| Posted: Nov 28, 2017 |

Addition of tin boosts nanoparticle's photoluminescence

(Nanowerk News) Researchers at the U.S. Department of Energy’s Ames Laboratory have developed germanium nanoparticles with improved photoluminescence, making them potentially better materials for solar cells and imaging probes. The research team found that by adding tin to the nanoparticle’s germanium core, its lattice structure better matched the lattice structure of the cadmium-sulfide coating which allows the particles to absorb more light (Chemistry of Materials, "Germanium–Tin/Cadmium Sulfide Core/Shell Nanocrystals with Enhanced Near-Infrared Photoluminescence").

|

|

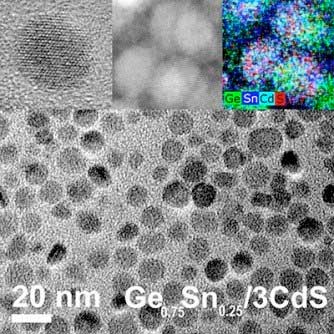

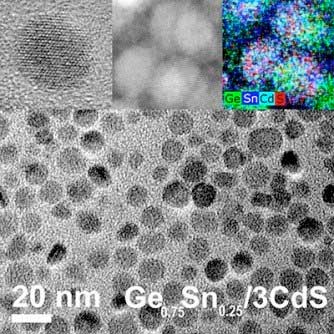

| Electron microscopy images of germanium-tin nanoparticles with a cadmium-sulfide coating. (Image: Ames Laboratory)

|

|

“For a photovoltaic material, obviously absorbing light is the first part and converting that solar energy into electrical energy is the second part,” said Ames Laboratory scientist Emily Smith. “So you want a material that does both efficiently. Germanium has some desirable characteristics for photovoltaic materials, but unfortunately it doesn’t absorb light well.”

|

|

Part of the problem is that the outside surface of germanium nanoparticles changes over time, primarily from oxidation. Previous work by Ames Laboratory scientist Javier Vela’s group found that coating nanoparticles—commonly referred to as surface passivation—improved the nanoparticles’ ability to absorb light.

|

|

“We aren’t actually measuring absorption,” Smith explained, “we measure the luminescence – the amount light given off after a photon is absorbed. ”

|

|

“The fact that germanium doesn’t absorb light well is a simple way of saying it’s an indirect bandgap material,” Smith added, “and we are trying to make a more direct bandgap material, one that absorbs light better.”

|

|

According to the research literature, the addition of tin appears to improve germanium’s light absorption properties. However, the Ames Laboratory researchers found that even with adding tin, the nanoparticles still required a surface coating. But they also discovered that the relationship between the atomic structure of surface coating and the core material can further enhance the light absorption.

|

|

The specific method used is called Successive Ion Layer Adsorption and Reaction or 'SILAR', which was first adapted to group IV colloids several years ago.

|

|

"We have been developing the expertise required to grow intricate core/shell and other well defined nanoparticles for many years," Vela said, “Through our collaboration with Emily Smith’s group, we hope to continue making inroads in our ability to manipulate and direct energy flows at the nanoscale."

|

|

Using transmission electron microscopy imaging and powder X-ray diffraction to study the structural characteristics of the nanoparticles and Raman and photoluminescence spectroscopies to quantify lattice strain and photoluminescence behavior, the group found a correlation between the amount of tin in the core and how well the core’s lattice matched that of the cadmium-sulfide outer shell.

|

|

“The atoms are in a very specific location within the nanocrystal core and when you apply the shell around the nanocrystal, the atoms of the shell may not match perfectly with the atoms of the core,” Smith said. “With the germanium only material used previously, the core and shell didn’t match perfectly.”

|

|

“When we studied the germanium-tin particles, we proposed that they worked better because the spacing of the atoms better matches the spacing of the atoms we used in the coat layer,” she said. “By doing that, you’re getting a more perfect shell that’s less likely to cause chemical changes to the surface of the nanoparticle core.”

|

|

Another potential use for this material, besides photovoltaics, is that in microscopy or imaging, researchers often need to “label” a protein or other feature with a nanoparticle “probe” to make it light up so it is easier to see and study.

|