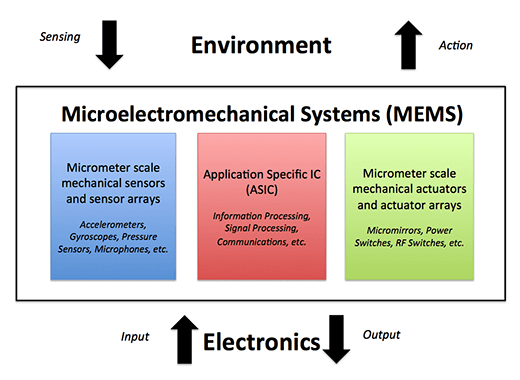

In their most general form, MEMS consist of four elements: mechanical microstructures, microsensors, micro-actuators and micro-electronics, all integrated onto the same chip.

MEMS can act as sensors, receiving information from their environment and providing an electrical output signal, or as actuators, devices that convert an electrical signal into an action as required by a decision from the control system. Both sensors and actuators are transducers, devices that transforms one form of signal or energy into another form.

A MEMS device typically contains a microelectromechanical sensor or actuator element packaged together with an integrated circuit (IC). The IC provides an electrical interface to the sensor or actuator, signal processing / compensation, and an analog or digital output.

Whereas the IC exploits the electrical properties of silicon, MEMS takes advantage of other material properties like optical, mechanical, thermal, magnetic, chemical, etc.

For example, MEMS are used as accelerometers in modern automobile airbags where they sense rapid deceleration and, if the force is beyond a programmed threshold, initiate the inflation of the airbag.

The size of today's smartphones would be impossible without the use of numerous MEMS devices. A simple function like rotating the screen of your phone or tablet requires a MEMS. Apart from accelerometers and gyroscopes, smartphones contain micro-mirrors, image sensors, auto-focus actuators, pressure sensors, magnetometers, microphones, proximity sensors and many more.

MEMS Fabrication

The fabrication of microelectromechanical systems uses some of the same processes and tools used to fabricate integrated circuits (e.g., deposition, photolithography, etch). However, MEMS technology has altered or enhanced some of these techniques, as well as added new processes, in order to build mechanical devices such as microfluidic channels, gears, cantilevers, micro motors, comb drives and gyroscopes.

These adopted techniques for MEMS fabrication are also called micromachining:

Bulk micromachining etches into a substrate to form 3D mechanical elements such as channels, chambers and valves.

Surface micromachining constructs microscale mechanical components and systems on the surface of a substrate by alternately depositing, patterning and etching thin films.

High-aspect-ratio micromachining (HARM), which includes technology such as LIGA (a German acronym from Lithographie, Galvanoformung, Abformung translated as lithography, electroforming and molding), combines collimated x-ray lithography with electroplating and molding techniques to create high aspect ratio (tall and thin) structures or deep cavities needed for certain types of MEMS devices.

Most laser micromachining processes are not parallel and hence not fast enough for effective MEMS fabrication. Nonetheless, they have utility in specialty micromachining or making molds.

Unlike the batch manufacturing technologies used for integrated circuits, the MEMS industry does not share a generic technology platform like the semiconductor industry.

On the contrary. There are dozens of MEMS product groups, each containing several different products for specific applications and markets, and each of these product groups relies on its own, often unique, technology.

If you want to delve deeper into MEMS fabrication, the Support Center for Microsystems Education has some excellent and comprehensive educational materials here on their website.

MEMS Applications

Applications of MEMS MEMS technology has been instrumental in shaping numerous industries:

Automotive: MEMS devices are used in applications such as airbag deployment systems, tire pressure monitoring, electronic stability control, and inertial navigation systems, enhancing vehicle safety, efficiency, and performance.

Biomedical: In healthcare, MEMS enables advancements in drug delivery systems, lab-on-a-chip devices, implantable sensors, and microfluidic devices. Other applications include pressure sensors used for instance to monitor blood pressure in IV lines of patients in intensive care; respiratory monitoring in ventilators; inhalers; kidney dialysis; drug infusion pumps; MEMS electrodes used in neuro-signal detection and neuro-stimulation applications. These innovations have the potential to enhance patient care and improve diagnostics and treatment outcomes.

MEMS tweezers or miniature robot arms that move, rotate, cut and place cells.

