| Posted: Jan 15, 2018 |

Solar fuels: better efficiency using microwires

(Nanowerk News) Researchers at the University of Twente’s MESA+ Institute for Nanotechnology have made significant efficiency improvements to the technology used to generate solar fuels. This involves the direct conversion of energy from sunlight into a usable fuel (in this case, hydrogen).

|

|

Using only earth-abundant materials, they developed the most efficient conversion method to date. The trick was to decouple the site where sunlight is captured from the site where the conversion reaction takes place.

|

|

This study was published today in the journal Nature Energy ("Spatial Decoupling of Light Absorption and Catalytic Activity of Ni-Mo-Loaded High-Aspect-Ratio Silicon Microwire Photocathodes").

|

|

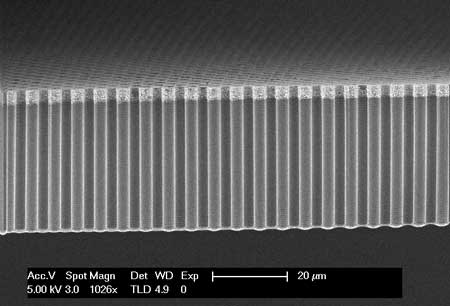

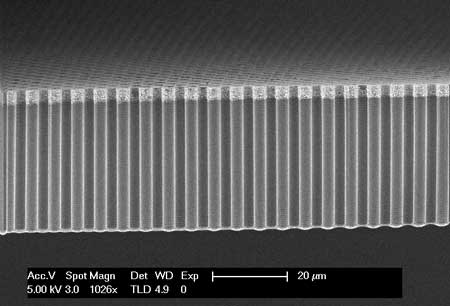

| Microwires for solar fuel conversion. (Image: University of Twente)

|

|

Researchers around the world are working on the development of solar fuel technology. This involves generating sustainable fuels using only sunlight, CO2 and water, the basic ingredients used by plants. A group of researchers from the University of Twente’s MESA+ research institute are working on a solar-to-fuel device that produces hydrogen. They have now achieved a major breakthrough in this area of fundamental research.

|

|

Using earth-abundant materials (i.e. avoiding the use of scarce and expensive precious metals), they have developed the most efficient method to date for converting light into hydrogen. The system consists of silicon microwires less than one tenth of a millimetre long, the tops of which are coated with a catalyst. The photons (light particles) are collected between the microwires. The chemical reaction in which hydrogen is formed takes place on the catalyst at the tips of the microwires.

|

Decoupling

|

|

By varying the density and length of the microwires, the researchers ultimately achieved a maximum efficiency of 10.8 percent. They managed to achieve this by decoupling the site where the photons are collected from the site where the conversion reaction takes place. This is necessary because catalysts usually reflect light.

|

|

Yet – to make the conversion as efficient as possible – you want them to absorb as much light as possible. It is important to achieve this decoupling at the microscale, because at larger scales the conductivity of the silicon microwires becomes the limiting factor.

|

|

Prof. Jurriaan Huskens, one of the researchers involved, states that 10.8 percent is the highest ever efficiency for a silicon-based design. However, a further increase in efficiency – to fifteen percent – is needed to make the technology economically viable.

|