| Posted: Jun 14, 2017 |

Making wires of polymers chains

(Nanowerk News) Consumer demand continually pushes the electronics industry to design smaller devices. Now researchers at A*STAR have used a theoretical model to assess the potential of electric wires made from polymer chains that could help with miniaturization.

|

|

As conventional silicon-integrated circuits reach their lower size limit, new concepts are required such as molecular electronics — the use of electronic components comprised of molecular building blocks. Shuo-Wang Yang at A*STAR Institute of High Performance Computing together with his colleagues and collaborators, are using computer modeling to design electric wires made of polymer chains.

|

|

“It has been a long-standing goal to make conductive molecular wires on traditional semiconductor or insulator substrates to satisfy the ongoing demand miniaturization in electronic devices,” explains Yang.

|

|

Progress has been delayed in identifying molecules that both conduct electricity and bind to substrates. “Structures with functional groups that facilitate strong surface adsorption typically exhibit poor electrical conductivity, because charge carriers tend to localize at these groups,” he adds.

|

|

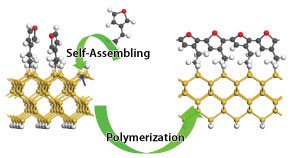

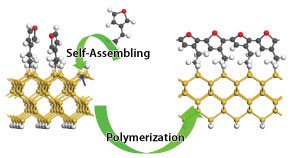

| A two-step synthesis of molecular wires was studied using molecular modeling. (© American Chemical Society)

|

|

Yang’s team applied density functional theory to a two-step approach for synthesizing linear polymer chains on a silicon surface ("How to Fabricate a Surface-Grafted Polythiophene on H-Si(100)2×1 Surface via Self-Assembling and in Situ Surface Polymerization: A Theoretical Guide" and "Theoretical study on the self-assembly of 1,3,5-triethynylbenzene on Si(100)2 × 1 and in situ polymerization via reaction with CO to fabricate a single surface-grafted polymer "). “This theory is the best simulation method for uncovering the mechanism behind chemical reactions at atomic and electronic levels. It can be used to predict the reaction pathways to guide researchers,” says Yang.

|

|

The first step is the self-assembled growth of single monomers on to the silicon surface. Yang’s team studied several potential monomers including, most recently, a thiophene substituted alkene1 and a symmetrical benzene ring with three alkynes attached. The second step is the polymerization of the tethered monomers by adding a radical to the system.

|

|

According to the calculations, these tethered polymers are semiconductors in their natural state. “We introduced some holes, such as atomic defects, to the wires to shift the Fermi levels and make them conductive,” Yang explains.

|

|

The team then studied the electron band structures of each component before and after tethering and polymerization; finding little charge transfer between the molecular wires and the silicon surfaces. “The surface-grafted polymers and underlying substrates seem independent of each other, which is an ideal model of a conductive molecular wire on a traditional semiconductor substrate,” says Yang.

|

|

“Our finding provides a theoretical guide to fabricating ideal molecular wires on traditional semiconducting surfaces,” he adds. The team is plans to extend their work to study 2D analogs of these 1D polymer chains that could work as a metallic layer in molecular electronic devices.

|