| Posted: Aug 04, 2016 |

High accuracy measurements to meet manufacturing needs

(Nanowerk News) The advanced technologies designed by researchers working on the SURFUND project go beyond the current state-of-the-art techniques in metrology, the science of measurements applied to manufacturing and other industrial processes. These novel measurement tools could have a large application potential in optics, aerospace, automotive, precision engineering, electronics and biotech industry and they have already attracted the attention of several companies working in these fields.The innovations generated by this ERC project could bring significant economic benefits to Europe.

|

|

| Dispersed reference interferometer (DRI). (Image: University of Huddersfield)

|

|

In recent years, freeform surfaces are being manufactured more frequently and are being used in a wide variety of products such as optical systems, energy-efficient jet engines, human joint implants, solar panels. As freeform surfaces - also called complex surfaces - have often no symmetries at all, it is complicated to ensure good quality during their manufacturing. With the requirements imposed by continuous technological development, the need to make and measure these surfaces to a very high precision becomes more and more important.

|

|

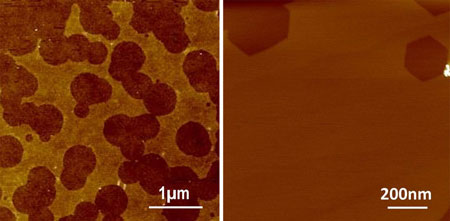

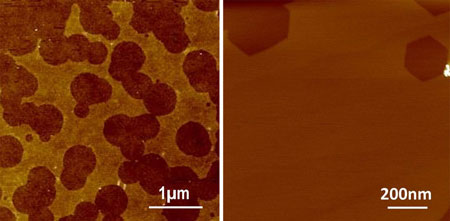

Prof. Xiangqian Jiang took on this challenge and, using mathematical models, explored new basics and principles for measuring and characterizing non-planar surfaces at nano-precision level. With her multidisciplinary team, she succeeded in designing nanometer-accurate instruments which possess noncontact and high speed qualities, are easy to use and can be produced at affordable costs, paving the way to the 21st century advanced surface measurements.

|

|

Processes, sensors and instruments developed during this ERC project have applications for many products (e.g. flexible photovoltaic cells, flexible/ printable electronics, roll-to-roll flat panel displays, solar concentrators) as well as in the automotive, aerospace, semiconductor, bio-engineering and food packaging sector. These technologies guarantee an optimal performance, reduce manufacturing costs and could help the industry move towards a more environmentally-friendly production (zero waste and carbon neutral production).

|

|

So far, more than ten world-leading companies in these fields in Europe and the USA have expressed their interest in the results of this research led by the University of Huddersfield.

|

|

The technology transfer has already taken place through patents and strong cooperation with industries. To this purpose, Prof. Jiang, supported by an ERC Proof of Concept Grant for the project EMINSTR, launched the technical optimization, product prototype design and technological licensing to finally bring to the market three instruments: the wavelength scanning interferometer (NWSI), the white-light channelled spectrum interferometer (WLCSI), and the dispersed reference interferometer (DRI).

|

|

The momentum generated by the ERC funding led to the creation in 2011 of the Centre for Innovative Manufacturing in Advanced Metrology (UK) of which Prof. Jiang is the director. Building on the results of the SURFUND project, completed in 2015, she is currently pursuing her research to apply the developed technologies to the manufacturing of cells contributing to cell-based therapies and regenerative medicine.

|