| Posted: Feb 15, 2017 |

Metal-organic frameworks used as looms

(Nanowerk News) Researchers of Karlsruhe Institute of Technology (KIT) have made major progress in the production of two-dimensional polymer-based materials. To produce cloths from monomolecular threads, the scientists used SURMOFs, i.e. surface-mounted metal-organic frameworks, developed by KIT. They inserted four-armed monomers, i.e. smaller molecular building blocks, into some SURMOF layers. Cross-linking of the monomers then resulted in textiles consisting of interwoven polymer threads.

|

|

This work is now presented in Nature Communications ("Molecular weaving via surface-templated epitaxy of crystalline coordination networks").

|

|

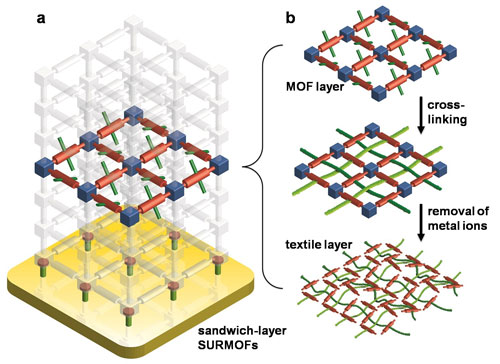

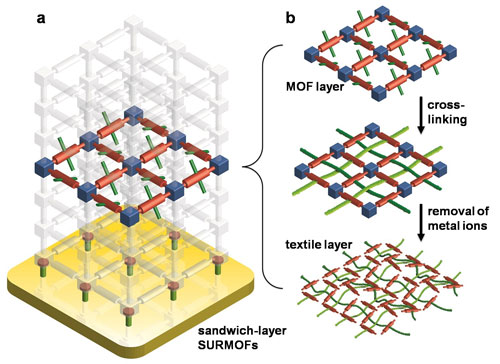

| The metal-organic framework is set up like a sandwich (a). The molecular textile layer is woven in an active layer that is embedded between so-called sacrificial layers (b). (Image: Karlsruhe Institute of Technology) (click on image to enlarge)

|

|

Self-organized cross-linking of polymer threads, i.e. of extremely long molecules, to two-dimensional tissues is a big challenge in polymer chemistry. With the help of a bottom-up process to cross-link smaller molecules, so-called monomers, scientists of the Institute of Functional Interfaces (IFG) and Institute of Nanotechnology (INT) of KIT now made an important step towards reaching this objective. They produced a tissue from monomolecular polymer threads by using SURMOFs, i.e. surface-mounted metal-organic frameworks, as looms. This approach is now presented in Nature Communications.

|

|

The SURMOFs developed by IFG are frameworks consisting of metallic node points and organic linkers that are assembled on a substrate layer by layer. They have a crystalline structure and can be customized to a large range of the applications by combining various materials and varying the pore sizes.

|

|

For weaving two-dimensional textiles, the KIT scientists specifically inserted special connection elements, i.e. four-armed monomers, into the SURMOF layers for later cross-linking. Then, these active SURMOF layers were embedded between so-called sacrificial layers.

|

|

“In this way, we produced a sandwich-type setup to ensure that the textiles produced really are two-dimensional, which means that they have a thickness of one molecule layer only,” Professor Christof Wöll says. He heads the IFG and is the corresponding author of the publication together with Professor Marcel Mayor of INT.

|

|

The scientists then applied a catalyst in these active SURMOF layers to start a reaction for linking the monomers to polymers. Afterwards, the metallic node points were removed. Flat tissues of monomolecular polymer threads remained.

|

|

“The polymer threads are kept together by the mechanical forces resulting from the weave pattern,” Marcel Mayor explains. “Hence, the molecular tissues are as flexible as textiles produced in a conventional way.”

|