| Posted: Aug 31, 2016 |

Development of a Novel Mass analysis technique that can be performed even with an ordinary business card

(Nanowerk News) An ICYS-MANA researcher, Kota Shiba, International Center for Young Scientists (ICYS), National Institute for Materials Science (NIMS), and Genki Yoshikawa, a Group Leader of the Nanomechanical Sensors Group, International Center for Materials Nanoarchitectonics (MANA), NIMS, developed a new mass analysis technique that operates under a completely different principle from that of conventional techniques (Scientific Reports, "Aero-Thermo-Dynamic Mass Analysis").

|

|

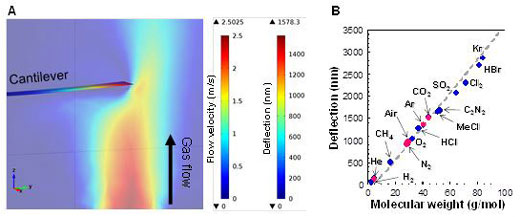

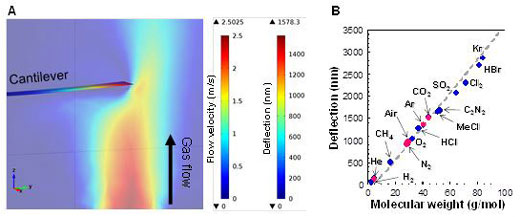

| Figure: A) An example of finite element analysis. A gaseous sample was flowed toward the free end of the micro-cantilever. B) Relationship between molecular weights of various gaseous samples and deflection of the micro-cantilever. Note close agreement between analytical model (dotted gray line), experimental values (red circles), and simulated values by finite element analysis (blue circles).

|

|

The new technique can be performed even with a hand-held paper strip, applying gas flow to the strip at a constant flow rate, causing the strip to deform, and calculating the molecular weight of the applied gas based on the principle that the amount of deformation (deflection) varies according to molecular weight of the applied gas.

|

|

The technique enables users to measure molecular weights of gaseous samples in the air in real time. The principle behind the technique appears to be very simple, but no one had reported it before. This discovery can be a breakthrough for the development of much smaller and inexpensive mass analysis devices than conventional ones.

|

|

Mass analysis is a technique for analyzing molecular weights of samples, and this scientific method drew much public attention when Dr. Koichi Tanaka won a Nobel Prize in 2002. Conventionally, the molecular weight of a sample is measured by first ionizing the molecules through, for example, irradiation of electrons in a vacuum. Then, an electric or magnetic field is applied to these ions and their molecular weights are measured based on the principle that the ions travel in different directions according to their molecular weights.

|

|

As also demonstrated by Dr. Tanaka’s research, this basic principle still remains valid in essence today since the time when the first mass analyzer was constructed in early 20th century. Although the molecular weights of samples can be accurately measured by conventional mass analyzers, it had been difficult to make these devices smaller due to the requirements of vacuum condition and ionization.

|

|

The research team recently discovered a principle unused in conventional mass analysis, and developed a new kind of mass analysis technique based on the principle, which enables users to easily measure the molecular weights of gases in real time without a vacuum condition or ionization. The new principle indicates that when gaseous molecules flow toward a one-end-fixed elastic object, they cause the object to deflect, and the amount of deflection varies depending on the weight of the molecules.

|

|

The team in fact experimentally confirmed that when gases were flowed toward a silicon micro-cantilever and a paper business card, the amount of deflection produced in these objects varied depending on the molecular weights of the applied gases. Figure illustrates that the molecular weights of gaseous samples were determined simply by flowing the gases toward a hand-held business card and measuring its deflection.

|

|

The team also successfully developed an analytical model of the relationship between the amount of deflection and the molecular weight of gases through the combination of basic principles in fluid dynamics, thermodynamics, and structural mechanics. In this manner, the team theoretically proved the validity of the proposed principle. Subsequently, the invented technique was named as “aero-thermo-dynamic mass analysis (AMA).”

|

|

Based on these results, the research team intends to develop mobile mass analysis devices and apply them to various fields including health management, environmental monitoring, and disaster prevention. The team will also promote the use of AMA in the industrial sector through the integration with other techniques, such as gas chromatography, for process management etc.

|