| Posted: Oct 16, 2017 |

Long nanotubes make strong fibers

(Nanowerk News) To make continuous, strong and conductive carbon nanotube fibers, it’s best to start with long nanotubes, according to scientists at Rice University.

|

|

The Rice lab of chemist and chemical engineer Matteo Pasquali, which demonstrated its pioneering method to spin carbon nanotube into fibers in 2013, has advanced the art of making nanotube-based materials with two new papers in ACS Applied Materials and Interfaces.

|

|

The first paper ("Influence of Carbon Nanotube Characteristics on Macroscopic Fiber Properties") characterized 19 batches of nanotubes produced by as many manufacturers to determine which nanotube characteristics yield the most conductive and strongest fibers for use in large-scale aerospace, consumer electronics and textile applications.

|

|

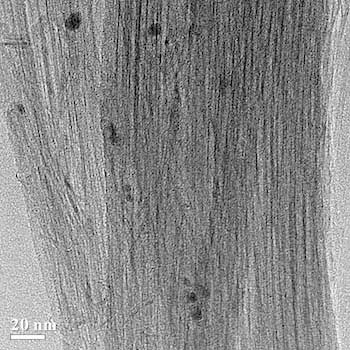

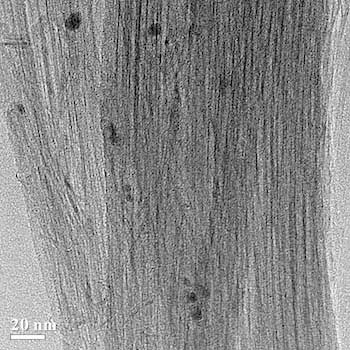

| Iron impurities are easy to see in a bundle of carbon nanotubes viewed through a transmission electron microscope. Researchers at Rice University and the National University of Singapore are leading the charge to purify nanotubes for use in continuous, strong and conductive carbon nanotube fibers. (Image: Pasquali Group)

|

|

The researchers determined the nanotubes’ aspect ratio — length versus width — is a critical factor, as is the overall purity of the batch. They found the tubes’ diameters, number of walls and crystalline quality are not as important to the product properties.

|

|

Pasquali said that while the aspect ratio of nanotubes was known to have an influence on fiber properties, this is the first systematic work to establish the relationship across a broad range of nanotube samples. Researchers found that longer nanotubes could be processed as well as shorter ones, and that mechanical strength and electrical conductivity increased in lockstep.

|

|

The best fibers had an average tensile strength of 2.4 gigapascals (GPa) and electrical conductivity of 8.5 megasiemens per meter, about 15 percent of the conductivity of copper. Increasing nanotube length during synthesis will provide a path toward further property improvements, Pasquali said.

|

|

The second paper ("Purification and Dissolution of Carbon Nanotube Fibers Spun from the Floating Catalyst Method") focused on purifying fibers produced by the floating catalyst method for use in films and aerogels. This process is fast, efficient and cost-effective on a medium scale and can yield the direct spinning of high-quality nanotube fibers; however, it leaves behind impurities, including metallic catalyst particles and bits of leftover carbon, allows less control of fiber structure and limits opportunities to scale up, Pasquali said.

|

|

“That’s where these two papers converge,” he said. “There are basically two ways to make nanotube fibers. In one, you make the nanotubes and then you spin them into fibers, which is what we’ve developed at Rice. In the other, developed at the University of Cambridge, you make nanotubes in a reactor and tune the reactor such that, at the end, you can pull the nanotubes out directly as fibers.

|

|

“It’s clear those direct-spun fibers include longer nanotubes, so there’s an interest in getting the tubes included in those fibers as a source of material for our spinning method,” Pasquali said. “This work is a first step toward that goal.”

|

|

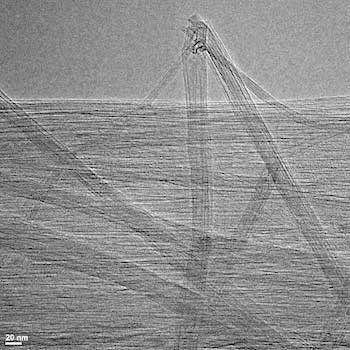

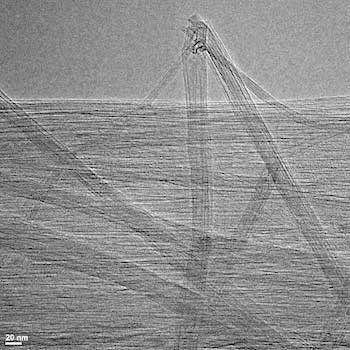

| A transmission electron microscope image of purified carbon nanotubes. Researchers at Rice University and the National University of Singapore are developing a process to remove impurities from batches of long nanotubes to spin them into continuous, conductive fibers. (Image: Pasquali Lab)

|

|

The reactor process developed a decade ago by materials scientist Alan Windle at the University of Cambridge produces the requisite long nanotubes and fibers in one step, but the fibers must be purified, Pasquali said. Researchers at Rice and the National University of Singapore (NUS) have developed a simple oxidative method to clean the fibers and make them usable for a broader range of applications.

|

|

The labs purified fiber samples in an oven, first burning out carbon impurities in air at 500 degrees Celsius (932 degrees Fahrenheit) and then immersing them in hydrochloric acid to dissolve iron catalyst impurities.

|

|

Impurities in the resulting fibers were reduced to 5 percent of the material, which made them soluble in acids. The researchers then used the nanotube solution to make conductive, transparent thin films.

|

|

“There is great potential for these disparate techniques to be combined to produce superior fibers and the technology scaled up for industrial use,” said co-author Hai Minh Duong, an NUS assistant professor of mechanical engineering. “The floating catalyst method can produce various types of nanotubes with good morphology control fairly quickly. The nanotube filaments can be collected directly from their aerogel formed in the reactor. These nanotube filaments can then be purified and twisted into fibers using the wetting technique developed by the Pasquali group.”

|

|

Pasquali noted the collaboration between Rice and Singapore represents convergence of another kind. “This may well be the first time someone from the Cambridge fiber spinning line (Duong was a postdoctoral researcher in Windle’s lab) and the Rice fiber spinning line have converged,” he said. “We’re working together to try out materials made in the Cambridge process and adapting them to the Rice process.”

|