| Posted: Feb 08, 2017 |

Cracking the code for fissure control

(Nanowerk News) Cracks in a material typically compromise its strength and integrity, so research focus has traditionally been on preventing their occurrence and spread. An A*STAR team has now taken a different approach, prompting and directing the propagation of cracks on thin films to make highly-ordered patterned coatings for electrochromic materials (Nature Communications, "Ordered fragmentation of oxide thin films at submicron scale").

|

|

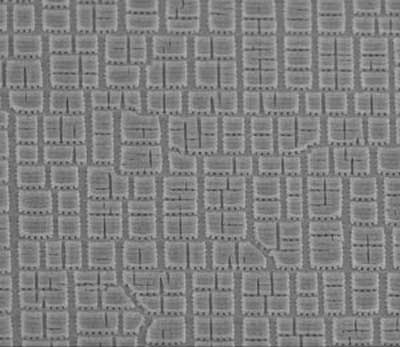

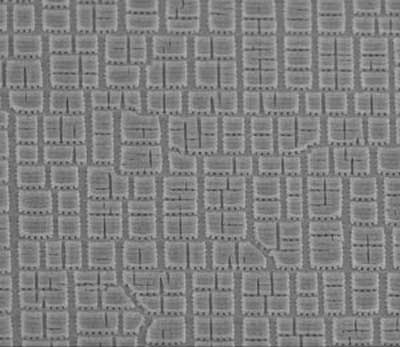

| A micrograph showing the highly-ordered cracked surface of a metal oxide thin film. (Image: A*STAR Institute of Materials Research and Engineering)

|

|

The transmission of light by electrochromic materials alters in response to brief bursts of electrical charge. They have optical uses ranging from the windows in Boeing 787-9 Dreamliners which change color at the touch of a button, to privacy glass around hotel bathrooms which switch between clear and opaque, to auto-dimming rear view car mirrors.

|

|

To feasibly expand the potential uses for these materials, scientists must reduce the amount of electrical power needed to modulate their optical property changes, explains team leader Sing Yang Chiam from the A*STAR Institute of Materials Research and Engineering. To achieve this, “devices will require a greater surface area of contact for enhanced interaction”, he says. “If you use nanoparticles for a large surface area, scattering makes for poor optical properties. Using a film with controlled cracks allows us to increase the surface area for better electrical efficiency, without sacrifice of the optical properties.”

|

|

Chiam’s team’s first step was to grow a thin NiO/Ni(OH)2 film on top of a regular array of pillars fixed to a rigid substrate. Such a structure introduced strain at pre-determined and regular points on the film. For example, spots with no support from any pillars were mechanically weak. The team found that briefly air-drying the newly-formed films was sufficient to trigger the crack formation at these locations. Further dehydration in a furnace caused the material to shrink and cause significant crack propagation.

|

|

Electron microscopy images showed that the cracking pattern on the surface was so ordered that it looked “artificially squarish” (see image), Chiam says. An unprecedented level of fragmentation control at the submicron and nanometer scale had been achieved.

|

|

Finally the team checked the electrochromic performance of the films using cyclic voltammetry measurements to measure their switching and optical properties. “The resultant structures yielded excellent electrochromic performance with high-coloration efficiency and stable cycling stability,” Chaim confirms.

|

|

“While the demonstrated enhancement is in electrochromics, I think the significance of the work is in the discovery of a method to order and control fragmentation at such a scale,” he adds.

|