| Posted: Jul 22, 2014 |

Microscopy charges ahead

|

|

(Nanowerk News) Polarization charges in ferroelectric materials are screened by equal amounts of surface charges with opposite polarity under ambient conditions. Researchers from the Center for Nanoscale Materials, Argonne's Nanoscience & Technology and Materials Science divisions, and Tohoku University have shown ("Charge gradient microscopy") that scraping, collecting, and quantifying surface screen charges reveals the underlying polarization domain structure at high speed, a technique dubbed charge gradient microscopy (CGM).

|

|

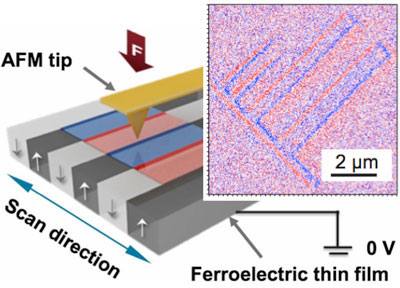

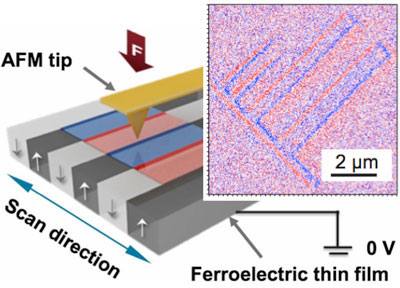

| Schematic of CGM and (right) trace and retrace CGM images of artificially decorated ribbon-shaped domains in 85-nm-thick LiTaO3 film. The domains were poled by 6 V to the bottom electrode by using a platinum tip at a scan frequency of 40 Hz.

|

|

CGM uses the tip of a conventional atomic force microscopy (AFM) to scrape and collect the surface screen charges. Current was collected from a grounded CGM probe while scanning a periodically poled lithium niobate single crystal and a single crystal LiTaO3 thin film. CGM may be used to study the complex among between surface screen charges, electric dipole moments, and domain dynamics of ferroelectric materials.

|

|

Ferroelectric materials — substances in which there is a slight and reversible shift of positive and negative charges — have surfaces that are coated with electrical charges like roads covered in snow. Accumulations can obscure lane markings, making everyone unsure in which direction traffic should flow. In the case of ferroelectrics, these accumulations are other charges that "screen" the true polarization of different regions of the material. Ferroelectric materials are of special interest to researchers as a potential new form of computer memory and for sensor technologies. CGM was developed to see this true polarization quickly and efficiently.

|

|

Current signals at the domains and domain walls were observed to originate from the displacement current and the relocation or removal of surface charges, which enabled visualization of the ferroelectric domains at a scan frequency above 78 Hz over 10 µm. The scraped charge, measured as a current that scales with scraping rate, induces a charge gradient that leads to the immediate relocation or refill of the screen charges from the vicinity of the probe. As such, CGM may be applied to probe the complex dynamics of domain nucleation and growth induced by a biased tip in the absence of surface screen charges.

|

|

Previous efforts in this arena had focused on using piezoresponse force microscopy (PFM). In this technique, an applied voltage causes a small displacement of atoms in the material, generating a noticeable mechanical effect, or vibration. PFM, however, is slow and requires sophisticated equipment to measure tiny motions.

|