| Posted: Jun 02, 2016 |

Researchers mimic butterfly wing nanostructures for compact new technology

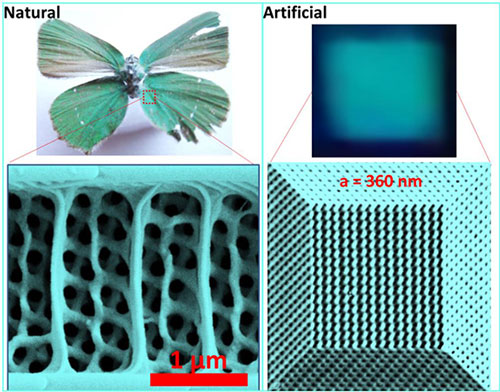

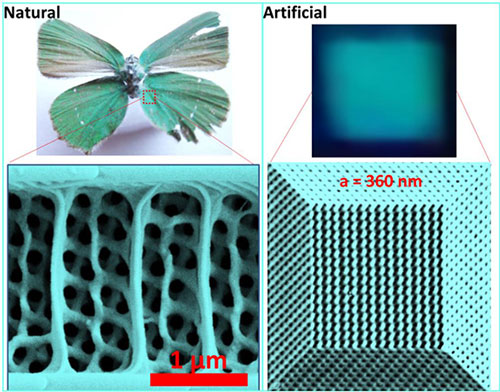

(Nanowerk News) Inspired by the intricate structure of a butterfly wing, Swinburne researchers have developed a technique that could be used to make more brilliant computer screens (Science Advances, "Biomimetic gyroid nanostructures exceeding their natural origins").

|

|

| Nanostructures on the wings of the Callophrys Rubi or Green Hairstreak butterfly have inspired the design of an artificial material that could be used in photonics and optics technologies.

|

|

The researchers used a special printing technique to create tiny structures similar to those found in the wings of the Callophrys Rubi butterfly, also known as the Green Hairstreak.

|

|

In some iridescent butterfly wings, such as the Green Hairstreak, the wing is made up of a pattern of intertwining and curved surfaces, known as a gyroid structure. This gyroid structure has amazing properties when it comes to its interactions with light.

|

|

The researchers used two-beams of light to print at a super-resolution, creating gyroid structures that are three-dimensional and mechanically strong.

|

|

| Comparison of natural gyroid structure with artificial structure.

|

|

Lead author Dr Zongsong Gan from Swinburne’s Centre for Micro-Photonics says that materials made from these artificial gyroids should respond to light at ultrafast speeds making them ideal for high-speed switches.

|

|

He says the technique has two significant advantages.

|

|

"The first is that it has improved resolution and the second is that the materials fabricated with this technique have better mechanical strength.

|

|

"These new gyroid structures could help make more compact light based electronics because, thanks to their smaller size, larger numbers of devices can be integrated onto a single chip.

|

|

“However, for three-dimensional devices, smaller and more compact also means there is a higher risk of structure collapse because of weaker mechanical strength.

|

|

"Our fabrication technique allows us to make stronger architectures to overcome this problem," Dr Gan says.

|