| Posted: Dec 15, 2016 |

Not your typical 'cut glass crystal'

(Nanowerk News) To better move energy in solar cells and other devices, scientists need single, ordered crystals. The single crystals can handle tough environments while transmitting energy and light well. However, conventional manufacturing methods don’t work for all materials.

|

|

Scientists devised the first fabrication method that takes disordered solid glass and turns it into single crystals without melting the glass. The method suppresses multiple small crystals from forming and allows a single crystal seed to grow across the entire line or surface (Scientific Reports, "Demonstration of single crystal growth via solid-solid transformation of a glass").

|

|

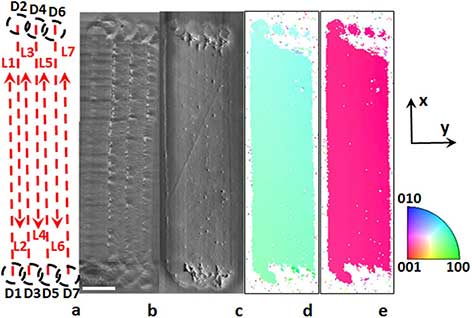

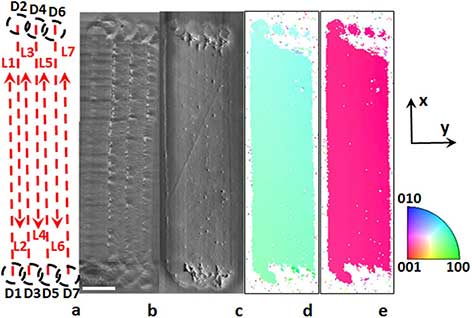

| Scientists at Lehigh University used a laser to make ordered single crystals on a disordered glass surface. In the colorized scanning electron micrograph, the green color letters represent single crystals embedded in glass shown in blue. The width of the single crystal lines is about five micrometers—about the same width as a single strand of silk from a spider’s web. (Image: Dmytro Savytskii, Brian Knorr, Volkmar Dierolf, and Himanshu Jain)

|

|

With this new approach, scientists can fabricate single crystals of compositions that are unstable at the high temperatures used in existing production methods. The team’s process is simple and low cost. It enables fabrication of complex shapes with single crystals. These shapes could enable new materials for solar cell devices or other applications such as superconductors, which offer little or no resistance to electricity.

|

|

Using a focused laser beam, researchers demonstrated for the first time that single crystals could be written into a solid glass matrix as dots, lines, and two-dimensional patterns by locally heating the glass to the crystallization temperature and avoiding melting.

|

|

The simple, low-cost approach allows fabrication of single crystals of novel compositions that decompose, melt incongruently, or undergo phase transformation between the crystallization and melting temperatures. Researchers at Lehigh University hypothesized that they could fabricate a single crystal in glass by establishing only one nucleation point and not allowing other nucleation sites to form.

|

|

They did this by moving a laser at sufficient speeds or by adding a nucleation suppressant to the glass. The researchers chose antimony trisulfide as a test material because it has exceptional pyro-optic properties; however, it has been impractical to obtain from a melt because it loses sulfur when heated in an inert environment or reacts with oxygen in air. By keeping the temperature below the melting temperature, the investigators successfully fabricated single crystal regions on the surface of the glass.

|

|

The new method could enable a wider range of complex materials for microelectronics used in solar cell devices or other high-technology applications such as superconductors.

|