Resistive Random-Access Memory (ReRAM): Principles, Materials, and Applications

What is ReRAM?

ReRAM, or Resistive Random-Access Memory, is an emerging non-volatile memory technology that holds promise for the next generation of data storage devices. It is based on the principle of changing the resistance of a material by applying electrical pulses, allowing for high-density, low-power, and fast memory operations.

How ReRAM Works

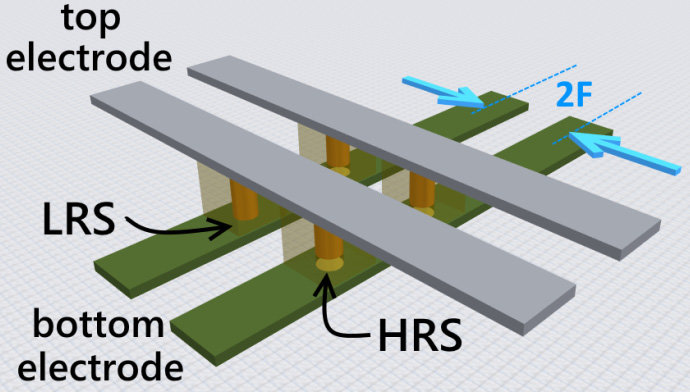

ReRAM operates by exploiting the resistance switching phenomenon in certain materials, typically metal oxides. The basic structure of a ReRAM cell consists of a metal-insulator-metal (MIM) stack, where the insulator layer is sandwiched between two metal electrodes. By applying electrical pulses, the resistance of the insulator layer can be switched between a high-resistance state (HRS) and a low-resistance state (LRS), representing binary data.

The resistance switching in ReRAM can be attributed to various mechanisms, such as:

- Formation and rupture of conductive filaments: In some ReRAM materials, the application of an electrical field leads to the formation of conductive filaments through the insulator layer, resulting in a low-resistance state. Reversing the polarity of the applied field can rupture these filaments, returning the cell to a high-resistance state.

- Valence change mechanism: In certain metal oxides, the resistance switching is caused by the migration of oxygen vacancies or ions under an applied electric field. This changes the electronic structure and conductivity of the material, allowing for a reversible transition between high and low resistance states.

Comparison with Existing Memory Technologies

ReRAM offers several advantages over conventional memory technologies like DRAM, NAND flash, and NOR flash. The following table compares the key performance metrics of these memory technologies:

| Memory Type | Non-Volatility | Write Speed | Read Speed | Endurance (cycles) | Retention | Scalability |

|---|---|---|---|---|---|---|

| ReRAM | Yes | ~10 ns | ~10 ns | 106 - 1012 | >10 years | High |

| DRAM | No | ~10 ns | ~10 ns | ∞ | ~64 ms | Moderate |

| NAND Flash | Yes | ~100 μs | ~25 μs | 104 - 105 | >10 years | High |

| NOR Flash | Yes | ~1 μs | ~10 ns | 105 - 106 | >10 years | Low |

As evident from the table, ReRAM offers several advantages over existing memory technologies:

- Non-volatility: Unlike DRAM, ReRAM retains data even when the power is turned off, making it suitable for long-term storage and low-power applications.

- Fast read and write speeds: ReRAM can achieve read and write speeds comparable to DRAM and much faster than NAND and NOR flash.

- High endurance: ReRAM can withstand a large number of write cycles, typically in the range of 106 to 1012, which is significantly higher than NAND and NOR flash.

- Excellent scalability: ReRAM can be scaled down to nanometer dimensions, enabling high-density memory arrays and potential 3D integration.

These advantages make ReRAM a promising candidate for next-generation non-volatile memory applications, offering a combination of high performance, low power consumption, and high scalability.

ReRAM Materials

Various materials have been explored for ReRAM applications, including transition metal oxides, perovskites, and chalcogenides. Some of the most promising ReRAM materials include:

- Hafnium oxide (HfO2): HfO2 is a widely studied ReRAM material due to its compatibility with CMOS technology and excellent scalability. It exhibits fast switching speeds and low power consumption.

- Tantalum oxide (Ta2O5): Ta2O5 has shown promising results for ReRAM applications, with good endurance and retention properties. It can be easily integrated with existing semiconductor manufacturing processes.

- Titanium oxide (TiO2): TiO2 is another well-studied ReRAM material, known for its high resistance ratio between HRS and LRS states. It has been demonstrated in both planar and 3D architectures.

Researchers are also exploring novel materials and device structures to further enhance the performance and reliability of ReRAM devices.

Applications of ReRAM

ReRAM has potential applications in various domains, including:

- Non-volatile memory: ReRAM can replace or complement existing non-volatile memory technologies like NAND flash, offering higher density, faster access times, and lower power consumption.

- Neuromorphic computing: The resistance switching behavior of ReRAM closely resembles the synaptic plasticity in biological neural networks. This makes ReRAM a promising candidate for implementing artificial synapses in neuromorphic computing systems, enabling energy-efficient and scalable brain-inspired computing.

- In-memory computing: ReRAM can be used to perform computation directly within the memory array, eliminating the need for data transfer between memory and processing units. This in-memory computing paradigm can significantly improve the efficiency and speed of data-intensive applications.

Challenges and Future Perspectives

Despite the promising potential of ReRAM, several challenges need to be addressed for its widespread adoption. One of the main challenges is the variability and reliability of ReRAM devices. The resistance switching behavior can be affected by various factors, such as the material composition, device structure, and operating conditions. Ensuring consistent and reliable performance across a large array of ReRAM cells remains a significant hurdle.

Future research efforts in ReRAM will focus on improving the device reliability, scalability, and integration with existing semiconductor manufacturing processes. The development of novel materials and device architectures, along with advanced characterization techniques, will play a crucial role in overcoming the current limitations of ReRAM technology.

As ReRAM continues to mature, it is expected to find applications in a wide range of domains, from high-density data storage to energy-efficient computing and neuromorphic systems. The integration of ReRAM with other emerging technologies, such as 3D integration and advanced packaging, will further expand its potential and drive the development of next-generation memory and computing devices.

Further Reading

Nanoscale Research Letters, Resistive Random Access Memory (RRAM): an Overview of Materials, Switching Mechanism, Performance, Multilevel Cell (mlc) Storage, Modeling, and Applications

Journal of The Electrochemical Society, Resistance Switching Behaviors of Hafnium Oxide Films Grown by MOCVD for Nonvolatile Memory Applications