| Posted: Nov 17, 2017 |

World's first real-time visualization of water produced inside fuel cells

(Nanowerk News) As part of the NEDO project, Tokyo Institute of Technology (Tokyo Tech) has successfully developed the world's first technology capable of visualizing, in real-time and in high-resolution, the behaviors of the water produced inside operating fuel cells. As a result of this breakthrough, it is now possible to observe the behavior of the water produced in fuel cells for automobiles which often experience drastic changes in reactions. The technology is expected to accelerate improvements in fuel cells that will enable higher performance and better durability and to accelerate technology development that will contribute to new design guidelines.

|

|

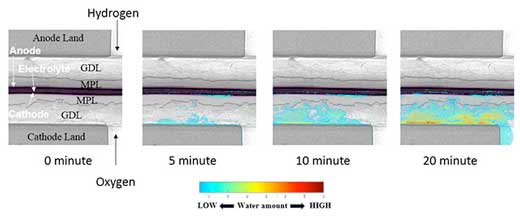

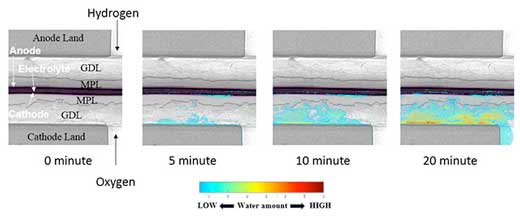

| Figure 1. Visualization of the change in reaction-produced water over time (inside a fuel cell producing electricity). Land: The path feeding gas to the fuel cell is formed of ridges and crevices. The ridges are called land. They receive contact through the membrane electrode assembly (MEA) and the diffusion layer and act as the component which conducts electricity. The crevices are called channels and act as the pathway for feeding gas into the fuel cell as well as for eliminating water and other wastes. GDL: The acronym for gas diffusion layer. Its function is to efficiently lead the air and hydrogen required for the chemical reaction. MPL: The acronym for micro-porous layer. It is used to adjust material transfer as a part of the GDL. (Image: Tokyo Tech)

|

|

Compilation of the Revised Version of the Strategic Roadmap for Hydrogen and Fuel Cells, formulated by the Ministry of Economy, Trade and Industry of Japan in 2014 toward the realization of a hydrogen society, sets as the distribution target "about 800 thousand vehicles by 2030" by drastically reducing the cost of fuel cell systems for the wider adoption of fuel cell automobiles. NEDO has set the values which would be required of fuel cells for fuel cell vehicles (FCV) by the time they are widely distributed in 2025 and beyond (stack power density over 4 kW/L, durability over 50,000 hours, etc.), and, since 2015, has been working on projects with the aim of developing technologies for precise analysis and evaluation of fuel cells and those which would contribute to design guidelines for new materials.

|

|

Fuel cells are systems which use catalysts to make hydrogen react with the oxygen in the air (the fed gas), then convert into electricity the energy generated when water is produced. This liquid water which is produced is known, at times, to interfere with the oxygen feeding by pooling inside the fuel cell. To accurately observe the behavior of the produced water has been one important issue in improving performance of fuel cells. Conventionally, however, it had been determined indirectly based on the cell's performance in generating electric power.

|

|

At this time, the NEDO project led by the Fuel Cell Cutting-Edge Research Center Technology Research Association (FC-Cubic TRA)1 and Tokyo Tech's Professor Shuichiro Hirai's group has developed, for the first time worldwide, a technology capable of visualizing the behavior of water produced inside fuel cells in high resolution of the order of a micrometer in real-time.

|

Technological achievement

|

|

Polymer electrolyte fuel cells (PEFC) for vehicles require improvement in durability and performance characteristics suitable for a variety of classes from passenger to commercial automobiles. Additionally, each fuel cell manufacturer is also developing ways to reduce costs so that the cost for FCV is on par with the cost for gasoline engine vehicles.

|

|

To accelerate the solutions to these technological issues, the FC-Cubic TRA and others are working on NEDO projects with the research theme "Analysis and cell evaluation highly linked to catalysts, electrolytes, or MEA internal phenomena" on fundamental development research for fuel cells for vehicles such as understanding phenomena. As a part of this theme, Professor Hirai of Tokyo Tech and his group have been focusing on the research and development of visualizing water produced inside fuel cells during operation using X-rays, especially at increased resolutions.

|

|

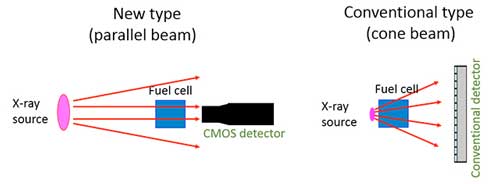

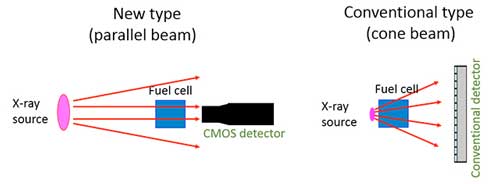

Until now, there was no apparatus which could visualize water produced inside operating fuel cells at a high resolution over a prolonged period. At this time, the team was successful in combining technology for parallel X-ray beams2 and CMOS sensors3 as well as in devising adjustments to the fuel cell for observation4 to create an apparatus which can produce a high-resolution visualization and is a size which can be installed inside a laboratory. They were able to develop a technology to measure the behavior of water produced during the reaction inside fuel cells at each layer and interface?which greatly affects the cells' power generation characteristics?at the micrometer level.

|

|

| Successful in combining technology for parallel X-ray beams and CMOS sensors as well as devising adjustments to the fuel cell for observation to produce a high-resolution visualization. (Image: Tokyo Tech)

|

|

As a result of this achievement, it is now possible to observe the behavior of the water produced by the reaction inside operating fuel cells (at each layer and interface), where reaction behaviors experience drastic changes. This will contribute greatly to fuel cell design.

|

|

Tokyo Tech will take this achievement and commence collaborative research with corporations and others. This is expected to accelerate the development of technology for fuel cells aiming for the further increase in performance and durability and the decrease in cost required by the motor vehicle industry.

|

|

This research achievement was announced on October 5 at the 232nd meeting of the Electrochemical Society held on October 1 to 5, 2017.

|

Notes

|

|

1 Fuel Cell Cutting-Edge Research Center Technology Research Association (FC-Cubic TRA)

|

|

Established on April 2, 2010 with the participation of fuel cell-related industrial members, universities, and the National Institute of Advanced Industrial Science and Technology. Its activity is to research common foundations which would support the development of fuel cells and their systems in industrial fields.

|

|

2 Technology for parallel X-ray beams

|

|

Conventional X-ray beams are emitted radially from its source. This technology makes it possible to emit them parallel to one another.

|

|

3 CMOS sensors

|

|

A type of component which converts light into electronic signals. In theory, it has the characteristic of pixels having minimal effect on one another, and the resolution has become higher with recently developed technology.

|

|

4 Fuel cell for observation

|

|

In order to visualize the water inside the fuel cell with X-rays, the components of the cell are designed thinner to reduce the effect of X-ray absorption.

|