Liquid Crystal Display Technology Explained

Definition:Liquid Crystal Display (LCD) technology is a widely used type of flat-panel display that leverages the light-modulating properties of liquid crystals. LCDs are prevalent in televisions, computer monitors, and smartphones, offering advantages such as energy efficiency and slim profiles. This article explores the definition, operation principles, key components, advantages, limitations, and applications of LCD technology.

Definition and Principle of Operation

LCD technology utilizes the light-modulating properties of liquid crystals combined with polarizers. These crystals do not emit light directly but use a backlight or reflector to produce images in color or monochrome. Liquid crystals are substances that exhibit properties between those of conventional liquids and solid crystals, allowing them to change orientation when exposed to electric fields. This change in orientation affects the light's ability to pass through the liquid crystal layer, enabling the display to produce images.

How do Liquid Crystal Displays Work?

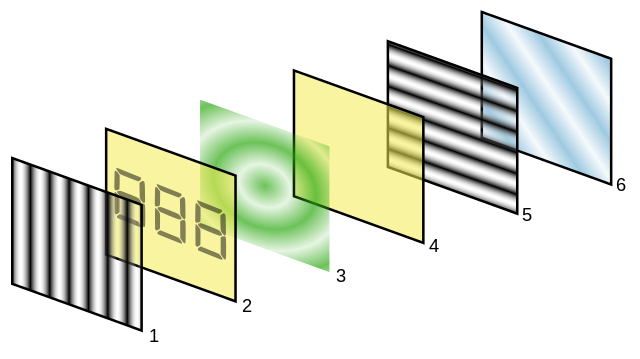

An LCD consists of several layers, including two polarizing filters with perpendicular axes, a layer of liquid crystal molecules, and electrodes that apply the necessary electric field to the crystals. When the electric field is applied, the orientation of the liquid crystal molecules changes, which in turn alters the polarization of the light passing through them. This light then passes through a second polarizer, the orientation of which can either allow the light to pass through or block it, thus producing the image.

The color displays are made possible by dividing the screen into small segments called pixels, each with its own liquid crystal element and a combination of red, green, and blue filters to produce a wide range of colors.

Key Components of an LCD

The primary components of an LCD include:

- Backlight: Provides light for the display. In most modern LCDs, LEDs are used as the light source.

- Liquid Crystal Layer: Comprises rod-shaped molecules that align to form a layer that can modulate light.

- Polarizers: Placed on either side of the liquid crystal layer, these control the direction of light entering and exiting the display.

- Color Filters: Present in color LCDs, these filters define the color of each pixel on the screen.

- Electrodes: Apply the electric field to the liquid crystal layer, controlling the alignment of the molecules.

Advantages of LCD Technology

LCDs offer several advantages, making them popular in a wide range of applications:

- Energy Efficiency: LCDs are more energy-efficient compared to CRT and plasma displays, leading to lower power consumption.

- Compact and Lightweight: The slim profile and light weight of LCDs make them ideal for portable devices and wall-mounted screens.

- High Resolution: Capable of displaying high-resolution images, making them suitable for a wide range of multimedia applications.

- Low Eye Strain: LCDs produce less flicker than CRT displays, reducing eye strain over prolonged use.

Limitations of LCD Technology

Despite its advantages, LCD technology has limitations:

- Viewing Angles: Image quality can degrade at extreme viewing angles.

- Response Time: Some LCDs may exhibit slower response times, affecting the display of fast-moving images.

- Contrast Ratio: LCDs generally have lower contrast ratios compared to some other display technologies, affecting their ability to display deep blacks.

Applications of LCD Technology

LCDs are used in a variety of devices, including:

- Consumer Electronics: Televisions, computer monitors, laptops, and smartphones.

- Automotive Displays: Instrument clusters and navigation systems.

- Industrial Equipment: Control panels and readout displays.

- Public Information Displays: Airport flight information, digital signage, and advertising displays.

LCDs vs. OLEDs: The Fundamental Difference

While both LCD and OLED technologies are used in flat-panel displays, they operate on fundamentally different principles.

- LCDs (Liquid Crystal Displays): LCDs use a backlight to illuminate liquid crystals, which then manipulate the light to create an image. The liquid crystals themselves do not produce light.

- OLEDs (Organic Light-Emitting Diode Displays): OLEDs utilize organic (carbon-based) materials that emit their own light when an electric current is applied. This eliminates the need for a separate backlight.

Key Implications of this Difference:

- Thickness and Flexibility: OLED displays can be made thinner and more flexible than LCDs since they don't require a backlight.

- Contrast and Black Levels: OLEDs can achieve true blacks by turning off individual pixels, resulting in superior contrast ratios compared to LCDs.

- Power Consumption: OLEDs can be more power-efficient, especially when displaying darker images, as pixels that are black do not consume power.

- Cost and Lifespan: LCD technology is generally more mature and affordable, while OLED displays may be more expensive and have a slightly shorter lifespan in some cases.

Recent Technological Advancements in LCD Technology

Technological advancements continue to enhance the capabilities of LCDs, including improvements in energy efficiency, resolution, and flexibility. Innovations such as quantum dots and advanced IPS (In-Plane Switching) technology have led to better color accuracy and wider viewing angles. Additionally, the development of flexible LCD panels has opened up new possibilities for wearable devices and curved displays.

Environmental Impact and Sustainability

The production and disposal of LCDs raise environmental concerns, including the use of hazardous materials and energy consumption. Efforts are underway to develop more sustainable manufacturing processes and recycling methods to mitigate these impacts.

Further Reading

Light: Science & Applications , Liquid crystal display and organic light-emitting diode display: present status and future perspectives