Consumer Electronics: MEMS devices are ubiquitous in consumer electronics. Accelerometers and gyroscopes in smartphones, MEMS microphones, and MEMS-based pico-projectors enhance user experience and functionality.

Aerospace and Defense: MEMS devices contribute to applications like navigation systems, unmanned aerial vehicles (UAVs), satellite systems, and pressure sensors. They provide lightweight, reliable, and cost-effective solutions for mission-critical applications.

Optical applications of MEMS: Micromirror devices are also called MOEMS (Micro Electro-Optical-Mechanical Systems). MEMS micromirror arrays are often the key components used in spatial light modulators (SLMs). These devices are used in high-definition display systems as well as optical switching networks. Spatial light modulators that modulate (redirect) light to create high-definition imaging from digital signals. These devices are used in projection displays include digital light processing (DLP) with arrays of micro mirrors and grating light valve (GLV) with silicon nitride ribbons that can be actuated.

A major application for MEMS is as sensors. Primary MEMS sensors are pressure sensors, chemical sensors, and inertial sensors (accelerometers and gyroscopes), and infrared sensors for temperature measurements.

MEMS sensors can be used in combinations with other sensors for multi-sensing applications. For example, a MEMS for laboratory testing (lab-on-a-chip) can be designed with sensors to measure the flow rate of a liquid sample and at the same time identify any contaminates within the sample.

In addition to sensors, MEMS consist of pumping devices, gear trains, movable mirrors, miniature robots, tweezers, tools and lasers. These devices have found numerous applications with various fields such as biomedical, optical, wireless networks, aerospace, and consumer products.

MEMS and IoT

The Internet-of-Things (IoT) and the adoption of smart connected devices at a huge scale currently is the major driver for MEMS products.

IoT devices have the capability to connect with the internet and they feature technical features like MEMS sensors and actuators, software, and power supply. Look at watches: Traditional manual watches were used to display the time. Period. Modern IoT smartwatches allow you to measure heartbeat rate, blood pressure, calorie count, steps walked etc. and transmit this data the cloud.

MEMS and nanotechnology

Nanotechnology research is dependent on MEMS devices. For instance, scanning tunneling-tip microscopy (STM) and atomic force microscopy (AFM) are devices that wouldn’t exist without MEMS components. In fact, a variety of MEMS technologies are required in order to interface with the nanoscale domain.

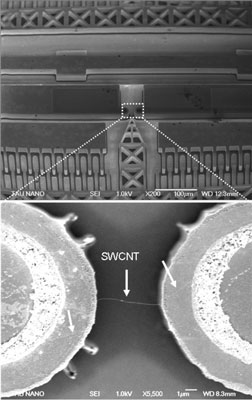

The logical continuation of further miniaturization will lead from MEMS to NEMS – nanoelectromechanical systems. Here, feature elements are well below the micron range in the realm of the nanoscale.

One example, again very relevant for IoT devices is the size of antennas. Tiny antennas also have big implications in the biomedical field. For example, they could lead to better bio-injectible, bio-implantable, or even bio-ingestible devices that monitor health.

To further miniaturize antennas, researcher managed to design and fabricate acoustically actuated ultra-compact NEMS magnetoelectric antennas. Instead of designing antennas at the electromagnetic wave resonance – so they receive and transmit electromagnetic waves - they tailored the antennas to acoustic resonance. Acoustic resonance waves are roughly 10 thousand times smaller than electromagnetic waves. This translates to an antenna that's one or two orders of magnitude smaller than even the most compact antennas available today.

Constructing electromechanical building blocks out of nanomaterials such as carbon nanotubes are a fundamental unit process for manufacturing NEMS with sophisticated architectures and to drive several nanoscale transduction applications such as GHz-oscillators, shuttles, memories, syringes and actuators. have demonstrated exceptionally high thermal conductivity, eventually exhibiting a property known as ballistic conduction. This makes them ideal candidates for highly integrated NEMS.

Frequently Asked Questions (FAQs) about MEMS

What is MEMS technology?

MEMS, or Microelectromechanical Systems, are extremely small devices that incorporate mechanical, electrical, and frequently optical components on a single microchip. These devices perform a wide array of functions, from sensing and actuating to data processing and communication. They are mechanical sensors and actuators that are fabricated using micromachining batch technologies, similar to those used for integrated circuits.

