| Posted: Jun 24, 2015 |

Setting the standard for graphene

|

|

(Nanowerk News) The superlative properties of graphene- the world's thinnest material, ultra-strong, highly conductive, and many more- are becoming increasingly well known. However, as a recent estimate suggested there are more than 600 different types of graphene, commercial organisations looking to work with the material can struggle to know where to start.

|

|

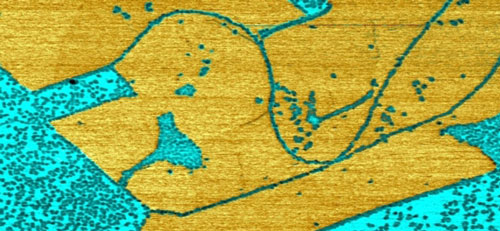

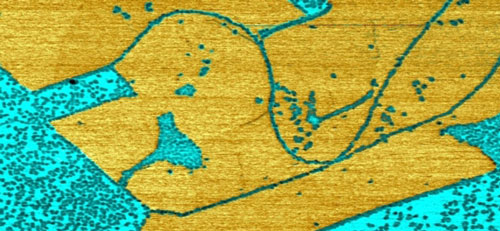

| Adhesion map of epitaxial graphene on silicon carbide.

|

|

To address this problem, The University of Manchester and the National Physical Laboratory (NPL) have joined forces by holding the Graphene UK Standardisation Workshop at the National Graphene Institute (NGI). Key figures from the graphene supply chain worked together to provide input into a White Paper and discuss next steps for setting up a graphene centre of excellence focussed on characterisation, metrology and standardisation. This will be based primarily at the NGI and NPL, but utilising key capability from other institutes and industries.

|

|

Standardisation is crucial for the commercialisation of any emerging technology, providing a guide for organisations that ensure the quality and safety of materials, components and products for both the supply chain manufacturers and the end consumer. Graphene can vary in its number of layers, in the way it is produced and in terms of quality, with some applications requiring a higher quality than others.

|

|

"There are different types of graphene and different ways of producing it," JT Janssen, NPL Fellow in Quantum Electrical Metrology, told 50 delegates at the National Graphene Institute (NGI). "You have to make sure you are speaking the same language." This common language of graphene is what the White Paper hopes to establish.

|

|

The workshop engaged with government funding agencies, graphene manufacturers, suppliers, researchers and SMEs to gather as full a picture as possible of the challenges faced by a lack of defined criteria. As Janssen explained in his presentation, before any standards can be established, the customer needs to work out what application is being proposed, what properties of graphene they are looking to exploit, and how performance can be measured. It is a lengthy and complicated task.

|

|

Tom Taylor, Director of New Business at the Centre for Process Innovation (CPI), said: "It has been really good to gather this group together and get a collective UK perspective. CPI shares a common good with the NGI and this community to help bring graphene products to market. We are delighted to be working with The University of Manchester and NPL on this common challenge."

|

|

James Baker, Graphene Business Director at The University of Manchester, told the Workshop that partnership is the key to delivering a standard for graphene. He said: "This event is to bring together the graphene community to address this significant challenge. The partnership between the University and NPL is the best way to achieve this, and is a very important step in the commercialisation of graphene."

|

|

The Graphene UK Standardisation Workshop is part of a week of industry-focussed events at the newly opened National Graphene Institute. The £61M building, which opened in March 2015, will see academics and commercial organisations working side by side to produce graphene applications of the future.

|

|

All this week, companies have been attending a series of Industry Workshops to find out how they can partner with the NGI and work with graphene. The Workshops have been organised alongside Graphene Week 2015, the leading international academic conference held at the University.

|

|

Following input from the graphene community today, the White Paper will be presented to Government to lobby for future funding to establish a graphene standards centre.

|