Optical Profilometry

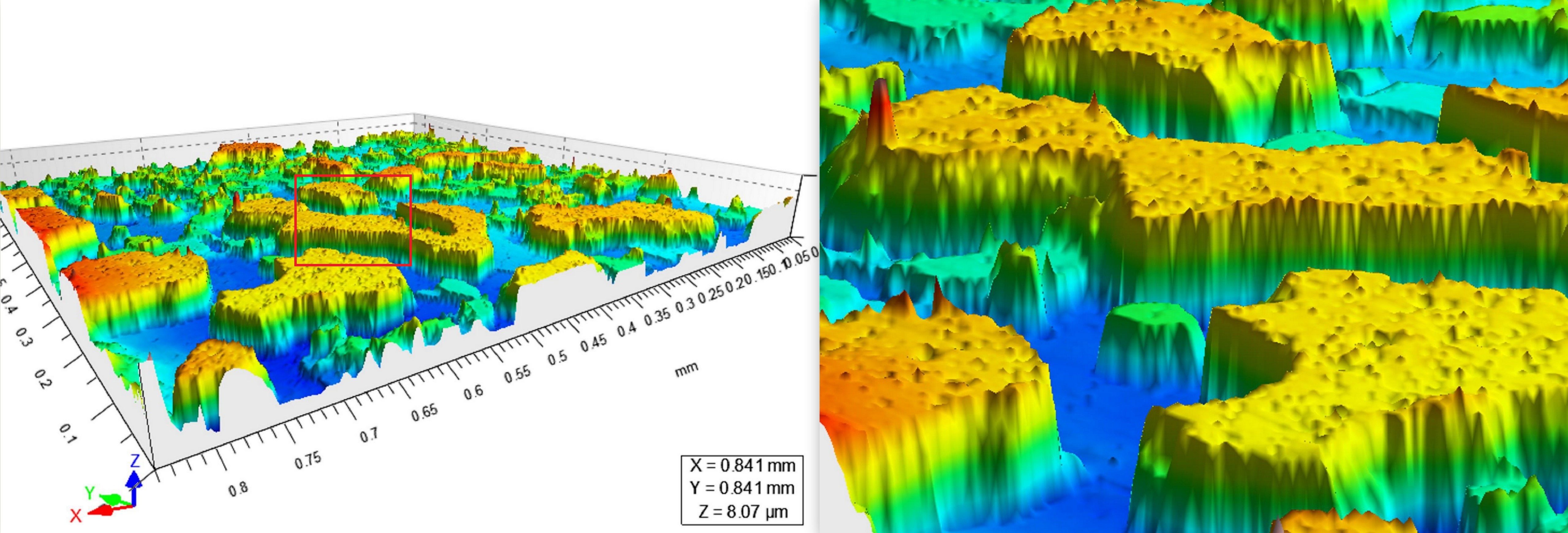

Definition: Optical Profilometry is a non-contact measurement technique used to obtain the topography of a surface, mapping its features with high precision across various scales

Principle of Operation

Optical Profilometry employs light to measure surface contours and roughness by analyzing the interaction between light waves and the surface under examination. It utilizes various principles such as interference, reflectance, or shadowing to capture the three-dimensional topography of the surface. Techniques like white light interferometry (WLI) and confocal microscopy are common, each providing high-resolution surface measurements. These methods involve directing a light source onto the surface and analyzing the reflected light to reconstruct the surface's profile, allowing for the measurement of features ranging from nanometers to millimeters in height.

For those delving deeper, distinguishing between techniques such as coherence scanning interferometry (CSI) and confocal microscopy is essential. CSI, or white light interferometry, excels in measuring surface features with varied heights due to its interference-based approach, offering nanometer resolution suitable for rough surfaces. Confocal microscopy, utilizing a pinpoint laser beam and spatial filtering – a technique that isolates and focuses on specific depths of the surface while ignoring out-of-focus light – provides high resolution and depth control, ideal for detailed surface analysis of reflective or transparent materials. This differentiation highlights the adaptability of optical profilometry to diverse measurement needs and surface characteristics.

Key Features of Optical Profilometry

- Non-Contact Measurement: As a non-destructive technique, it is ideal for delicate or soft surfaces that could be damaged by contact methods.

- High Resolution: Capable of capturing surface details at the nanometer scale, making it suitable for analysis of very fine features.

- Versatility: Applicable to a wide range of materials, including metals, polymers, ceramics, and composites.

- Quantitative Analysis: Provides precise measurements of surface roughness, texture, and other topographical features.

Limitations

While offering detailed surface analysis, Optical Profilometry has its limitations:

- Surface Reflectivity: Highly reflective or transparent materials can pose challenges, potentially requiring special preparation to reduce measurement errors.

- Limited Penetration Depth: Being a surface technique, it cannot measure features that are not directly exposed to the surface.

- Field of View: The measurable area in a single image can be limited, requiring stitching of multiple images for larger surfaces.

Applications

Optical Profilometry is used in numerous fields for surface characterization, including:

- Materials Science: For studying surface morphology, wear, and corrosion.

- Semiconductor Industry: In the inspection of wafer surfaces and the measurement of micro and nano-scale features on chips.

- Manufacturing Quality Control: For ensuring the quality of precision-engineered components and surfaces.

- Biomedical Engineering: In assessing the roughness of implants and other medical devices to optimize their interaction with biological tissues.