| Posted: Jun 21, 2016 |

New bimetallic alloy nanoparticles for printed electronic circuits

(Nanowerk News) “Printed electronics” has the potential to enable low-cost fabrication of electronics on flexible or curved surfaces, which will lead to the use of electronics in more varied applications. We will be able to fabricate homemade mobile phones or smart watches using a printer in the future. However, the low performance and high cost of current conductive inks have been limiting the advancement of printed electronics.

|

|

Now, Go Kawamura from Toyohashi University of Technology and his collaborators at Duke University have found a way to produce new copper alloy nanoparticles, which can be used as the main component of affordable conductive inks with high oxidation resistance (Scientific Reports, "Production of oxidation-resistant Cu-based nanoparticles by wire explosion").

|

|

The researchers electrically exploded alloy or twisted metal wires in water with a mild reducing agent (Vitamin C) in order to produce the nanoparticles. The reduction in conductivity was subsequently measured under harsh conditions (high temperature and high humidity).

|

|

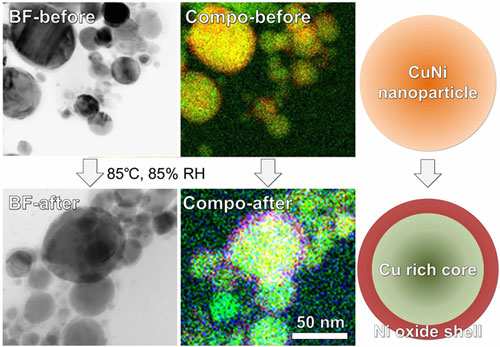

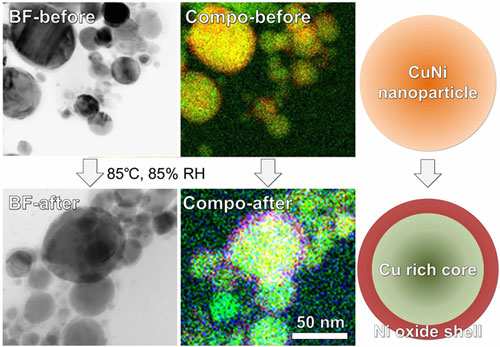

| Bright-field (BF) scanning transmission electron microscope images, composed (Compo) elemental mappings, and illustrations of Cu alloy nanoparticles containing 30% Ni before and after oxidation treatment at 85 °C and 85% relative humidity. (click on image to enlarge)

|

|

"We had been working on developing a ‘wire explosion’ method to produce novel metal nanoparticles. Then, we found that some of the produced copper alloy nanoparticles possessed both high oxidation resistance and low electrical resistance," explains Assistant Professor Go Kawamura. "Moreover, the nanoparticles have the advantage of being inexpensive because the production process is very economical and environmentally friendly."

|

|

As a result, copper nanoparticles alloyed with 1% Sn, 5% Ag, 5% Ni, or 30% Ni had electrical conductivities similar to that of copper; however, unlike copper, the nanoparticles remained conductive after 24 h at 85 °C and 85% relative humidity.

|

|

With further improvement of the electrical conductivity and oxidation resistance, copper alloy nanoparticles prepared by wire explosion could be used for the production of high-performance affordable conductive inks, which will contribute to the advancement of printed electronics.

|

|

The researchers also hope this work will encourage further study combining wire explosion with chemical modification of the explosion medium to control the composition and surface chemistry of nanoparticles.

|