What are some examples of MEMS applications?

MEMS technology has found applications across various industries, leading to improved performance and innovative solutions. For example, MEMS are used as accelerometers in modern automobile airbags where they sense rapid deceleration and, if the force is beyond a programmed threshold, initiate the inflation of the airbag. Additionally, every modern automobile and smartphone is equipped with dozens of MEMS sensors and actuators – accelerometers, gyroscopes, compass, motion sensor, pressure sensors, proximity sensor, image sensors, micro-mirrors, and more. The size of today's smartphones would be impossible without the use of numerous MEMS devices.

What are the key components of MEMS devices?

MEMS devices consist of a combination of mechanical (levers, springs, membranes, combs, channels) and electrical (resistors, capacitors, inductors, etc.) components working as sensors or actuators. At a more general level, they consist of four elements: mechanical microstructures, microsensors, micro-actuators, and micro-electronics, all integrated onto the same chip. MEMS can act as sensors, receiving information from their environment and providing an electrical output signal, or as actuators, devices that convert an electrical signal into an action as required by a decision from the control system.

How are MEMS manufactured?

The fabrication of MEMS uses some of the same processes and tools used to fabricate integrated circuits, such as deposition, photolithography, etching, etc. However, MEMS technology has altered or enhanced some of these techniques, as well as added new processes, to build mechanical devices such as microfluidic channels, gears, cantilevers, micro motors, comb drives, and gyroscopes. These adopted techniques for MEMS fabrication are also called micromachining, which includes bulk micromachining, surface micromachining, and high-aspect-ratio micromachining (HARM).

What materials are used in MEMS?

The most common material used in MEMS is silicon, due to its mechanical properties and the well-established manufacturing processes for it. However, other materials such as polymers, metals, and ceramics can also be used.

What are the challenges in MEMS design and fabrication?

MEMS design and fabrication involves numerous challenges, including miniaturization, integration of mechanical and electronic components, material selection, manufacturing process control, and reliability.

What are some applications of MEMS?

MEMS are used in a wide variety of applications, including but not limited to: accelerometers in cars for airbag deployment, gyroscopes in smartphones for motion sensing, microphones for sound detection, and sensors in medical devices.

What is the difference between MEMS and nanotechnology?

While both MEMS and nanotechnology involve working at small scales, they operate at different size ranges. MEMS typically operate at the micrometer scale (one millionth of a meter), while nanotechnology operates at the nanometer scale (one billionth of a meter).

What is the difference between MEMS and NEMS?

NEMS stands for Nano-Electro-Mechanical Systems and the primary difference to MEMS lies in their scale. NEMS function at the nanometer scale (one billionth of a meter), which is 1000 times smaller than MEMS. They provide similar functionality to MEMS but their smaller size can lead to improved performance in certain areas, such as achieving higher frequencies, which is beneficial for applications like resonators and sensors. However, due to their smaller size, NEMS are more challenging to manufacture.

How do MEMS sensors work?

MEMS sensors work by converting a measured mechanical signal into an electrical signal. For example, a MEMS accelerometer measures the force of acceleration and converts it into an electrical signal that can be read by a microcontroller.

What is the lifespan of MEMS devices?

The lifespan of MEMS devices depends on a variety of factors, including the specific device, its application, and the conditions under which it is used. However, many MEMS devices are designed to last for many years.

How reliable are MEMS devices?

The reliability of MEMS devices can be quite high, but it depends on a variety of factors including the design, materials, manufacturing processes, and usage conditions. Reliability is a key focus area in MEMS research and development.

What is the future of MEMS technology?

The future of MEMS technology is promising, with ongoing research and development in areas like miniaturization, integration with other technologies, and new applications. Potential future developments include more widespread use in medical devices, integration with nanotechnology, and the development of more complex and sophisticated MEMS devices.

How has MEMS technology evolved over time?

Starting in the 1960s, MEMS began to transition from research laboratories into everyday products. The first batch fabricated surface micromachined MEMS device, called the resonant gate transistor, was developed in 1964. By the mid-1990s, MEMS components started appearing in numerous commercial products and applications, including force sensors used to control brake deployment in vehicles, blood pressure sensors, inkjet printer heads, miniature analytical instruments, fiber-optic network components, and more. Today, every modern automobile and smartphone is equipped with dozens of MEMS sensors and actuators.