| Posted: May 04, 2017 |

New models allow for extraction of oil trapped in nano-capillaries of reservoirs

(Nanowerk News) IBM scientists recently discovered that a drop of oil doesn't look like a drop at all if it is small, to the scale of one billionth of a billionth of a liter, or attoliter. Rather, a nanoscale oil droplet looks more like a flat film against a solid surface.

|

|

This discovery reveals that the simulation tools and techniques commonly employed by the oil industry do not take into account the increased energy required to extract these oil molecules. And it results in 60 percent or more of a well's oil being left behind, for example, in the nanoscale capillaries of shale reservoirs.

|

|

In response, IBM Research-Brazil is developing nanoscience-enhanced oil flow simulations that could better-predict oil extraction from a reservoir.

|

|

The scientists based at IBM's Nano Lab in Rio de Janeiro, led by Dr. Mathias Steiner, Manager, Industrial Technology & Science, recently published this research in a Scientific Reports study ("Adsorption energy as a metric for wettability at the nanoscale"), explaining how the properties of liquid oil molecules behave in completely different and unexpected ways when in contact with a solid material, at the nanoscale. Everything the industry knows about how to extract oil, such as calculating the energy it takes for extraction, turns out to be different at the nanoscale.

|

|

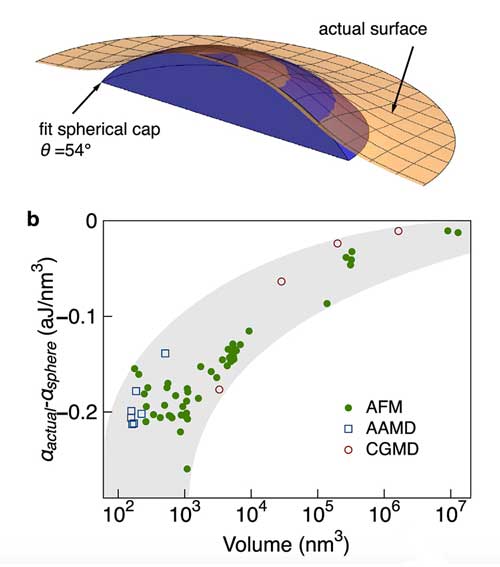

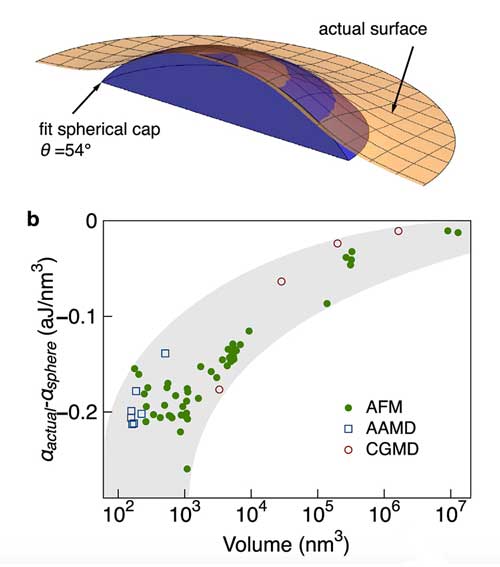

| Droplet adsorption energy: underestimated at the nanoscale. (a) Comparison of the actual surface with an idealized spherical cap fit to the same data. (b) Difference between adsorption energy for the actual surface and that of the spherical cap approximation. The negative differences indicate that the fitted spherical cap underestimates adsorption energy, just as it underestimates contact area. For volumes larger than 106 nm3 a spherical cap fit provides a robust estimate of the adsorption energy α. Acronyms: AFM-Atomic Force Microscope Measurement, AAMD-All Atom Molecular Dynamics Simulation, CGMD-Course Grain Molecular Dynamics Simulation. (© Scientific Reports)

|

|

Steiner's team also published a study in Nano Letters ("A Platform for Analysis of Nanoscale Liquids with an Array of Sensor Devices Based on Two-Dimensional Material"), detailing the novel measurement method for revealing nanoscale drop properties.

|

|

"These nano-wetting discoveries are an important step to help oil and gas companies to recover more of the oil trapped in their reservoirs. Just a 1 percent production enhancement, using the results of this research, would mean nearly a million more barrels of additional oil available each day, worldwide. The next step is to use the results obtained in this study to calibrate flow simulations of oil in nano-capillaries and their networks," Steiner said.

|

|

To that end, the IBM team has already developed a dedicated fluid-flow-on-chip platform that enables researchers to experimentally validate flow physics for building higher-accuracy simulations that connect flow at the nanoscale, with flow at larger scales.

|

|

By carrying out those flow simulations in computational three-dimensional representations of actual reservoir rock, the IBM research team is now developing an enhanced oil recovery advisor technology. This includes the computerized design and test of functional materials, such as nanoparticles, for enhanced oil extraction. Provided as a cloud-based IT service, the simulation technology will ultimately generate reservoir-specific recovery recommendations for industry experts who plan and manage oil production.

|