| Posted: Oct 28, 2014 |

A new cheap and efficient method to improve SERS

|

|

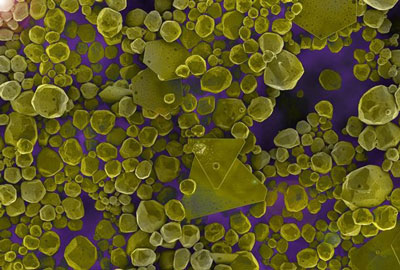

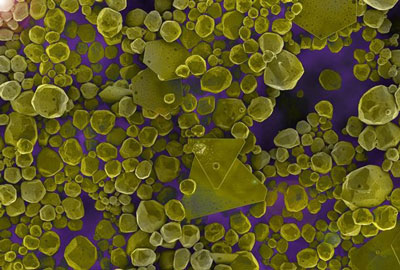

(Nanowerk News) Materials Today´s cover highlights the research work ("Reliable and cheap SERS active substrates") developed by CiQUS researchers, which developed a new method to overcome the problems of Surface Enhanced Raman Spectroscopy (SERS), an ultra-sensitive analytical technique able to detect chemicals in very low concentration, even up to single molecules, and also to retrieve structural information. SERS high sensitivity comes from the interaction of molecules with highly localized and intense fields called plasmons, caused by interaction of light with a metal surface, usually nanostuctured. Research results allow to cut production costs of substrates, and also tackle the lack of reproducibility usually associated to this technique.

|

|

|

The main contribution of this work is the fabrication of new substrates made of polymer and aluminium with a regular pattern. These new substrates have demonstrated a comparable, or even better signal enhancement, than that obtained with the few available and expensive commercial ones. Normal substrates are made of metal nanoparticles deposited on a flat support. The randomness of size, shape and distribution of these particles cause the low reproducibility of these conventional substrates. A way to overcome this problem is to use a micro or nano-structured substrate with a regular pattern. Conventional approaches, based on silicon structured by lithography techniques, is quite expensive and leave abundant residues.

|

|

In the current work, the authors took advantage of an unconventional replication technique which use a mold and UV light to hardened a polymer with any possible shape. The process last just a few seconds and after release the elastomeric replica with the micro and nanostructures, it is covered with a thin film of metal by a process of physical metal vapour deposition. A new polymer called “liquid Teflon” allows the fabrication of really tiny details in the sub-10nm range, and expand design flexibility. Several metals -like the usual gold and silver- were tested with good results, but they also tested aluminium with even better results. This is relevant because aluminium has been usually rejected as SERS substrate due to its easy oxidation, what it is true; but the oxidation process is so fast, and the crust so impermeable, that the process stops readily, leaving an oxide layer of only a few nanometers (2-3nm) that explain that the substrate still works properly. What is more, the oxide layer protect the surface, and stabilize the substrate for more time.

|

|

This work was developed at CiQUS by the PhD student Manuel Gómez at Massimo Lazzari´s group. They obtained the micrographs an Raman spectra at CACTUS.

|

|

This new kind of SERS substrates, made of polymer and aluminium, are able to improve the results and the reproducibility of SERS results and simplify the measurement process, making the technique easy to use in any laboratory.

|

|

Technical note

|

|

Raman spectroscopy gives low intensity spectra, but the SERS effect is about amplifying Raman signals of molecules by several orders of magnitude due to local field enhancements called “hot-spots”. To profit from these local field enhancements, the molecules must be very close to the metal surface (around 10nm maximum). Random distribution of metal particles and shapes gives low reproducibility.

|

|

However, in this work the researchers have proposed a completely regular pattern, a 2.5D photonic structure. Such kind of structures are usually produced by means of expensive and polluting processes but here the proposed fabrication process exchange the conventional top-down protocol by a bottom-up one, where a photopolymer (a perfluoropolyether derivate) is used to fabricate the micro and nano-patterns by ultraviolet nano-imprint lithography (UV-NIL), an eco-friendly technique without residues and very low power consumption. This technique is fast and it takes just a few seconds to obtain the structured substrate by crosslinking of the polymer chains. The structured polymer is covered with a thin metallic layer, the plasmonic layer, usually gold or silver.

|

|

The choice of aluminium as active metal is another novelty of this work, since this metal has often been rejected as SERS substrate because its easy oxidation and inadequate plasmon wavelength. Experimental evidence and theoretical calculations show that what had been considered a problem it is really an advantage, since the Al2O3 passivation layer is so thin that it still allow the propagation of plasmon and so hard and impermeable that the oxidation process stops readily after oxide layer formation. This passivation phenomenon would explain the temporal and environmental stability of these substrates.

|