| Posted: Aug 09, 2017 |

Engineers pioneer platinum shell formation process - and achieve first-ever observation

(Nanowerk News) UCI researchers have devised a new method of dynamically forming a platinum shell on a metallic alloy nanoparticle core, a development that may lead to better materials for oxygen reduction reactions in fuel cells that power some cars and electronic devices.

|

|

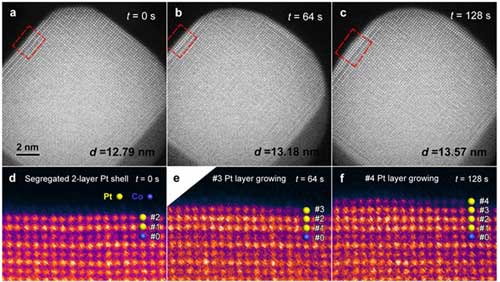

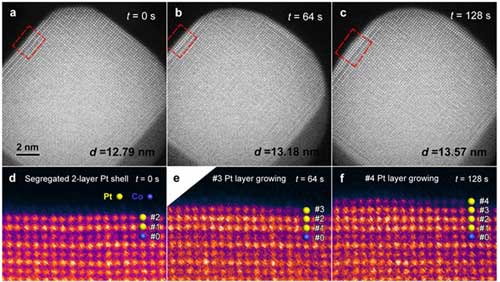

In a first, engineers were able to observe the process directly, in real time, in UCI’s state-of-the-art transmission electron microscopy facility, part of the recently established Irvine Materials Research Institute.

|

|

| A shell of platinum grows layer by layer during oxygen annealing. (Image: Pan Group / UCI) (click on image to enlarge)

|

|

Reported in Nature Communications ("In situ atomic-scale observation of oxygen-driven core-shell formation in Pt3Co nanoparticles"), the method centers on an oxygen annealing treatment to enrich the concentration of the metal on the platinum-cobalt nanomaterial core, a more effective procedure than traditional acid leaching or reductive annealing, according to the research team.

|

|

“A deeper understanding of platinum shell formation is critical for synthesis and structural control of platinum-metallic nanoparticles,” said team leader Xiaoqing Pan, Henry Samueli Endowed Chair in Engineering and professor of chemical engineering & materials science at UCI. “We were able to achieve atomic-scale observation of the reaction process at atmospheric pressures in our TEM, something that has never been successfully accomplished until now.”

|

|

Pan, who’s also the inaugural director of the Irvine Materials Research Institute and a professor of physics & astronomy, said his group’s work “may open a new avenue to study gas-solid interactions at atomic scale under the atmospheric pressure at which many real gas-phase reactions take place.” The project was supported by IMRI and the National Science Foundation.

|