| Posted: Jan 24, 2017 |

New solution for making 2D nanomaterials

(Nanowerk News) Two-dimensional (2D) nanomaterials have been made by dissolving layered materials in liquids, according to a recent publication involving London Centre for Nanotechnology (LCN) resaerch. The liquids can be used to apply the 2D nanomaterials over large areas and at low costs, enabling a variety of important future applications.

|

|

2D nanomaterials, such as graphene, have the potential to revolutionise technology through their remarkable physical properties, but their translation into real world applications has been limited due to the challenges of making and manipulating 2D nanomaterials on an industrial scale.

|

|

The new approach, published in Nature Chemistry ("Ionic solutions of two-dimensional materials"), produced single layers of many 2D nanomaterials in a scalable way. The researchers used the method on a wide variety of materials, including those with semiconductor and thermoelectric properties, to create 2D materials that could be used in solar cells or for turning wasted heat energy into electrical energy, for example.

|

|

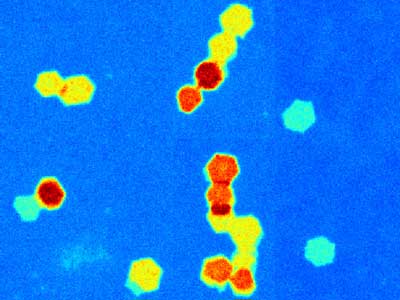

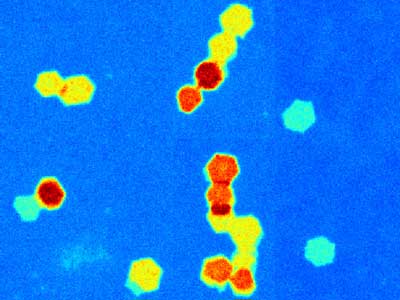

| A laser shines through a solution of still dissolving 2D nanomaterial showing there are particles within the liquid. When a drop of the solution is dried, the still dissolving nanosheets connect into different tiled shapes. When left to fully dissolve, only single layer sheets are found. A single layer nanosheet is blue, a two layer one is yellow, a three layer one is orange and a four layer one is red. (Credit: Patrick Cullen, LCN).

|

|

“2D nanomaterials have outstanding properties and a unique size, which suggests they could be used in everything from computer displays to batteries to smart textiles. Many methods for making and applying 2D nanomaterials are difficult to scale or can damage the material, but we’ve successfully addressed some of these issues. Hopefully our new process will help us realise the potential of 2D nanomaterials in the future,” explained study director Dr Chris Howard.

|

|

For the study, funded by the Royal Academy of Engineering and the Engineering and Physical Sciences Research Council, the scientists inserted positively charged lithium and potassium ions between the layers of different materials including bismuth telluride (Bi2Te3), molybdenum disulphide (MoS2) and titanium disulphide (TiS2), giving each layer a negative charge and creating a ‘layered material salt’.

|

|

These layered material salts were then gently dissolved in selected solvents without using chemical reactions or stirring. This gave solutions of 2D nanomaterial sheets with the same shape as the starting material but with a negative charge.

|

|

The scientists analysed the contents of the solutions using atomic force microscopy and transmission electron microscopy to investigate the structure and thickness of the 2D nanomaterials. They found that the layered materials dissolved into tiny sheets of clean, undamaged, single layers, isolated in solutions.

|

|

The team from UCL, University of Bristol, Cambridge Graphene Centre and École Polytechnique Fédérale de Lausanne, were able to demonstrate that even the 2D nanomaterial sheets, comprising millions of atoms, made stable solutions rather than suspensions.

|

|

“We didn’t expect such a range of 2D nanomaterials to form a solution when we simply added the solvent to the salt – the layered material salts are large but dissolve into liquid similar to table salt in water. The fact that they form a liquid along with their negative charge, makes them easy to manipulate and use on a large scale, which is scientifically intriguing but also relevant to many industries,” said first author Dr Patrick Cullen.

|

|

“We’ve shown they can be painted onto surfaces and, when left to dry, can arrange themselves into different tiled shapes, which hasn’t been seen before. They can also be electroplated onto surfaces in much the same way gold is used to plate metals. We’re looking forward to making different 2D nanomaterials using our process and trying them out in different applications as the possibilities are near endless,” he concluded.

|